Carbon shell-coated lead molybdate nanocrystal and preparation method thereof

A nanocrystal, lead molybdate technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of affecting the photocatalytic efficiency, reducing the conductivity of the material, and the complexity of the process. Separation and transfer, low cost, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Synthesis of lead molybdate nanocrystals coated with 2 nanometer carbon shells

[0025] First, lead acetate trihydrate (75.9 mg) and ammonium molybdate (35.3 mg) were added to a Teflon liner with a volume of 20 mL at room temperature, followed by 12.0 mL of deionized water with a pipette Into a Teflon liner, the solution obtained above was placed on a magnetic stirrer and stirred for 10 min.

[0026] 105.0 mg of citric acid were added to the above solution, and the solution obtained in the above reaction liner was stirred for 5 minutes on a magnetic stirrer.

[0027] Next, put the reaction liner containing the precursor solution into the stainless steel shell of the reaction kettle, tighten the lid of the kettle, and then put the reaction kettle into a 200-degree electric blast drying oven and keep it for 1 hour.

[0028] After the reaction, cool the removed reactor to room temperature, transfer the solution in the reaction liner to a 10ml centrifuge tube...

Embodiment 2

[0030] Example 2: Lead molybdate nanocrystals coated with 5 nanometer carbon shells

[0031] Except for adding 210.0 mg of citric acid, the same method as in Example 1 was used to prepare lead molybdate nanocrystals coated with 5 nanometer carbon shells.

