Method for separating and purifying 2,6-dimethoxy phenol and acetosyringone from biological oil

A technology of dimethoxyphenol and acetosyringone, which is applied in the field of separation and purification of bio-based chemicals, can solve the problems of complex bio-oil components and difficult to obtain pure industrial chemicals, and achieves improved utilization value, low cost and cumbersome process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

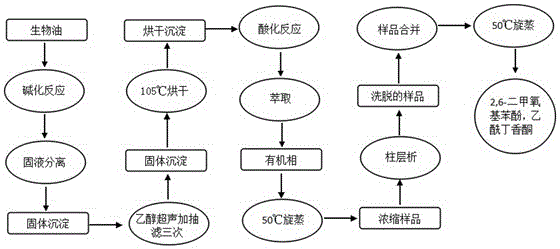

Method used

Image

Examples

Embodiment 1

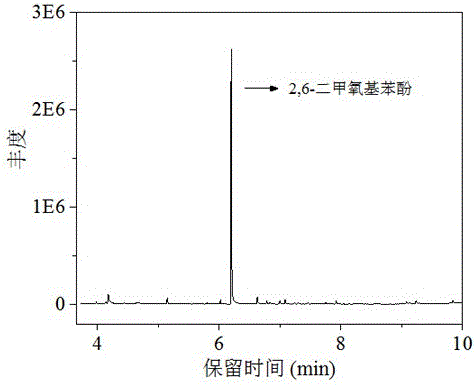

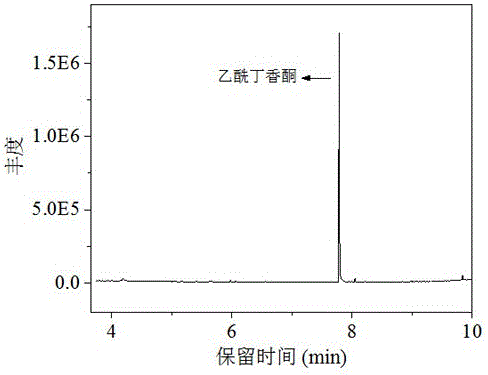

[0036]Add 1.31g of solid calcium oxide into 10mL of water to react to form a mixed solution of calcium hydroxide. Stir it evenly and add 1.0g of bio-oil produced after hydrothermal liquefaction of rice straw. The shaking reaction temperature is 50°C, and the reaction time is 20min. After the completion, the solid precipitate was separated by suction filtration. After the solid precipitate was subjected to ultrasonic suction filtration with ethanol three times, it was placed in an oven for 4 hours at 105°C, and 0.05 g of the obtained solid precipitate was added to 10 mL of hydrochloric acid with a concentration of 4 mol / L for 20 min. The reaction solution from the previous step was extracted three times with dichloromethane, mixed and shaken, and allowed to stand for 1 h to form a distinct organic phase and an aqueous phase. Take the organic phase from the previous step and remove dichloromethane by rotary evaporation at 50°C, dissolve the sample obtained by rotary evaporation w...

Embodiment 2

[0038] Add 1.56g of solid magnesium hydroxide into 10mL of water to form a mixed solution. Stir it evenly and add 1.0g of bio-oil produced after hydrothermal liquefaction of Salix salix. The shaking reaction temperature is 70°C and the reaction time is 20min. The solid precipitate was separated by filtration. After the solid precipitate was ultrasonically filtered three times with ethanol, it was baked in an oven at 105°C for 4 hours. 0.05 g of the obtained solid precipitate was added to 10 mL of 10 mol / L hydrochloric acid for ultrasonic reaction for 20 min. The reaction solution from the previous step was extracted three times with dichloromethane, mixed and shaken, and allowed to stand for 1 h to form a distinct organic phase and an aqueous phase. Take the organic phase from the previous step and remove dichloromethane by rotary evaporation at 50°C, dissolve the sample obtained by rotary evaporation with 2 mL of ethyl acetate, and add it as the original sample to the top laye...

Embodiment 3

[0040] Add 4.62g of solid barium oxide into 10mL boiling water to react to form barium hydroxide suspension, stir it evenly, add 1.0g of bio-oil produced after hydrothermal liquefaction of water hyacinth, shake the reaction temperature at 60°C, and the reaction time is After 20 minutes, after the reaction was completed, the solid precipitate was separated by suction filtration. After the solid precipitate was ultrasonically filtered three times with ethanol, it was placed in an oven at 105°C for 4 hours, and 0.05 g of the obtained solid precipitate was added to 10 mL of hydrochloric acid with a concentration of 8 mol / L for ultrasonic reaction. 20min. The reaction solution from the previous step was extracted three times with dichloromethane, mixed and shaken, and allowed to stand for 1 h to form a distinct organic phase and an aqueous phase. Take the organic phase from the previous step and remove dichloromethane by rotary evaporation at 50°C, dissolve the sample obtained by r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com