Method for extracting, separating and purifying honokiol and magnolol from magnolia officinalis

A technology for separating and purifying honokiol, applied in the field of honokiol and honokiol extraction, can solve the problems of cumbersome operation process, lack of theoretical guidance, difficult selection of solvent system, etc., and achieve the effect of low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: the method for extracting, separating and purifying honokiol and magnolol from Magnolia officinalis, its steps are:

[0026] (1) Extraction of Magnolia officinalis Lignin: Pulverize Magnolia officinalis medicinal material, ultrasonically extract 3 times with 10 times the amount of 80% ethanol, each time for 45 minutes, filter, combine the extracts, and concentrate under reduced pressure to obtain a crude extract.

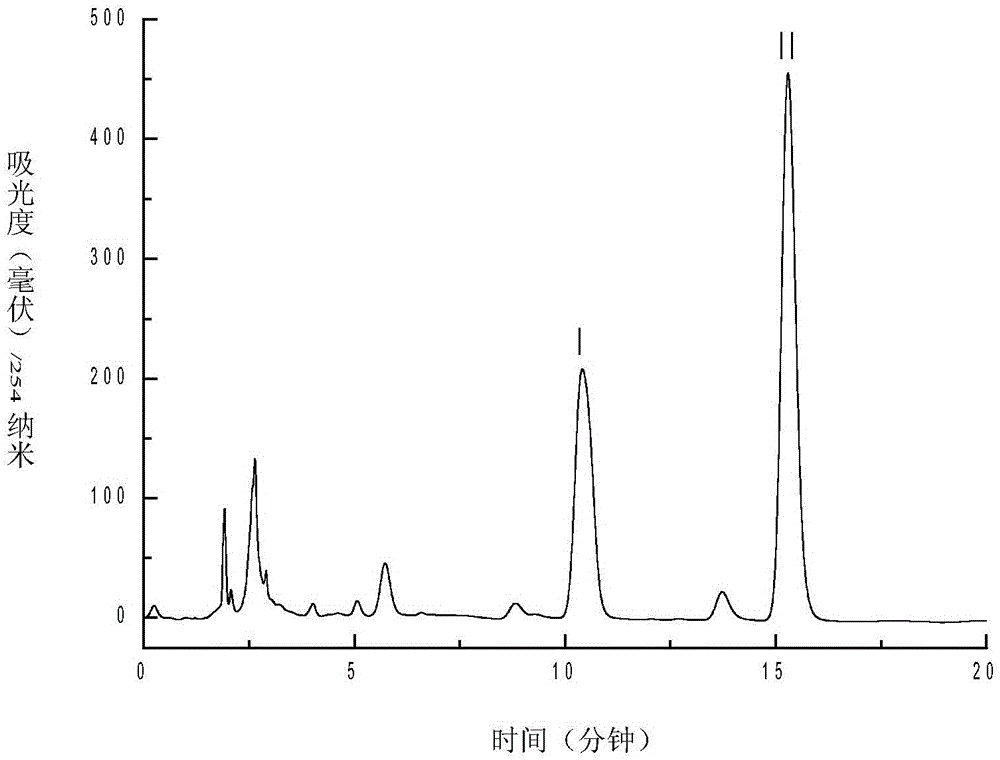

[0027] (2) Separation and analysis of magnolia lignin: use analytical high performance liquid chromatography to separate and analyze the composition of the crude extract, and the chromatographic column is C 18 Column (250×4.6mm I.D., 5μm), the mobile phase is methanol-water (73:27, V / V); the flow rate is 1.0mL / min, the detection wavelength is 254nm, and the column temperature is room temperature.

