Wheat straw decomposition agent and method for preparing same

A technology for wheat straw and decomposing agent is applied in the field of wheat straw decomposing agent and its preparation, which can solve the problems of long fermentation period, incomplete decomposing, poor decomposition ability, etc., so as to improve decomposing efficiency, improve yield and quality, and be easy to cultivate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Wheat straw decomposing agent, including Bacillus subtilis, Trichoderma viride, Aspergillus niger, white rot fungus and Candida, among them, Bacillus subtilis≥0.6 billion cfu / g, Trichoderma viride≥0.5 billion cfu / g, Aspergillus niger≥ 040 million cfu / g, white rot fungus ≥ 060 million cfu / g, Candida ≥ 020 million cfu / g, the wheat straw decomposing agent is liquid.

Embodiment 2

[0039] The preparation method of the above-mentioned wheat straw decomposing agent comprises the following specific steps:

[0040] 1), preparation medium:

[0041] A. Preparation of LB liquid medium: Dissolve 10g of tryptone, 5g of yeast extract and 10g of NaCl in a 1L volumetric flask, adjust the pH value to 7.0-7.5 with 1M NaOH, dilute to 1L with water, and then pressurize at 121°C Sterilize for 20 minutes;

[0042] B, prepare LB solid medium: add agar in the LB liquid medium prepared in step A, the addition of agar is 15g / L;

[0043] C. Prepare PDA liquid culture medium: Dissolve 200g of potatoes and 20g of glucose in a 1L volumetric flask, dilute to 1L with water, and then autoclave at 121°C for 20min;

[0044] D, prepare PDA solid medium: add agar in the PDA liquid medium prepared in step C, the addition of agar is 15g / L;

[0045] E. Preparation of PDA liquid induction medium: Dissolve 200g of potatoes, 5g of glucose, and 15g of sodium carboxymethylcellulose in a 1L v...

