A kind of preparation method of cuboid lithium battery cathode material iron manganese phosphate lithium

A lithium iron manganese phosphate, cuboid-shaped technology, which is applied in the field of new energy material preparation, can solve the problems of long cycle, poor electrochemical performance of synthetic products, and high energy consumption, and achieves low cost, improved ionic conductivity, and enhanced electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

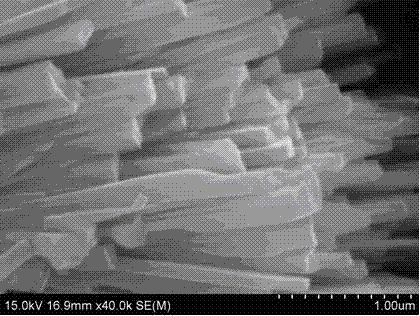

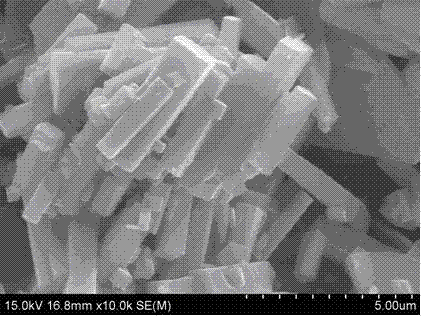

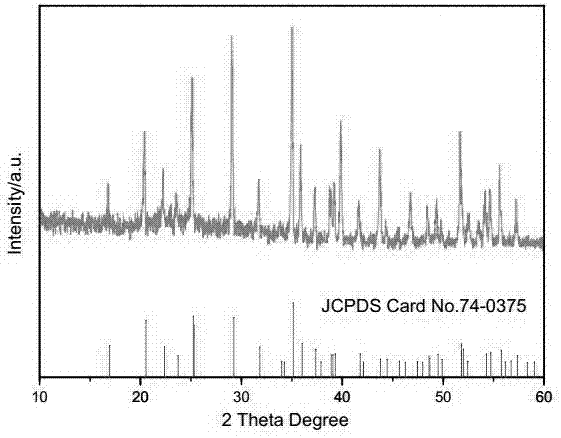

[0032] Embodiment 1: A preparation method of lithium iron manganese phosphate cathode material for a cuboid lithium battery, comprising the following steps: dissolving 2.0402 g of lithium acetate in 20 ml of water, dissolving 2.7043 g of manganese sulfate in 20 ml of water, dissolving 1.5686 g of sulfuric acid Add ferrous ammonium into the manganese sulfate solution, stir until dissolved, pass inert gas protection during the process of dissolving and stirring and mixing, put 2.3006g of ammonium dihydrogen phosphate solution in 20nl water, mix lithium salt solution, phosphorus source solution and manganese source, Mix the iron source mixed solution evenly.

[0033]Dissolve 0.5g of CTAB in 15ml of water, add 5ml of ethylene glycol, then add the CTAB solution to the mixing system, adjust the pH value to 8.5 with ammonia water, transfer the mixed solution to the reaction kettle, and react at 180°C 8h, after the reaction was completed, the precipitate was centrifuged and washed, dr...

Embodiment 2

[0036] Embodiment 2: A preparation method of lithium iron manganese phosphate cathode material for a cuboid lithium battery, comprising the following steps:

[0037] Dissolve 2.0402g of lithium acetate in 20ml of water, 2.7043g of manganese sulfate in 20ml of water, add 1.5686g of ferrous ammonium sulfate into the manganese sulfate solution, stir until dissolved, and pass inert gas during the process of dissolving and stirring For protection, mix 2.3006g of ammonium dihydrogen phosphate solution in 20nl water, lithium salt solution, phosphorus source solution, manganese source and iron source mixed solution evenly. Dissolve 0.5g of EDTA in 15ml of water, and add 5ml of ethylene glycol, then add the EDTA solution to the mixing system, adjust the pH value to 8.5 with ammonia water, transfer the mixed solution to the reaction kettle, and react at 170°C 10h, after the reaction was completed, the precipitate was centrifuged and washed, dried, and then the intermediate product was m...

Embodiment 3

[0039] Embodiment 3: A preparation method of lithium iron manganese phosphate cathode material for a cuboid lithium battery, comprising the following steps:

[0040] Dissolve 2.0402g of lithium acetate in 20ml of water, 2.7043g of manganese sulfate in 20ml of water, add 1.5686g of ferrous ammonium sulfate into the manganese sulfate solution, stir until dissolved, and pass inert gas during the process of dissolving and stirring For protection, mix 2.3006g of ammonium dihydrogen phosphate solution in 20nl water, lithium salt solution, phosphorus source solution, manganese source and iron source mixed solution evenly. Dissolve 0.5g of CTAB in 15ml of water, add 5ml of ethylene glycol, then add the CTAB solution to the mixing system, adjust the pH value to 8.5 with ammonia water, transfer the mixed solution to the reaction kettle, and react at 150°C After 12 hours of reaction, the precipitate was centrifuged and washed, dried, and then the intermediate product was mixed with 0.750...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com