A kind of activated carbon material that can be used for supercapacitor electrode and preparation method thereof

A supercapacitor and activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low specific capacity, unfavorable electric double layer, and high production cost of supercapacitor electrode materials, and achieve low cost and overcome corrosion The effect of strong resistance and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] One of preparation technology that the present invention adopts is to preconfigure composite activator solution, in described step (1), alkali and phosphorus compound are dissolved in distilled water after mixing by certain mass ratio, and alkali and phosphorus compound are mixed according to 1:(0.1~ 5) are mixed in a mass ratio, and the amount of distilled water is 0.5 to 10 times the total mass of the alkali and the phosphorus compound.

[0041] The alkali and phosphorus compound for configuring the composite activator solution, the alkali can be NaOH, KOH, etc., and the phosphorus compound can be sodium phosphate, potassium phosphate, sodium hydrogen phosphate, potassium hydrogen phosphate, etc.

[0042] In the step (1), sodium hydroxide and sodium phosphate are mixed and then dissolved in distilled water, stirred evenly and then placed for 0.1 to 10 hours.

[0043] The added amount of the petroleum coke powder is 0.1-1 times of the total mass of the alkali and the p...

Embodiment 1

[0057] Mix 12g of sodium hydroxide and 7.2g of sodium phosphate and dissolve in 30mL of distilled water, stir evenly, cool to room temperature, add 6g of petroleum coke powder and 1.2mL of ethanol (chemically pure) into it, stir evenly and place it for 60min to obtain a mixture . Stir the mixture at 60°C for 1 hour, heat and dry at 150°C in the atmosphere, then place it in an activation furnace, raise the temperature of the furnace to 700°C at a rate of 5°C / min under the protection of nitrogen, and heat-preserve and activate After 1h, it was cooled to room temperature with the furnace, then pickled with hydrochloric acid with a concentration of 5mol / L, then washed with distilled water until neutral, and dried in a vacuum oven at 100°C for 10h to obtain a phosphorus-containing composite activated carbon. Get 0.8g phosphorus-containing composite activated carbon, mix phosphorus-containing composite activated carbon, conductive carbon black, and polytetrafluoroethylene evenly in ...

Embodiment 2

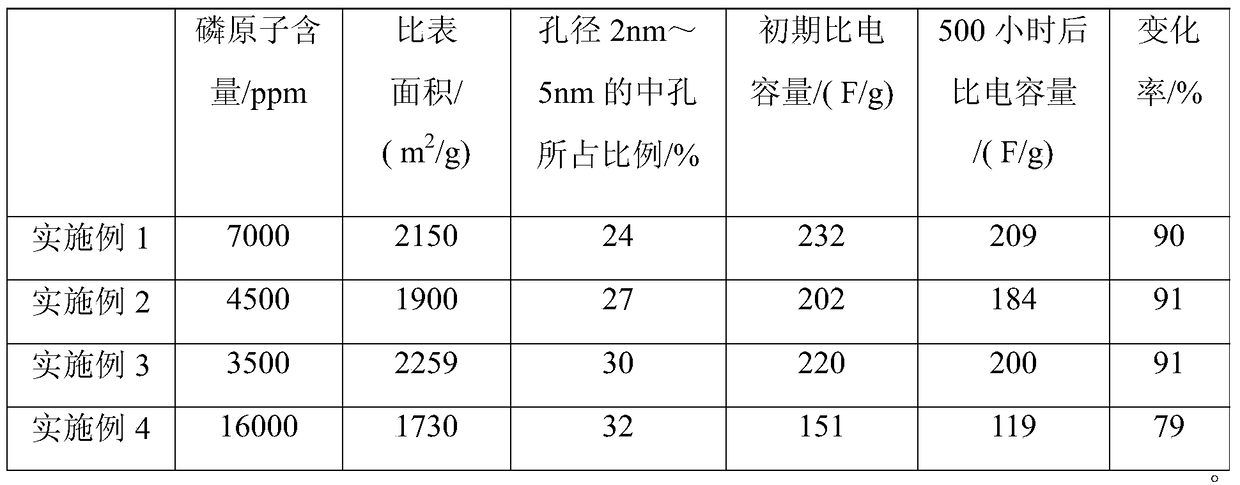

[0059] Mix 8g of sodium hydroxide and 2.4g of sodium phosphate and dissolve in 20mL of distilled water, stir evenly, cool to room temperature to obtain a composite activator solution, add 2g of petroleum coke powder and 0.5mL of ethanol (chemically pure) to it, stir evenly and place 60min, the mixture was obtained. The mixture was stirred for 2 hours at a temperature of 70°C, heated and dried at 150°C in the atmosphere, then placed in an activation furnace, and the temperature of the furnace was raised to 800°C at a rate of 10°C / min under the protection of nitrogen. After heat preservation and activation for 1 h, it was cooled to room temperature with the furnace, followed by pickling, water washing, and drying operations as in Example 1 to obtain phosphorus-containing composite activated carbon. The electrode preparation method, battery assembly, and test conditions are the same as in Example 1. The test data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com