Petroleum sulfoxide and preparation method thereof

A technology for petroleum sulfoxide and high-sulfur crude oil, which is applied in the field of chemical extraction, can solve the problems that are not conducive to improving the production efficiency of petroleum sulfoxide, high oxidation temperature, and strong volatility of benzene, so as to speed up the oxidation reaction rate, improve the production efficiency, The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

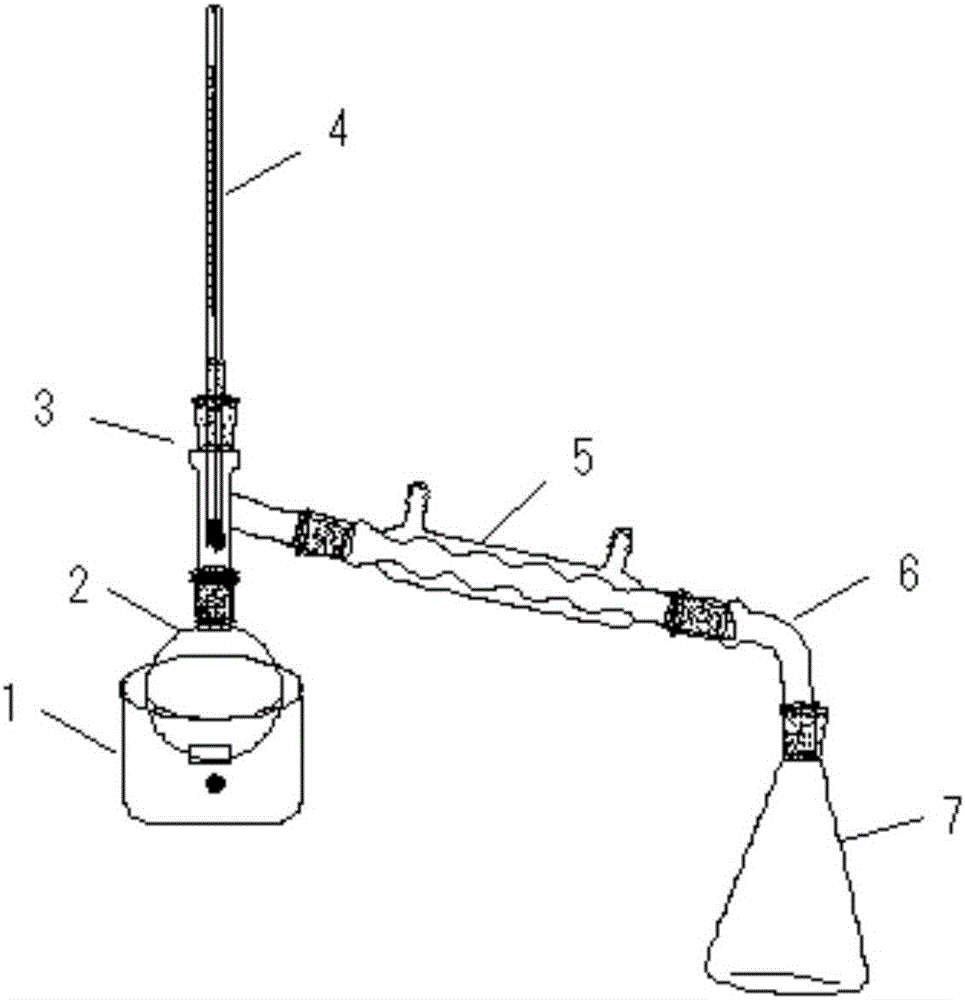

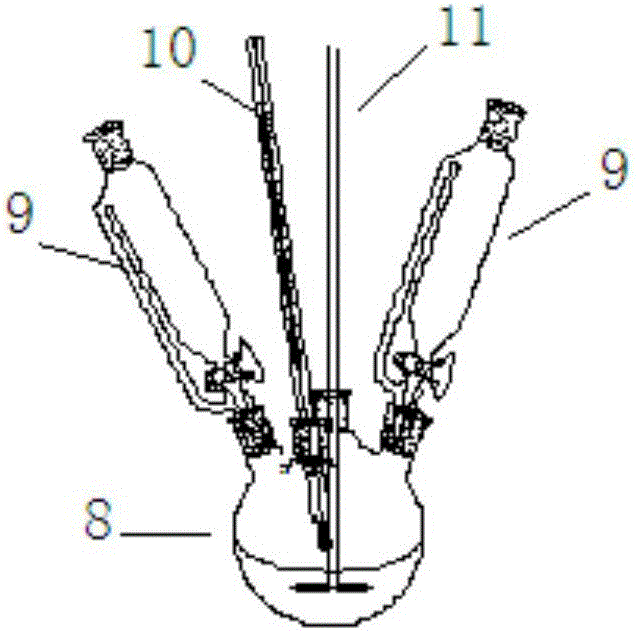

Embodiment 1

[0022] Take 800ml of crude oil in a round-bottomed flask, heat it to carry out normal pressure boiling point distillation, collect fractions at 275-325°C and 325-350°C respectively, and measure the total sulfur content in the three fractions collected by coulometric method. The volumes of the collected 275-325 and 325-350°C fractions are 226ml and 326ml respectively, and their sulfur contents are 5.27g / l, 21.04g / l, and 18.36g / l respectively. Put the collected fractions at 275~350℃ in a 1000ml four-neck flask, mix well, and at the same time add dropwise hydrogen peroxide with 1 times the sulfur content of petroleum and 1ml of MnSO with a concentration of 2%. 4 solution, the dropping speed is 1.5 drops / second, the reaction temperature is 20±2°C, and the stirring rate is 300 rpm. After the dropwise addition, the stirring reaction was continued for 1 hour, the layers were separated, and the brown liquid in the upper layer was collected to obtain crude petroleum sulfoxide. Add ben...

Embodiment 2

