Silicon-based nitrogen oxide LED (light-emitting diode) fluorescent powder and preparation method therefor

A nitrogen oxide and phosphor technology, which is applied in the field of rare earth luminescent materials, can solve the problems of high production cost and complicated preparation process of nitride phosphors, and achieves easy operation, good luminous intensity and anti-aging performance, and improved luminous performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

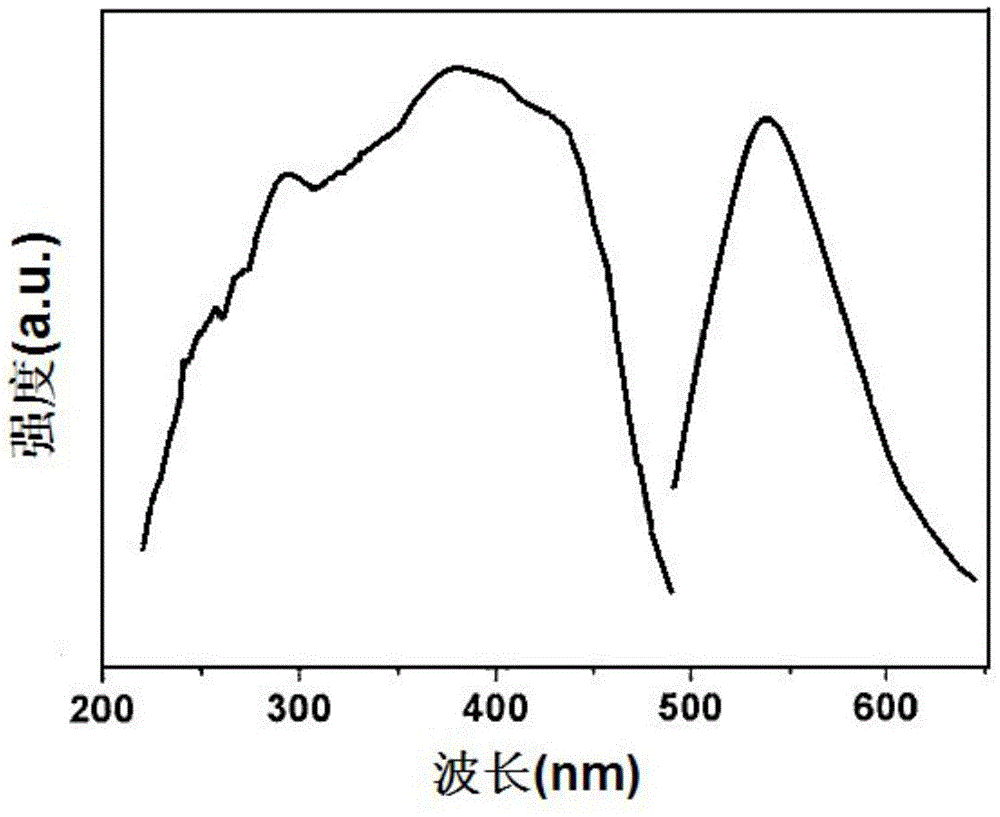

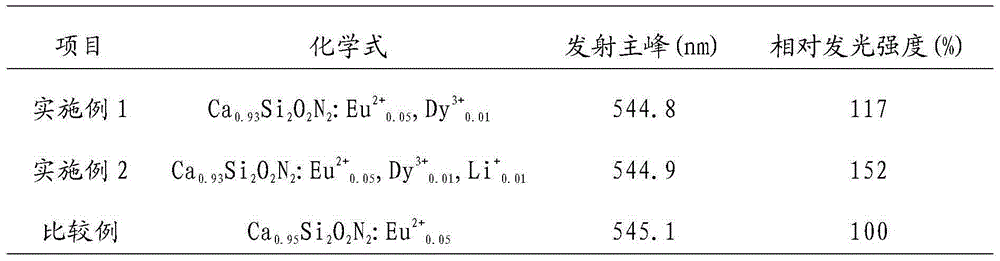

[0029] (1) According to the chemical composition Ca 0.94 Si 2 o 2 N 2 :Eu 2+ 0.05 , Dy 3+ 0.01 The metering ratio weighs the following raw materials: Ca(NO 3 ) 2 , Eu(NO 3 ) 3 , Dy(NO 3 ) 3 and silicon nitride powder, the Ca(NO 3 ) 2 , Eu(NO 3 ) 3 and Dy(NO 3 ) 3Place in deionized water, stir and mix evenly to obtain the first solution with a concentration of 0.2-0.5mol / L, heat the above-mentioned first solution with a 60°C water bath; take high-purity silicon nitride powder, add it to deionized water for ultrasonic dispersion for 5 minutes Finally, pour it into the first solution to obtain the second suspension, and keep stirring at a rotating speed of 300r / min; then add the precipitant oxalic acid crystals to the second suspension, coprecipitate to generate a large amount of white product, and raise the temperature of the water bath To 85°C, keep warm for 2 hours, filter with suction, dry in a blast oven at 100°C for 8 hours, grind, and pass through a 200-m...

Embodiment 2

[0035] (1) According to the chemical composition Ca 0.93 Si 2 o 2 N 2 :Eu 2+ 0.05 , Dy 3+ 0.01 , Li + 0.01 The metering ratio weighs the following raw materials: Ca(NO 3 ) 2 , Eu(NO 3 ) 3 , Dy(NO 3 ) 3 、LiNO 3 and silicon nitride powder, the Ca(NO 3 ) 2 , Eu(NO 3 ) 3 , Dy(NO 3 ) 3 and LiNO 3 Place in deionized water, stir and mix evenly to obtain the first solution with a concentration of 0.2-0.5mol / L, heat the above-mentioned first solution with a 60°C water bath; take high-purity silicon nitride powder, add it to deionized water for ultrasonic dispersion for 5 minutes Finally, pour it into the first solution to obtain the second suspension, and keep stirring at a rotating speed of 300r / min; then add the precipitant oxalic acid crystals to the second suspension, coprecipitate to generate a large amount of white product, and raise the temperature of the water bath To 85°C, keep warm for 2 hours, filter with suction, dry in a blast oven at 100°C for 8 hour...

Embodiment 3

[0049] (1) According to the general chemical formula Sr 0.98 Si 2 o 2 N 2 :Eu 0.01 ,Tb 0.01 The metering ratio in weighs the following raw materials: Sr(NO 3 ) 2 , Eu(NO 3 ) 3 and Tb(NO 3 ) 3 , the Sr(NO 3 ) 2 and Eu(NO 3 ) 3 Place in deionized water, stir and mix evenly to obtain the first solution with a concentration of 0.2-0.5mol / L, heat the above-mentioned first solution with a 40°C water bath; take high-purity silicon nitride powder, add it to deionized water for ultrasonic dispersion for 5 minutes Finally, add it to the first solution to obtain the second suspension, keep stirring at a speed of 300r / min; then dissolve the precipitating agent urea in deionized water and add it to the second suspension, heat slowly and heat up, homogeneous Precipitation produces a large amount of white product, raise the temperature of the water bath to 80°C, keep it warm for 2 hours, filter it with suction, dry it in a blast drying oven at 100°C for 8 hours, grind it, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com