A kind of construction method and application of engineering strain for producing phenol by fermentation of glycerol

A technology of engineering strains and glycerin, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of high production cost of phenol, large environmental pollution, and many by-products, so as to reduce production costs and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

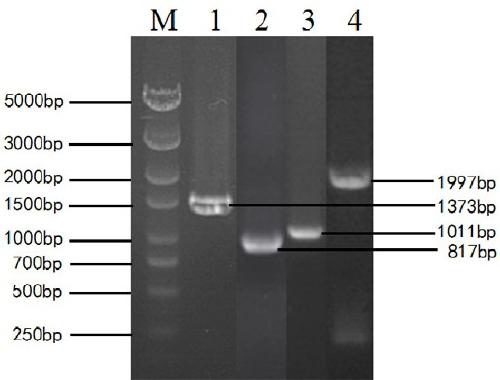

[0057] Example 1. Construction of recombinant E. coli used for glycerol fermentation to produce phenol

[0058] 1. Construction of recombinant expression vector pTrc99a-tpl-p4m

[0059] 1. Selection and optimization of tpl gene

[0060] Select the complete CDS sequence of tyrosine phenol lyase (tpl), and obtain an optimized tyrosine phenol lyase gene sequence suitable for expression in E. coli after design and repeated verification, that is, the wild-type tyrosine phenol lyase gene The sequence is transformed into an E. coli preferred (high frequency use) codon optimized sequence without changing the amino acid sequence, thereby increasing the expression level of tyrosine phenol lyase in E. coli culture environment.

[0061] The amino acid sequence of the tyrosine phenol lyase is specifically shown in sequence 1 in the sequence table, and consists of 456 amino acids in total;

[0062] The coding gene sequence of the tyrosine phenol lyase is specifically shown in sequence 2 in the seque...

Embodiment 2

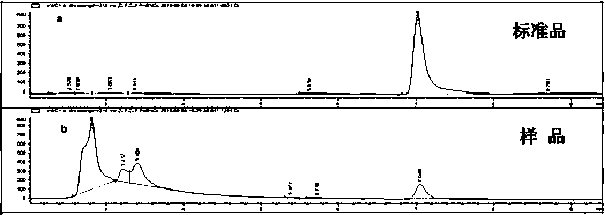

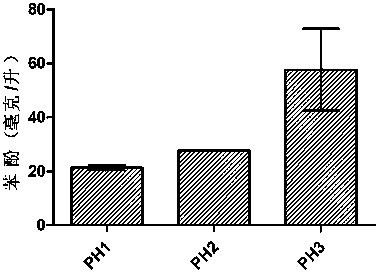

[0115] Example 2: Fermentation to produce phenol with glycerol as substrate

[0116] 1. The fermentation process of using glycerol to produce phenol

[0117] The E. coli engineered strain is preferably:

[0118] PH1: ATCC31884-pTrc99a-tpl-p4m;

[0119] PH2: ATCC31884-pTrc99a-tpl-p4m-trcglpX-tktA;

[0120] PH3: ATCC31884-pTrc99a-tpl-trcp4m-trcglpX-tktA;

[0121] The culture medium involved in the fermentation and production of phenol is preferably:

[0122] Solid plate medium (g / L): peptone 10, sodium chloride 10, yeast powder 5, agar 15, pH 7.0, add Amp 100μg / mL to the medium if necessary;

[0123] Fermentation seed medium (g / L): peptone 10, sodium chloride 10, yeast powder 5, pH 7.0, filling volume 10mL / 20mL, add Amp 100μg / mL to the medium if necessary;

[0124] Fermentation medium (g / L): glycerol 10, Na 2 HPO 4 ·12H 2 017.11, KH 2 PO 4 3. NaCl 0.5, NH 4 Cl 1, MgSO 4 ·7H 2 O0.492, CaCl 2 ·6H 2 O 0.022, filling volume 10mL / 20mL, add Amp 100μg / mL to the medium if necessary;

[0125] (1) Seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com