Method for preparing spherical nanometer zirconium silicate powder

A technology of zirconium silicate and nano-zirconia, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of many processing procedures, low bonding strength, and affecting performance, and achieve a smooth and dense surface. Simple, growth-slowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

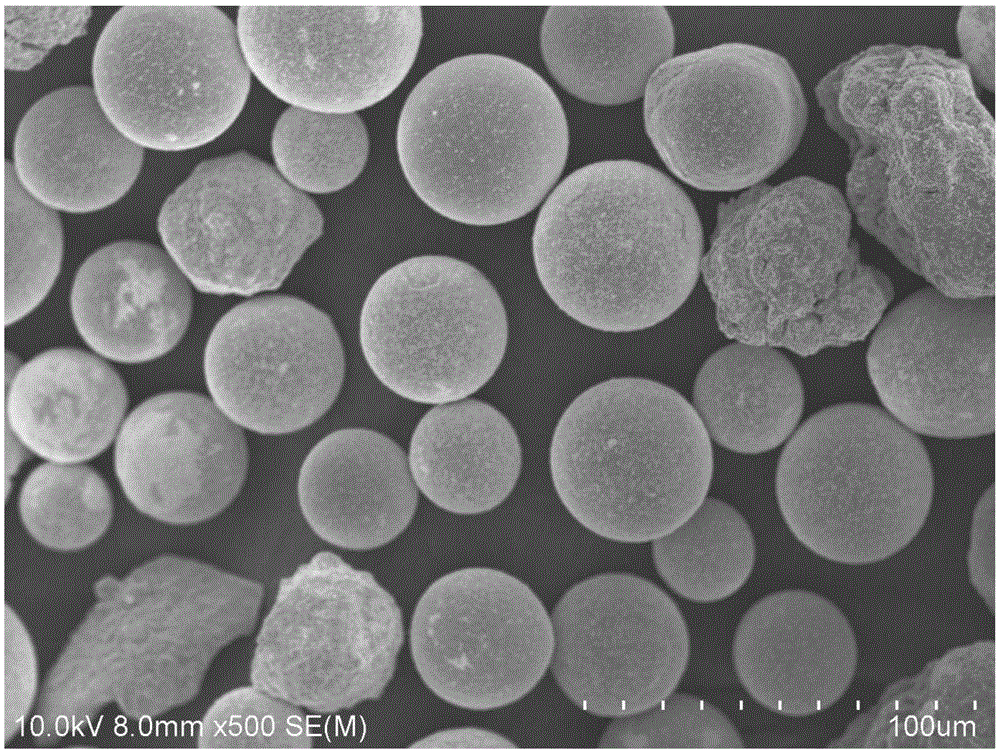

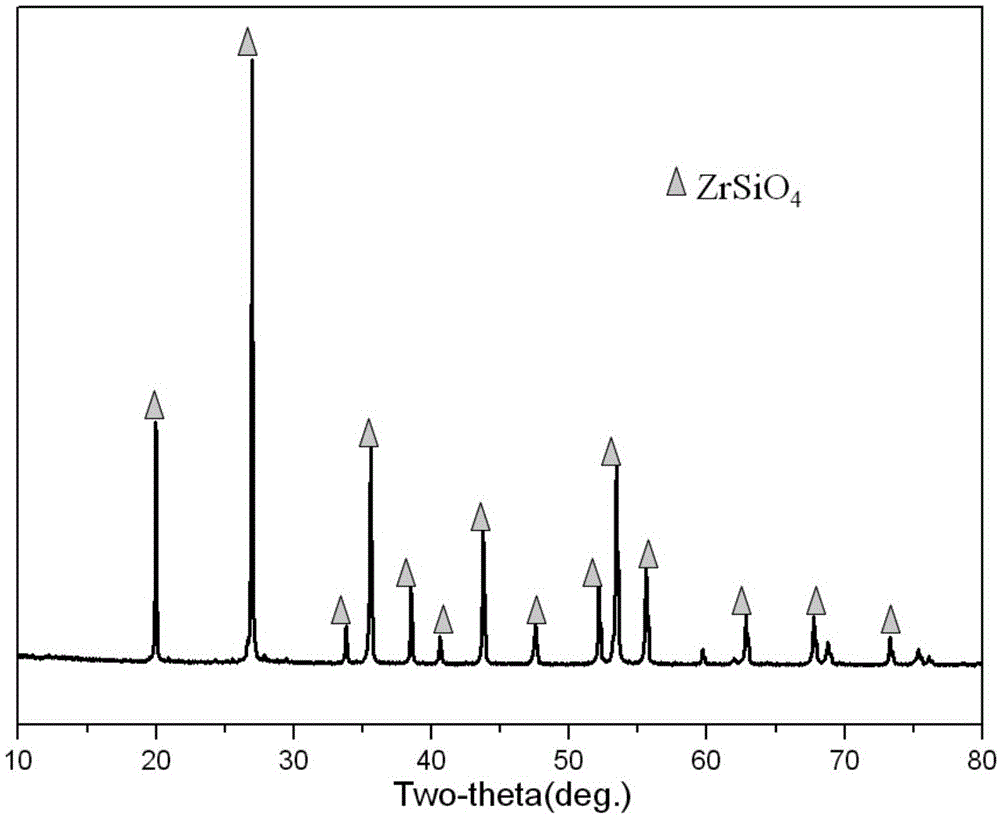

[0047] A preparation method of spherical nano zirconium silicate powder, the method steps are as follows:

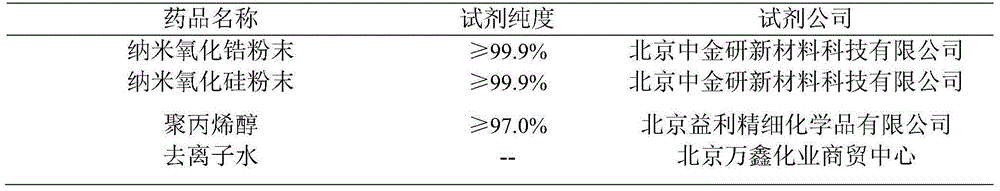

[0048] (1) Mix 738g of nano-zirconia powder and 360g of nano-silicon oxide powder evenly to obtain mixed powder a; add mixed powder a, 1548.18g of deionized water and 109.8g of polyvinyl alcohol solution with a mass fraction of 10wt% into the vertical ball mill In, mix uniformly, obtain the slurry 1 that solid content is 40wt%;

[0049] Wherein, the nano-zirconia powder and the nano-silicon oxide powder have a particle size of 10-100 nm;

[0050] Described mixing adopts vertical ball mill, and ball milling parameter is as follows:

[0051] The ball-to-material ratio is 4:1; the rotational speed is 300rpm; the ball milling media are zirconia balls with a particle size of 10mm and 5mm respectively, and the mass ratio of the zirconia balls with a particle size of 10mm to the zirconia balls with a particle size of 10mm is 1:1 ;

[0052] (2) Add slurry 1 to the spray dryin...

Embodiment 2

[0059] A preparation method of spherical nano zirconium silicate powder, the method steps are as follows:

[0060] (1) Mix 738g of nano-zirconia powder and 360g of nano-silicon oxide powder evenly to obtain mixed powder a; add mixed powder a, 1048.59g of deionized water and 54.9g of polyvinyl alcohol solution with a mass fraction of 10wt% into the vertical ball mill In, mix evenly, obtain the slurry 1 that solid content is 50wt%;

[0061] Wherein, the nano-zirconia powder and the nano-silicon oxide powder have a particle size of 10-100 nm;

[0062] Described mixing adopts vertical ball mill, and ball milling parameter is as follows:

[0063] The ball-to-material ratio is 3:1; the rotational speed is 250rpm; the ball milling media are zirconia balls with particle diameters of 10mm and 5mm respectively, and the mass ratio of the zirconia balls with a particle size of 10mm to the zirconia balls with a particle size of 10mm is 1:1 ;

[0064] (2) Add the slurry 1 to the spray dr...

Embodiment 3

[0070] A preparation method of spherical nano zirconium silicate powder, the method steps are as follows:

[0071] (1) Mix 738g nano-zirconia powder and 360g nano-silicon oxide powder evenly to obtain mixed powder a; add mixed powder a, 543.36g deionized water and 10wt% polyvinyl alcohol solution 219.6g into vertical ball mill In, mix evenly, obtain the slurry 1 that solid content is 60wt%;

[0072] Wherein, the nano-zirconia powder and the nano-silicon oxide powder have a particle size of 10-100 nm;

[0073] Described mixing adopts vertical ball mill, and ball milling parameter is as follows:

[0074] The ball-to-material ratio is 2:1; the rotational speed is 350rpm; the ball milling media are zirconia balls with a particle size of 10mm and 5mm respectively, and the mass ratio of the zirconia balls with a particle size of 10mm to zirconia balls with a particle size of 10mm is 1:1 ;

[0075] (2) Add slurry 1 to the spray drying tower, set the inlet temperature of the spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com