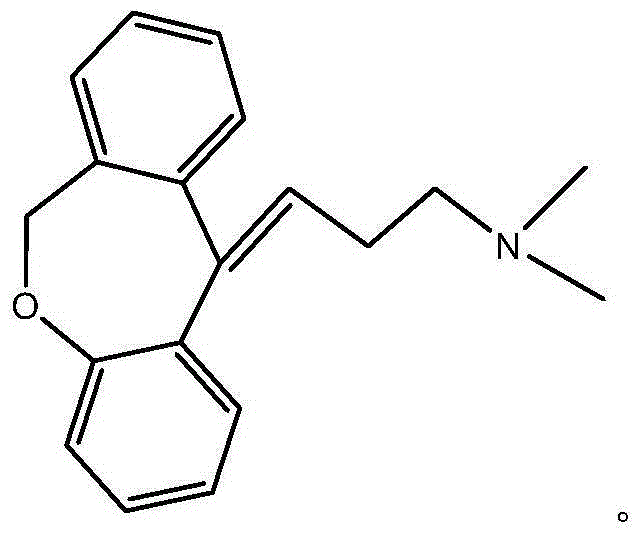

Method for synthesizing doxepin hydrochloride by taking halomethyl o-toluate as raw material

A technology of methyl ortho-halomethylbenzoate and doxepin hydrochloride, applied in the field of synthesizing doxepin hydrochloride, can solve problems such as low yield and low product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

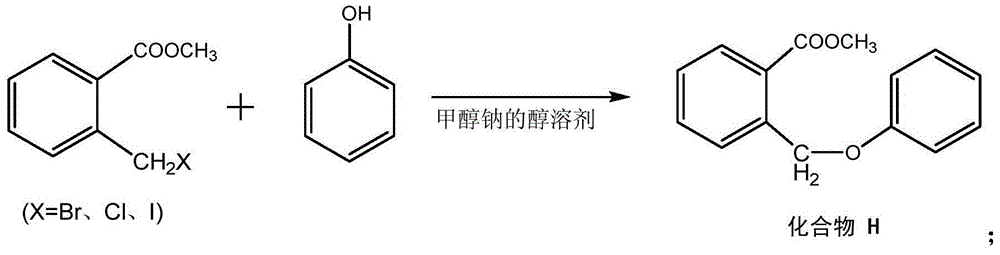

[0042] In the reaction vessel of 20L, put methyl o-bromomethylbenzoate, the ethanol solvent of sodium methylate that consumption is 3 (the total mass of methyl o-bromomethylbenzoate and phenol is 1 meter), adjust the temperature of reaction solution After reaching 50°C, start to drop phenol with a substance quantity of 1.05 (based on the substance quantity of methyl o-bromomethylbenzoate as 1), and the dropwise addition time is 1 h. After the dropwise addition was completed, after constant temperature reaction for 5 h, a known separation method was used to obtain methyl o-formate benzyl phenyl ether, which was named compound H.

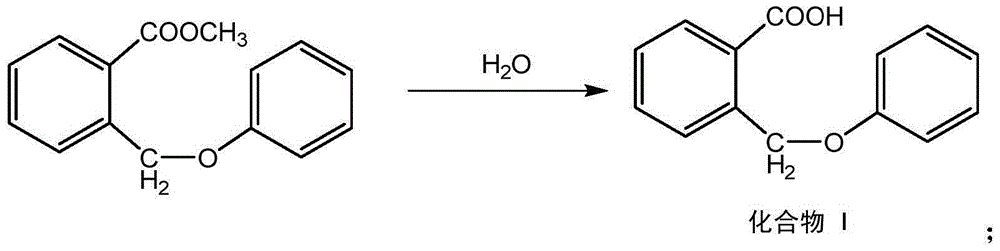

[0043] The above compound H and sodium hydroxide aqueous solution were placed in a reaction vessel, the temperature was adjusted at 30°C, the reaction was stirred for 8 hours, and (o-formyl)benzyl phenyl ether was separated by known separation means, which will be named as compound I.

[0044] The above compound I, the amount of acetyl chloride (calcu...

Embodiment 2

[0051] In the reaction vessel of 20L, put methyl o-bromomethylbenzoate, the ethanol solvent of sodium methylate that consumption is 10 (the total mass of methyl o-bromomethylbenzoate and phenol is 1 meter), adjust the temperature of reaction solution After reaching 60°C, start to drop phenol with a substance quantity of 1.15 (calculated that the substance quantity of methyl o-bromomethylbenzoate is 1), and the dropwise addition time is 1 h. After the dropwise addition was completed, after constant temperature reaction for 5 h, a known separation method was used to obtain methyl o-formate benzyl phenyl ether, which was named compound H.

[0052] Put the above-mentioned compound H and aqueous solution of sodium hydroxide into a reaction vessel, adjust the temperature at 40°C, stir the reaction for 4 hours, and obtain (o-formyl)benzylphenyl ether by using known separation methods, which will be named compound I.

[0053] Put the above-mentioned compound I, the acetyl chloride (ca...

Embodiment 3

[0060] In the reaction vessel of 20L, put methyl o-chloromethylbenzoate, the ethanol solvent of sodium methylate that consumption is 6 (the total mass of methyl o-bromomethylbenzoate and phenol is 1 meter), adjust the temperature of reaction solution After reaching 55°C, phenol with a substance quantity of 1.10 (calculated as 1 substance quantity of methyl o-bromomethylbenzoate) was started to be added dropwise, and the dropwise addition time was 1 h. After the dropwise addition was completed, after constant temperature reaction for 3.5 h, a known separation method was used to obtain methyl o-formate benzyl phenyl ether, which was named compound H.

[0061] The above-mentioned compound H and sodium hydroxide aqueous solution were placed in a reaction vessel, the temperature was adjusted at 35°C, the reaction was stirred for 6 hours, and (o-formyl)benzyl phenyl ether was separated by known separation means, which will be named compound I.

[0062] Put the above-mentioned compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com