[0024] Put the collected fraction at 275~350°C in a 1000ml four-necked flask, mix well, and at the same time add 1.2 times the sulfur content of petroleum hydrogen peroxide and 2ml of 2% MnSO 4 solution, the dropping speed is 1.5 drops / second, the reaction temperature is 20±2°C, and the stirring rate is 300 rpm. After the dropwise addition, the stirring reaction was continued for 1 hour, the layers were separated, and the brown liquid in the upper layer was collected to obtain crude petroleum sulfoxide. Add benzenesulfonic acid to the crude product of petroleum sulfoxide at a ratio of 1:0.8, mix well, let stand to separate layers, and take the lower layer of liquid. Add cyclohexane into the above-mentioned lower layer liquid at a ratio of 1:0.8, mix evenly, let it stand for stratification, take the upper layer liquid, wash it three times with deionized water, collect the benzene extract phase and carry out vacuum distillation on it, and distill out the cyclohexane Hexane to o...

Embodiment 3

[0026] Put the collected fraction at 275~350°C in a 1000ml four-necked flask, mix well, and at the same time add 1.3 times the sulfur content of petroleum hydrogen peroxide and 3ml of 2% MnSO 4 solution, the dropping speed is 1.5 drops / second, the reaction temperature is 20±2°C, and the stirring rate is 300 rpm. After the dropwise addition, the stirring reaction was continued for 1 hour, the layers were separated, and the brown liquid in the upper layer was collected to obtain crude petroleum sulfoxide. Add benzenesulfonic acid to the crude product of petroleum sulfoxide at a ratio of 1:1.2, mix well, let stand to separate layers, and take the lower layer of liquid. Add cyclohexane to the above-mentioned lower layer liquid in a ratio of 1:1.2, mix well, let stand to separate layers, take the upper layer liquid, wash it three times with deionized water, collect the benzene extract phase and carry out vacuum distillation to it, and distill out the cyclohexane Hexane to obtain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com