Method for quickly and efficiently degrading high-concentration unsym-dimethylhydrazine wastewater

An unbalanced dimethylhydrazine, high-concentration technology, applied in chemical instruments and methods, water pollutants, oxidized water/sewage treatment, etc. Improve utilization efficiency, improve treatment effect, and reduce the effect of adding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

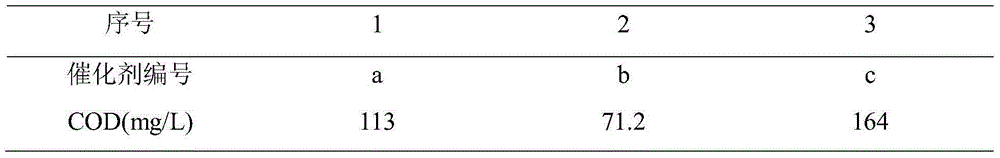

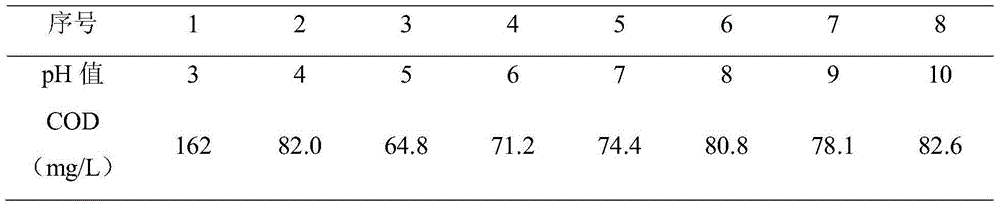

Embodiment 1

[0021] Weigh 35g of tetraethyl orthosilicate (TEOS), 70g of absolute ethanol, and 140g of deionized water to make a mixed solution, the mass ratio of TEOS: absolute ethanol: deionized water is 1:2:4, and weigh 0.218g of Add the ferrous acetate solid into the mixed solution and stir to dissolve, add dilute nitric acid to adjust the pH to 3, add a small amount of diethanolamine to the above solution to condense and reflux, then put the obtained product into an oven, dry the water to form a gel, and dry the gel Put it into a muffle furnace and calcinate at 300°C for 3h to obtain nano-iron-based SiO 2 , the nano-iron-based SiO 2 Grind to obtain a powdery solid, weigh 0.22g rhodium acetate, add it to absolute ethanol, dissolve it and immerse it in nano-iron-based SiO 2 Stir in the powder solid to form a suspension, stir and impregnate for 10 hours, so that Rh is wrapped on the surface of Fe, put it into a muffle furnace after drying, and calcinate at 300 ° C for 3 hours to obtain ...

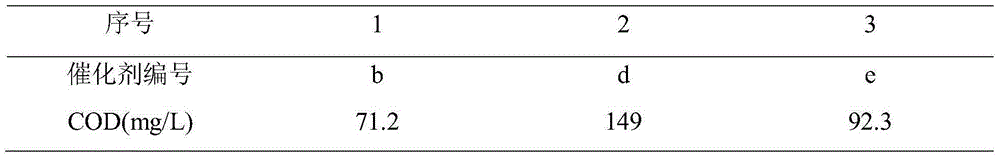

Embodiment 2

[0023] Weigh 35g of tetraethyl orthosilicate (TEOS), 105g of absolute ethanol, and 210g of deionized water to make a mixed solution, the mass ratio of TEOS: absolute ethanol: deionized water is 1:3:6, and weigh 0.544g of Add the ferrous acetate solid into the mixed solution and stir to dissolve, add dilute nitric acid to adjust the pH to 3, add a small amount of diethanolamine to the above solution to condense and reflux, then put the obtained product into an oven, dry the water to form a gel, and dry the gel Put it into a muffle furnace and calcinate at 350°C for 4h to obtain nano-iron-based SiO 2 , the nano-iron-based SiO 2 Grind to obtain a powdery solid, weigh 0.55g rhodium acetate, add it to absolute ethanol, dissolve it and immerse it in nano-iron-based SiO 2 Stir in the powder solid to form a suspension, stir and impregnate for 10 hours, so that Rh is wrapped on the surface of Fe, put it into a muffle furnace after drying, and calcinate at 350 ° C for 4 hours to obtain...

Embodiment 3

[0025]Weigh 35g of tetraethyl orthosilicate (TEOS), 140g of absolute ethanol, and 280g of deionized water to make a mixed solution, the mass ratio of TEOS: absolute ethanol: deionized water is 1:4:8, and weigh 1.088g of Add the ferrous acetate solid into the mixed solution and stir to dissolve, add dilute nitric acid to adjust the pH to 3, add a small amount of diethanolamine to the above solution to condense and reflux, then put the obtained product into an oven, dry the water to form a gel, and dry the gel Put it into a muffle furnace and calcinate at 410°C for 6h to obtain nano-iron-based SiO 2 , the nano-iron-based SiO 2 Grind to obtain a powdery solid, weigh 1.1g rhodium acetate, add it to absolute ethanol, dissolve it and immerse it in nano-iron-based SiO 2 Stir in the powder solid to form a suspension, stir and impregnate for 10 hours, so that Rh is wrapped on the surface of Fe, put it into a muffle furnace after drying, and calcinate at 410 ° C for 6 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com