Embodiment 3

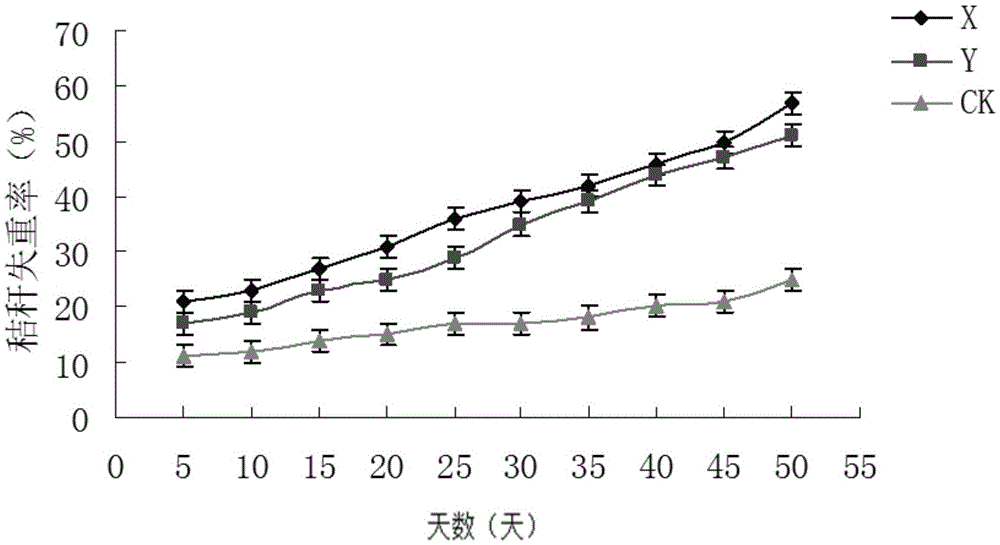

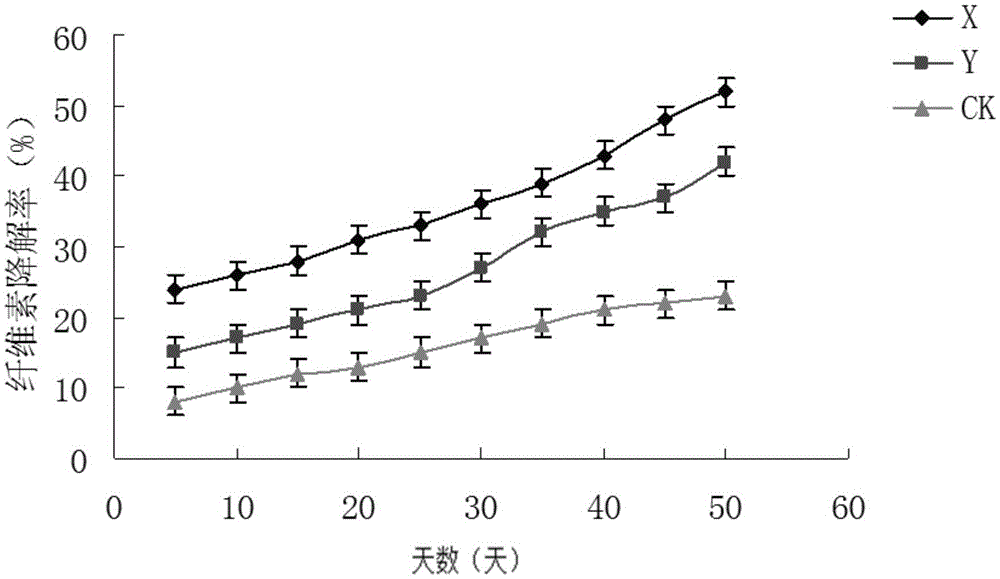

[0061] Analysis of the decomposing effect of the above-mentioned wheat straw decomposing agent:

[0062] Pile fresh wheat straw into a heap of 60 × 5 × 2m, carry out micro-spray watering on the wheat straw heap, continue to spray water for 3 days, stop watering when the moisture reaches 70wt%, and use the wheat straw decomposing agent prepared by the present invention according to 0.3wt% is diluted and sprayed into the wheat straw heap, and several bags of urea are evenly sprinkled to adjust the carbon-nitrogen ratio. The wheat straw heap is numbered (X).

[0063] In the same way, two wheat straw heaps of the same size were piled up as a control. One of the piles (Y) used the same quality of other brands of bacteria and urea of the same quality; the other pile (CK) was used as a control and only sprinkled The same quality of urea, no fungicide.

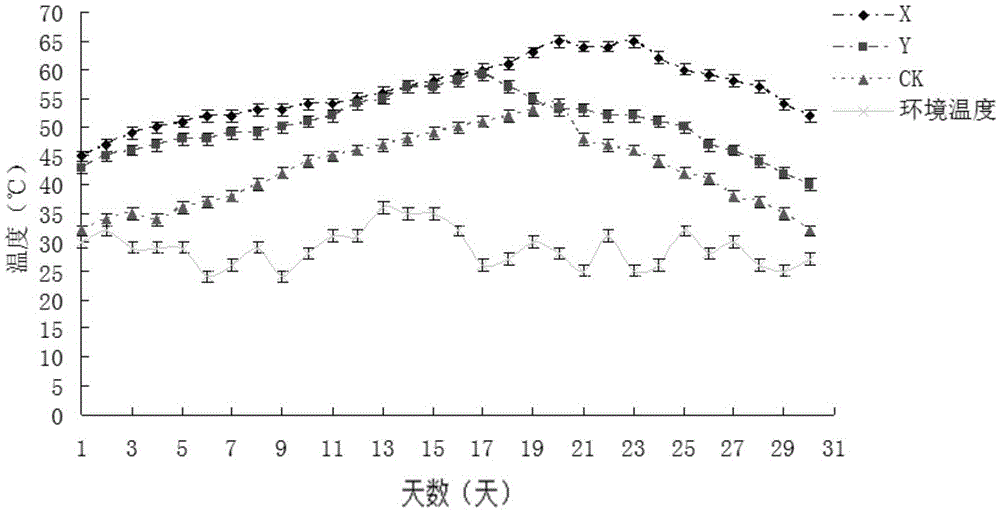

[0064] 1. Straw pile temperature

[0065] from figure 1 It can be seen that the temperature of the three piles (X, Y, CK) can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com