Method for low-temperature oxidation desulfurization of fuel oil

A technology for oxidative desulfurization and fuel oil, which is applied in the fields of oil processing, refining, and refining in the petrochemical industry. It can solve the problems of extraction agent regeneration-cycle, difficult synthesis of ionic liquids, and complex processes, etc., to overcome short catalyst life, The effect of avoiding large-scale equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

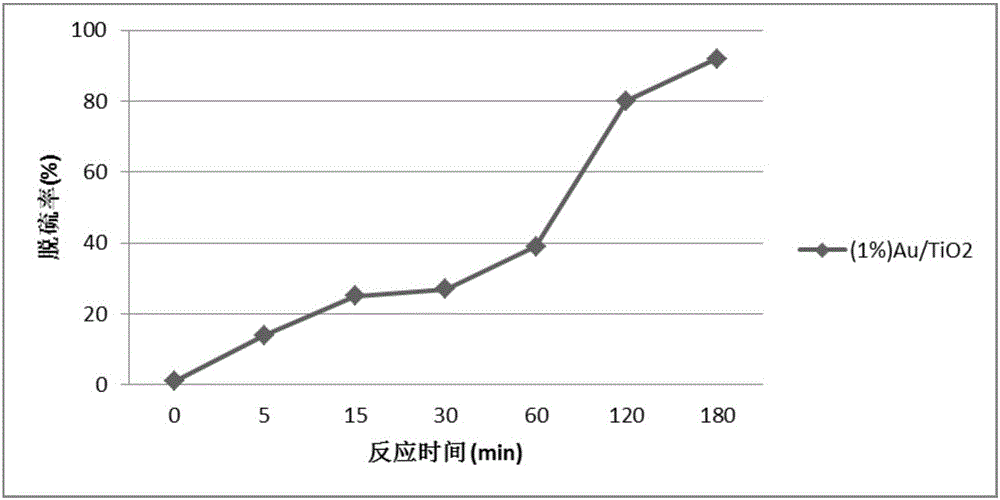

[0022] Using n-octane (CAS: 111-65-9, purity >96%, purchased from Aladdin reagents) and thiophene (1-thia-2,4-cyclopentadiene, CAS: 110-02-1, purity >99.5%, purchased from Aladdin Reagent) to configure simulated gasoline, and add decane (CAS: 124-18-5, purity >98%, purchased from Aladdin Reagent) as an internal standard for analysis. Add 1g of thiophene and 1g of decane to 998g of n-octane to configure simulated gasoline, in which the sulfur content is 61.45ppm.

[0023] Pipette simulated oil 100g, and Au(1%wt) / TiO 2 (AUROlite, CAS: 7440-57-5, Stremproduct) catalyst 2g, H 2 o 2 (CAS: 7722-84-1, purity > 30wt%, purchased from Sinopharm Chemical Reagent Co., Ltd.) 3.33g was added to a closed three-necked flask. Set the rotation speed to 700rpm by mechanical stirring, and react at 30°C for 180min, and take ~1g of sample during the reaction.

[0024] Agilent7890A type chromatography was used for analysis, and the chromatography was configured with 30mHP-5 capillary column, hyd...

Embodiment 2

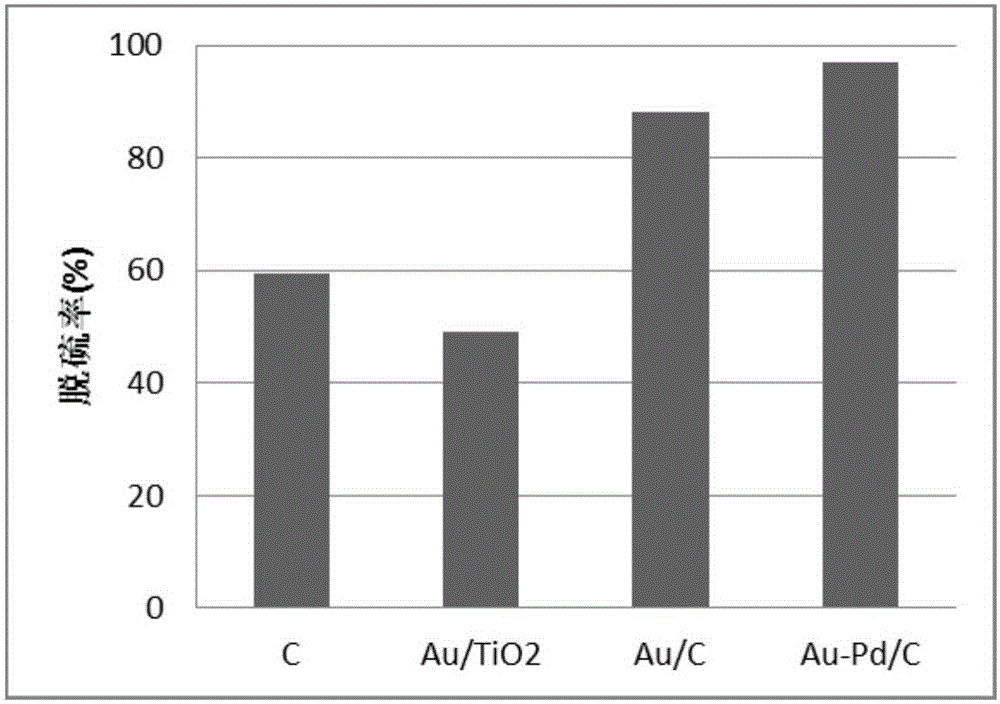

[0028] The configuration of the simulated oil is the same as in Example 1. Pipette simulated oil 100g, Au(1%wt) / TiO 2 (AUROlite, CAS:7440-57-5, Stremproduct), Au (1%wt) / C (self-made, prepared by modified ion exchange method), Au-Pd (1%wt) / C (self-made, prepared by sol deposition method) ) each catalyst 2g, H 2 o 2 (CAS: 7722-84-1, purity>30wt%, purchased from Sinopharm Chemical Reagent Co., Ltd.) 3.33g, the final pressure of oxygen was 30bar, the magnetic stirring was set at 700rpm, and the reaction was carried out at 60°C for 30min. Quantitative analysis of thiophene is the same as that described in Implementation 1. After 30min, C carrier, Au / TiO 2 , Au / C, Au-Pd / C desulfurization rates were 59.4%, 49.2%, 88.2% and 96.9%. Simulated gasoline treated with Au / C and Au-Pd / C can meet Euro V and China V standards.

Embodiment 3

[0030] The configuration of the simulated oil is the same as in Example 1. Pipette simulated oil 100g, and adopt Au(1wt%) / TiO prepared by impregnation method 2 (AUROlite, CAS: 7440-57-5, Stremproduct), Au (1wt%) / ZnO (AUROlite, CAS: 7440-57-5, Stremproduct), Au (1wt%) / C (self-made, modified ion exchange method Preparation) catalyst each 2g, H 2 o 2 (CAS: 7722-84-1, purity > 30wt%, purchased from Sinopharm Group Chemical Reagent Co., Ltd.) 3.33g, added together in a water-bath bottle with a sealed jacket, under the irradiation of a 300W high-pressure mercury lamp, using magnetic stirring, set Rotate at 700rpm, react at 60°C for 30min. The quantitative analysis of thiophene is the same as that shown in Implementation 1. After 30min, Au / TiO 2, Au / ZnO, Au / C desulfurization rates were 63.2%, 70.6% and 83.6%. Simulated gasoline treated with Au / C can meet Euro V and China V standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com