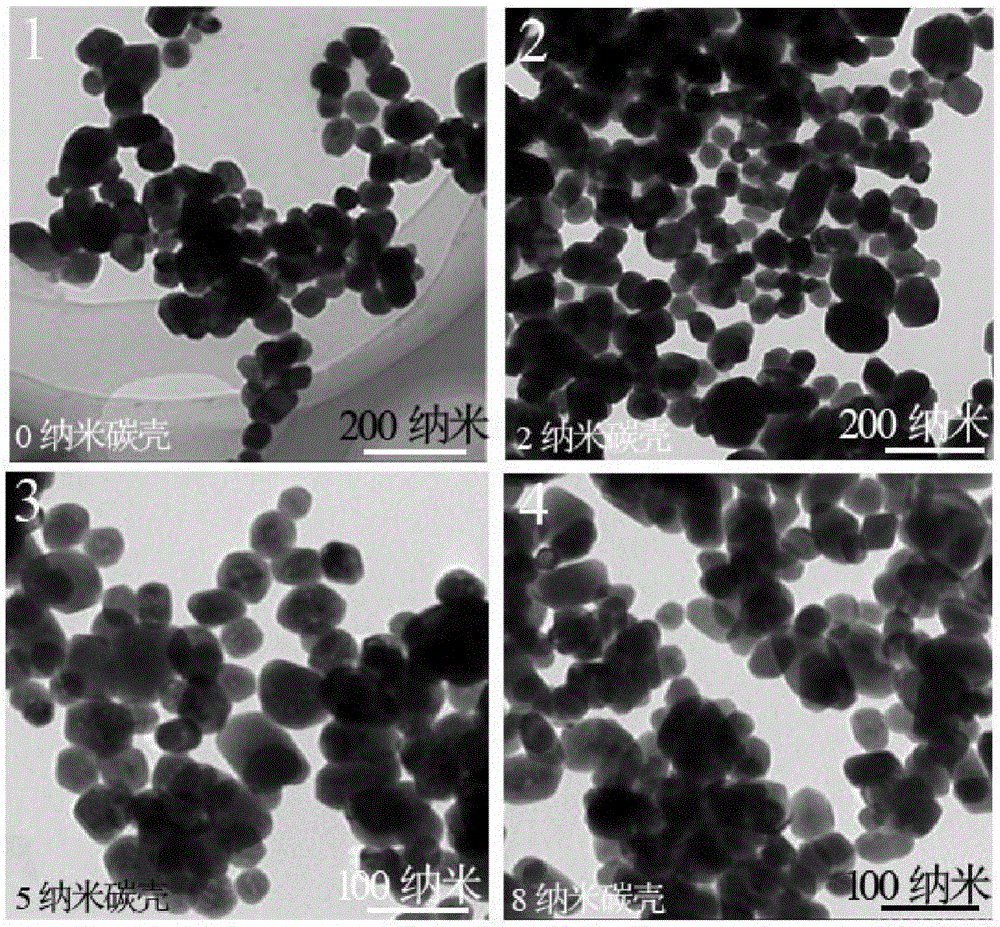

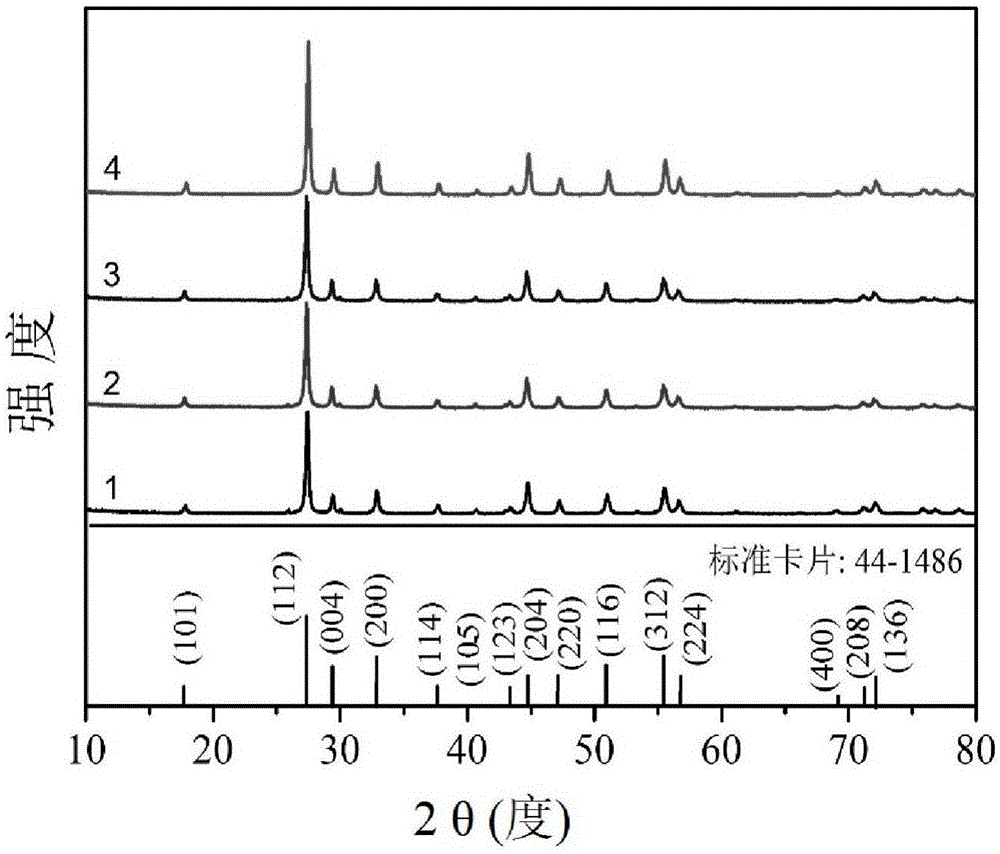

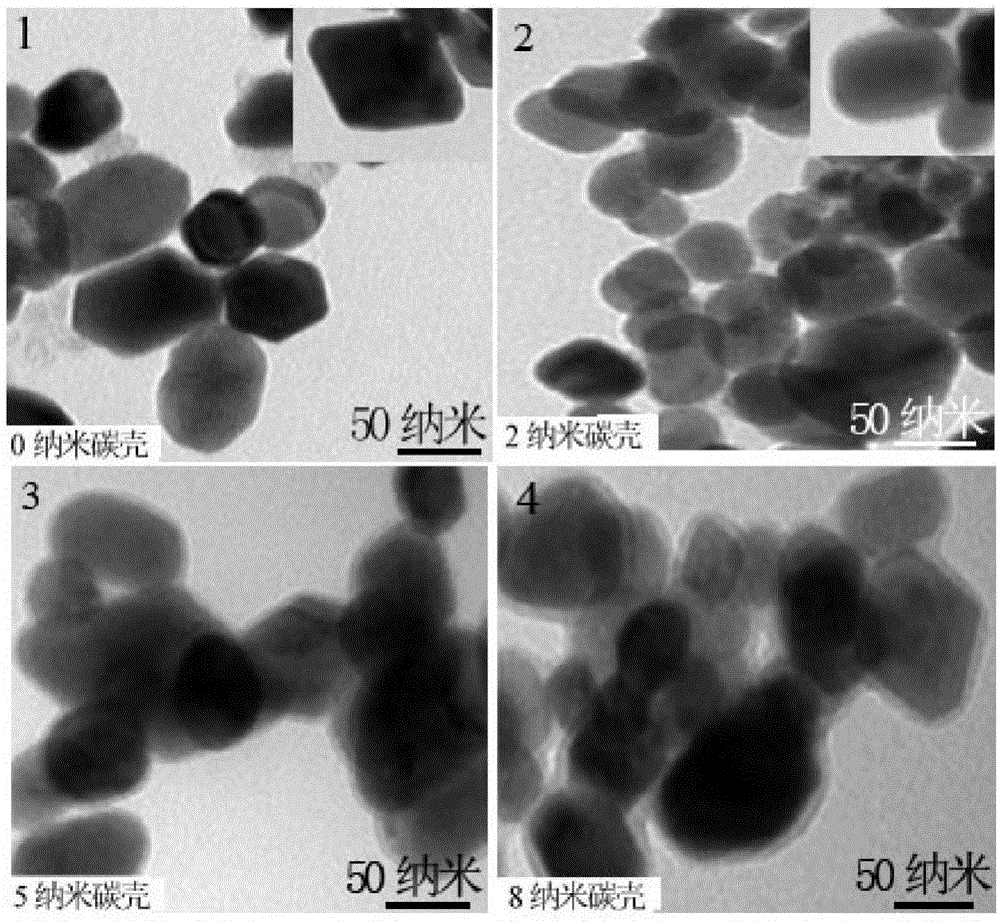

[0032] figure 1 Photo 2 is a transmission electron micrograph of the final product prepared in this embodiment, which shows that the prepared length and width are about 50 to 100 nanometers and 20 to 50 nanometers; figure 2 Curve 3 among them is the X-ray powder diffraction pattern of the final product prepared in this embodiment, as can be seen from the figure, the crystallinity of the product synthesized under hydrothermal conditions is high; image 3 Photo 3 in is the high-resolution electron micrograph of the final product prepared in this embodiment; Figure 4 Curve 3 is the Raman spectrum of the final product prepared in this example. In this Raman spectrum, there are absorption bands D band and G band, and its posi...

Embodiment 3

[0033] Example 3: Lead molybdate nanocrystals coated with 8 nanometer carbon shells

[0034] Except that 1050 mg of citric acid was added, lead molybdate nanocrystals coated with 8 nanometer carbon shells were prepared according to the same method as in Example 1.

[0035] figure 1 Photo 3 is a transmission electron microscope photo of the final product prepared in this embodiment, which shows that the prepared length and width are about 50 to 100 nanometers and 20 to 50 nanometers; figure 2 Curve 4 among them is the X-ray powder diffraction pattern of the final product prepared in this embodiment, as can be seen from the figure, the crystallinity of the product synthesized under hydrothermal conditions is high; image 3 Photo 4 in is the high-resolution electron micrograph of the final product prepared in this embodiment; Figure 4 Curve 4 is the Raman spectrogram of the final product prepared in this example. In this Raman spectrum, there are absorption bands D band and G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com