Fabrication method and structure of a semiconductor power device structure

A technology of power devices and semiconductors, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve problems affecting high-frequency performance of devices, long device shutdown time, etc., to improve device performance, improve breakdown voltage, Effect of Reducing On-Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

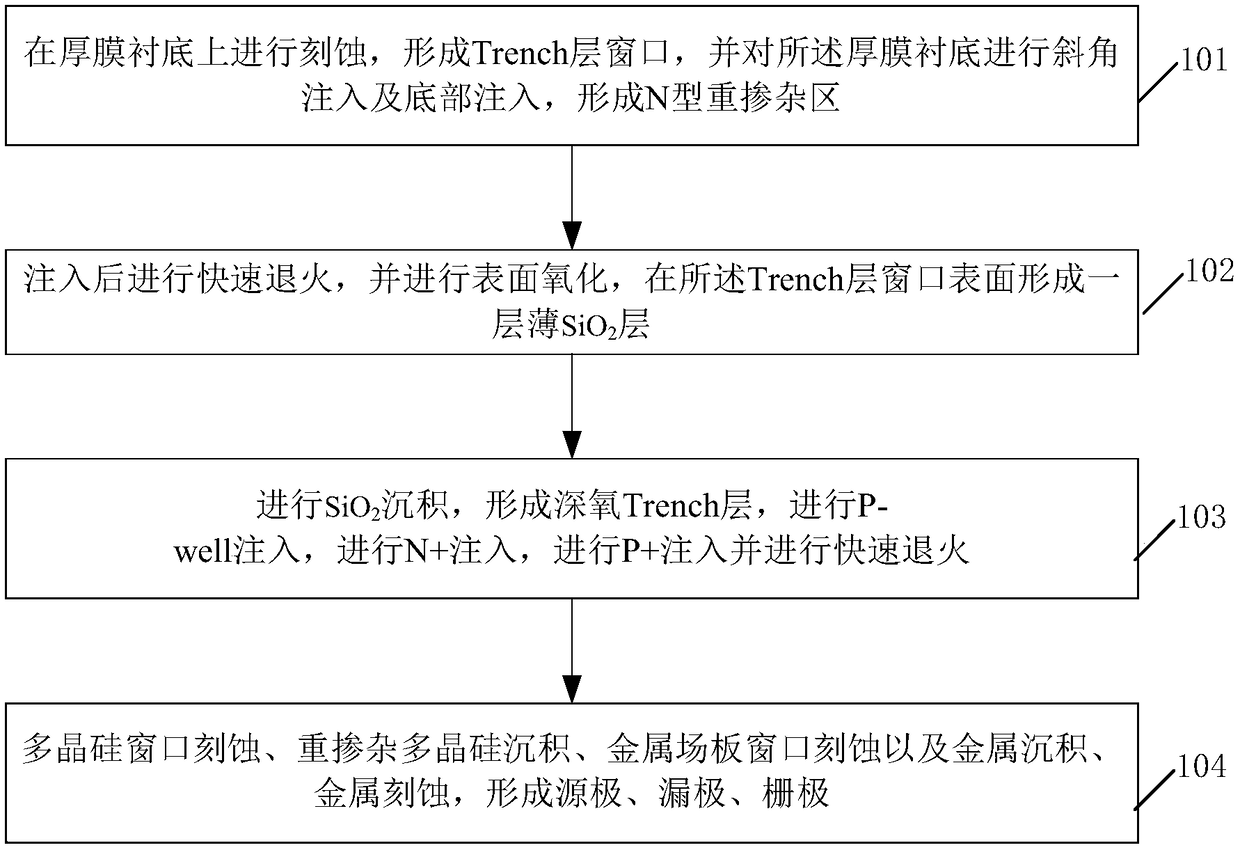

[0028] refer to figure 1 , figure 1 It is a schematic flow chart of a method for preparing a semiconductor power device structure according to an embodiment of the present invention.

[0029] In Embodiment 1, the preparation method of the semiconductor power device structure includes:

[0030] Step 101, performing etching on the thick film substrate to form a Trench layer window, and performing oblique angle implantation and bottom implantation on the thick film substrate to form an N-type heavily doped region;

[0031] Step 102, perform rapid annealing after implantation, and perform surface oxidation to form a thin layer of SiO on the surface of the Trench layer window 2 Floor;

[0032] Step 103, carry out SiO 2 Deposition, formation of deep oxygen trench layer, P-well implantation, N+ implantation, P+ implantation and rapid annealing;

[0033] Step 104, polysilicon window etching, heavily doped polysilicon deposition, metal field plate window etching, metal deposition,...

Embodiment 2

[0050] refer to figure 2 , figure 2 It is a schematic diagram of the structure of the semiconductor power device of the embodiment of the present invention.

[0051] In Embodiment 2, the semiconductor power device structure includes:

[0052] Source, source metal, gate metal, drain, drain metal, source body region, polysilicon, metal field plate, N-type heavily doped region, oxygen Trench layer, N-type drift region, buried oxide layer, P-type lining end;

[0053] The P-type substrate is on the bottom layer of the semiconductor power device structure, the buried oxide layer is on the P-type substrate, the N-type drift region is on the buried oxide layer, and the N-type The heavily doped region is above the N-type drift region, the oxygen Trench layer is above the N-type heavily doped region, and the metal field plate is a vertical field plate with multiple layers of different lengths. A heavily doped n-type layer is injected into the N-type drift region near the surface o...

Embodiment 3

[0058] refer to image 3 , image 3 It is another schematic diagram of the structure of the semiconductor power device of the embodiment of the present invention.

[0059] Figure 4 It is a schematic diagram of the electric field of a semiconductor power device according to an embodiment of the present invention.

[0060] Specifically, the breakdown voltage of the LDMOS structure of a lateral power device is determined by both the lateral withstand voltage and the vertical withstand voltage, and within a certain range, the lateral withstand voltage of the device is proportional to the length of the drift region and inversely proportional to the doping concentration of the drift region , while the on-resistance of the device is just the opposite. Therefore, there is a contradictory relationship between the breakdown voltage and the on-resistance of the lateral power device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com