High-density cement slurry suitable for shale gas cementing and preparation method of high-density cement slurry

A high-density, cement slurry technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that the mechanical properties of cement stone cannot meet the requirements, the sealing quality of the second interface is difficult to guarantee, and the casing in the horizontal section is centered To improve the flexural strength and impact resistance, reduce the modulus of elasticity, and improve the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

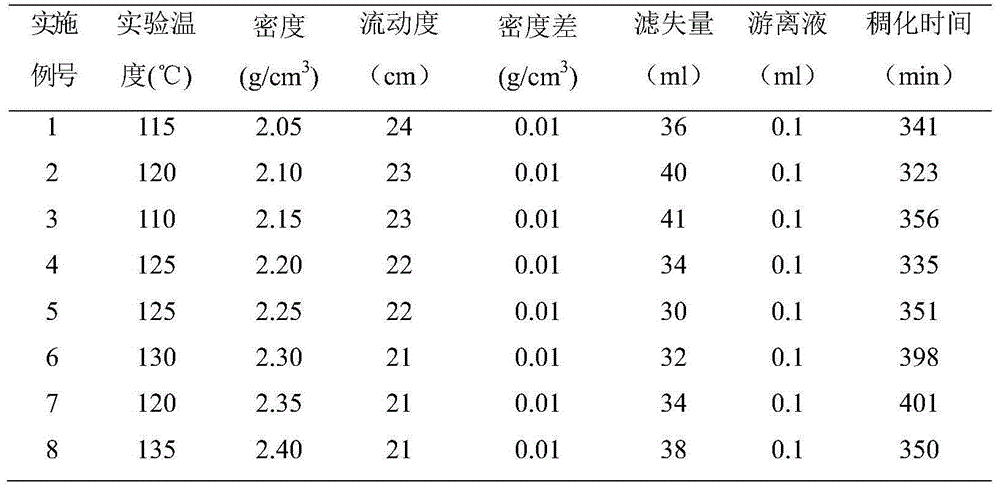

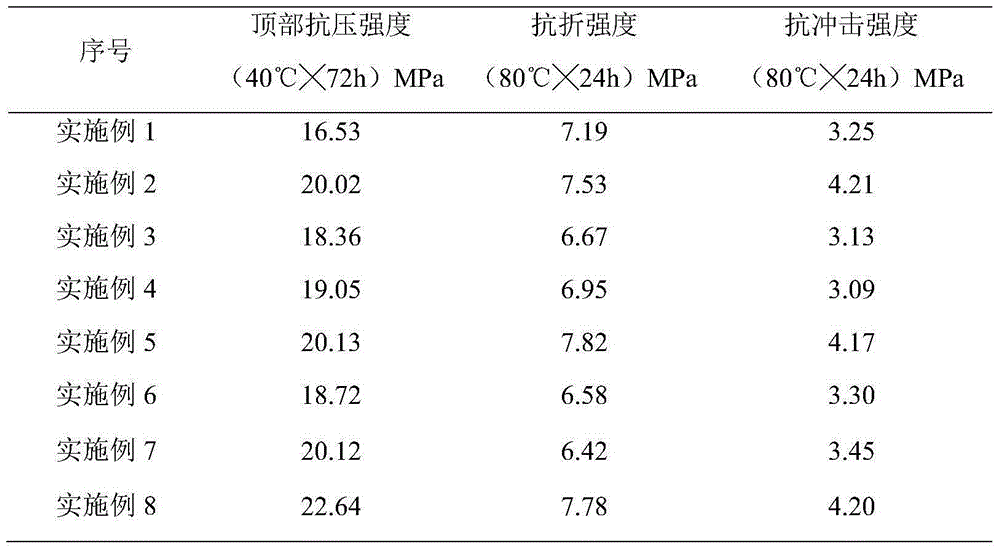

Examples

Embodiment 1

[0018] [Example 1] A high-density cement slurry suitable for shale gas well cementing is prepared from the following raw materials in parts by weight: 100 parts of cement, 15 parts of weighting agent, 30 parts of high-temperature strength stabilizer, and 10 parts of filler 5 parts, 5 parts of elastoplastic agent, 45 parts of fresh water, 7 parts of water loss reducer, 1 part of retarder, 0.5 part of dispersant, 0.2 part of defoamer; the weighting agent is iron ore powder, and iron ore powder is 120 mesh; the weighting stabilizer is manganese ore powder, and the particle size of manganese ore powder is 300 mesh; the high temperature strength stabilizer is active silicon powder, and the particle size of active silicon powder is 80 mesh; the retarder is Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer; the dispersant is aldehyde-ketone condensate or naphthalene-based dispersant; The fibers and mica sheets are made of toughening materials; the defoamer is a polyeth...

Embodiment 2

[0022] [Example 2] A high-density cement slurry suitable for shale gas well cementing is prepared from the following raw materials in parts by weight: 100 parts of cement, 15 parts of weighting agent, 10 parts of weighting stabilizer, high temperature strength stabilizer 30 parts, 15 parts of filler, 3 parts of elastoplastic agent, 44 parts of fresh water, 6 parts of fluid loss reducer, 1 part of retarder, 1 part of dispersant, 0.2 part of defoamer; the weighting agent is iron ore Powder, iron ore powder is 130 mesh; described aggravating stabilizer is manganese ore powder, and the particle diameter of manganese ore powder is 350 mesh; Described high temperature strength stabilizer is active silicon powder, and the particle diameter of active silicon powder is 100 mesh; The retarder is acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer; the dispersant is aldehyde-ketone condensate or naphthalene-based dispersant; Powder is the main ingredient, short fibers and mi...

Embodiment 3

[0026] [Example 3] A high-density cement slurry suitable for shale gas well cementing is prepared from the following raw materials in parts by weight: 100 parts of cement, 30 parts of weighting agent, 10 parts of weighting stabilizer, high temperature strength stabilizer 30 parts, 11 parts of filler, 5 parts of elastoplastic agent, 44 parts of fresh water, 6 parts of water loss reducer, 1.2 parts of retarder, 1.5 parts of dispersant, 0.3 part of defoamer; the weighting agent is iron ore Powder, iron ore powder is 150 mesh; described aggravating stabilizer is manganese ore powder, and the particle diameter of manganese ore powder is 400 mesh; Described high temperature strength stabilizer is active silicon powder, and the particle diameter of active silicon powder is 150 mesh; The retarder is acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer; the dispersant is aldehyde-ketone condensate or naphthalene-based dispersant; Powder is the main ingredient, and short fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com