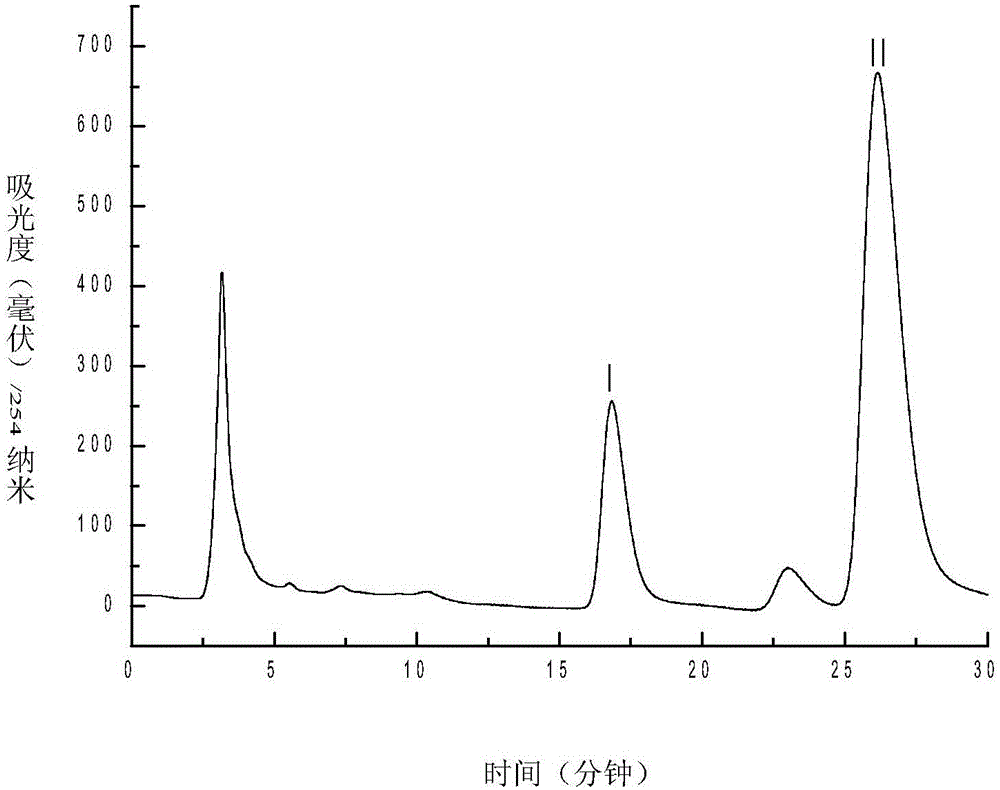

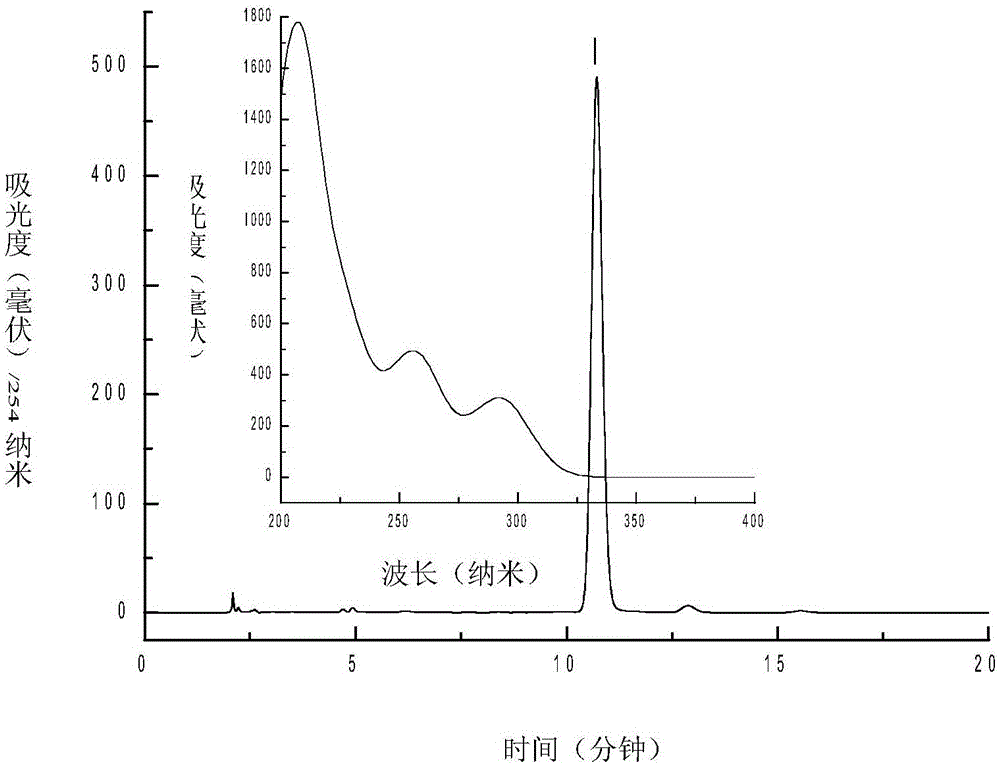

[0028] (3) Separation and purification of magnolia lignin: use a semi-preparative high-performance liquid chromatograph to separate and purify the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com