Cerium oxide polishing solution and preparation method thereof

A technology of cerium oxide and polishing liquid, which is applied in the field of rare earth polishing liquid, can solve the problems of low polishing precision, poor dispersion and suspension performance, fast abrasive loss of polishing liquid, etc., and achieve the effect of high polishing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

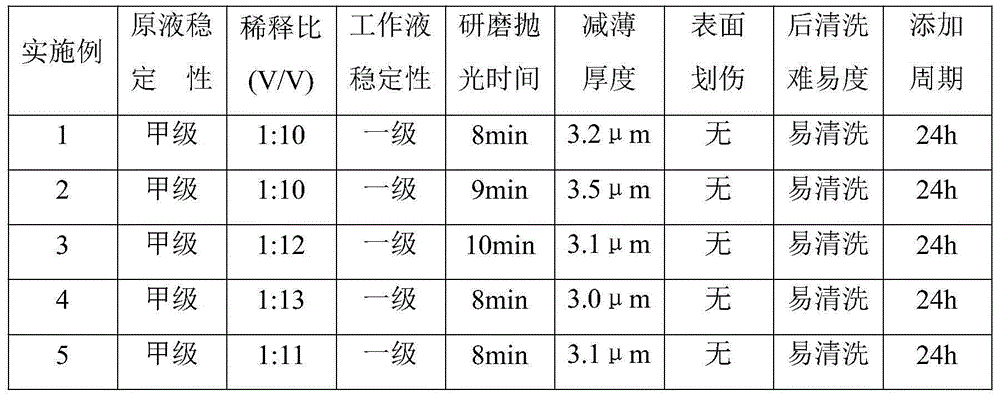

Examples

Embodiment 1

[0025] 0.2 parts of xanthan gum, 2 parts of sodium tripolyphosphate, 5 parts of sodium xylene sulfonate, 0.2 parts of EDTA-2Na, 4 parts of glycerin, 4002 parts of polyethylene glycol, 2 parts of magnesium aluminum silicate, 0.3 parts of thiourea , 3 parts of triethanolamine, 55 parts of cerium oxide polishing powder, and 26.3 parts of water.

Embodiment 2

[0027] 0.1 part of xanthan gum, 3 parts of sodium tripolyphosphate, 4 parts of sodium xylene sulfonate, 0.1 part of EDTA-2Na, 3 parts of glycerin, 4003 parts of polyethylene glycol, 1.5 parts of magnesium aluminum silicate, 0.1 part of thiourea , 2 parts of triethanolamine, 50 parts of cerium oxide polishing powder, and 33.2 parts of water.

Embodiment 3

[0029] 0.3 parts of xanthan gum, 1 part of sodium tripolyphosphate, 7 parts of sodium xylene sulfonate, 0.2 parts of EDTA-2Na, 7 parts of glycerin, 4002 parts of polyethylene glycol, 1 part of magnesium aluminum silicate, 0.2 parts of thiourea , 5 parts of triethanolamine, 51 parts of cerium oxide polishing powder, and 25.3 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com