Preparation method of monovalent ion selective composite film based on template method

An ion-selective, composite membrane technology, applied in the field of membrane separation, can solve the problems of poor stability and low flux, and achieve the effects of stable separation performance, simple operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

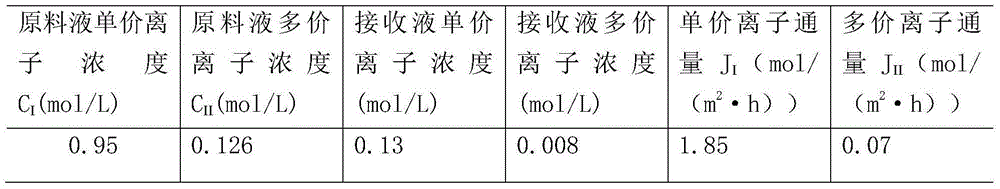

Embodiment 1

[0033] The polyacrylonitrile (PAN) flat ultrafiltration membrane with a molecular weight cut-off of 50,000 is used as the base membrane, polyethyleneimine (PEI) is the polycation, the polyanion used is polyacrylic acid (PAA), and nickel ions are used as template ions. The multivalent ion selective composite membrane is used to separate the concentrated seawater discharged after seawater desalination.

[0034] Assembly conditions and methods:

[0035] The first step is to prepare a 0.023mol / L nickel nitrate solution, and then prepare a 1g / L polyethyleneimine (PEI) solution with an equimolar concentration. Cationic electrolyte polyethylenimine (PEI) concentration is the chelating solution (solution A) of 0.8g / L, then the molar ratio of template nickel ion in this solution and amino group in polyethyleneimine (PEI) solution is 1:4 . Prepare a 0.8 g / L polyacrylic acid (PAA) solution for self-assembly.

[0036] In the second step, polyelectrolyte is deposited layer by layer self...

Embodiment 2

[0049] The polyacrylonitrile (PAN) flat ultrafiltration membrane with a molecular weight cut-off of 50,000 is used as the base membrane, polyethyleneimine is the polycation, the polyanion used is polyacrylic acid, and nickel ions are used as template ions to prepare mono-multivalent ion selective compounding. Membranes are used to separate concentrated seawater discharged after seawater desalination.

[0050] Assembly conditions and methods:

[0051] The first step is to prepare a 0.23mol / L nickel nitrate solution, and then prepare a 10g / L polyethyleneimine (PEI) solution with an equimolar concentration. Cationic electrolyte polyethyleneimine (PEI) concentration is the chelating solution (solution A) of 9.52g / L, then the molar ratio of template nickel ion in this solution and the amine group in polyethyleneimine (PEI) solution is 1:20 . Prepare 9.52g / L polyacrylic acid (PAA) solution for self-assembly.

[0052] In the second step, polyelectrolyte is deposited layer by layer...

Embodiment 3

[0063] The polyacrylonitrile (PAN) flat ultrafiltration membrane with a molecular weight cut-off of 50,000 is used as the base membrane, polyethyleneimine is the polycation, the polyanion used is polyacrylic acid, and nickel ions are used as template ions to prepare mono-multivalent ion selective compounding. Membranes are used to separate concentrated seawater discharged after seawater desalination.

[0064] Assembly conditions and methods:

[0065] The first step is to prepare a 0.069mol / L nickel nitrate solution, and then prepare a 3g / L polyethyleneimine (PEI) solution with an equimolar concentration. Cationic electrolyte polyethyleneimine (PEI) concentration is the chelating solution (solution A) of 2.85g / L, then the molar ratio of template nickel ion in this solution and the amine group in polyethyleneimine (PEI) solution is 1:20 . Prepare 2.85g / L polyacrylic acid (PAA) solution for self-assembly.

[0066] In the second step, polyelectrolyte is deposited layer by layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com