Preparation method of fluorine-doped lamellar black titanium dioxide nano material

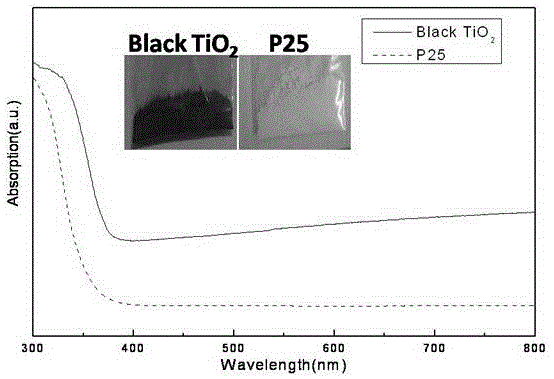

A technology of black titanium dioxide and nanomaterials, applied in the field of nanomaterials, can solve the problems of visible light absorption and the influence of carrier transport and separation ability, and achieve the effect of improving photocatalytic performance, enhancing performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

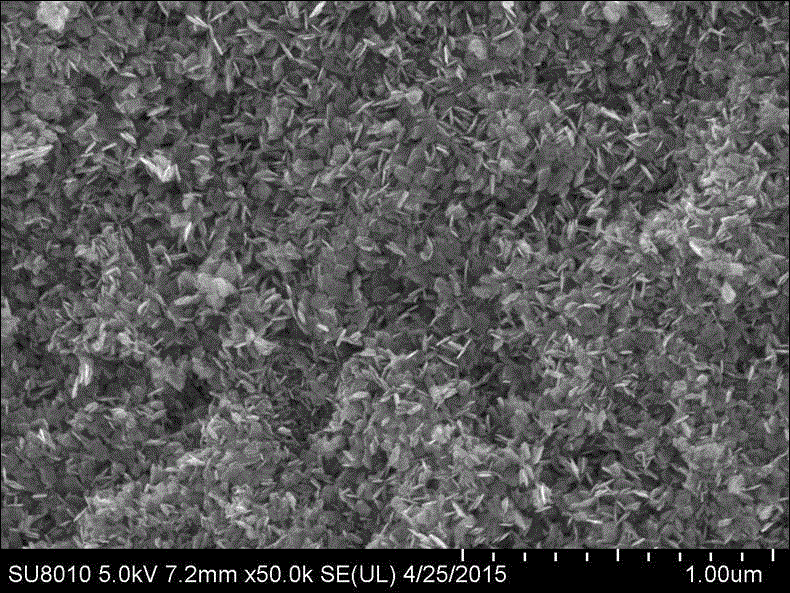

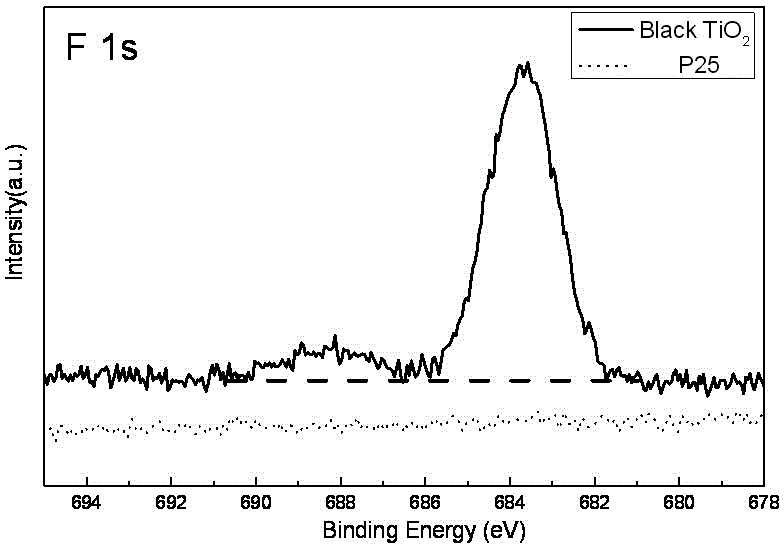

Embodiment 1

[0020] (1) Add 25mL of n-propanol into the beaker, then add 2mL of tetra-n-butyl titanate, and stir well;

[0021] (2) Add 0.4mL of hydrofluoric acid to the solution, then stir for 2 hours;

[0022] (3) Transfer the obtained solution to a high-pressure reactor, and conduct a hydrothermal reaction at 180°C for 18 hours;

[0023] (4) Wash the precipitate obtained after the reaction with deionized water and absolute ethanol until the filtrate is neutral, and then dry it;

[0024] (5) The obtained sample was calcined at 430°C under an atmosphere of argon and hydrogen to obtain fluorine-doped lamellar black titanium dioxide nanomaterials.

Embodiment 2

[0026] (1) Add 20mL of n-propanol into the beaker, then add 1mL of tetra-n-butyl titanate, and stir well;

[0027] (2) Add 0.15mL of hydrofluoric acid to the solution, then stir for 1 hour;

[0028] (3) Transfer the obtained solution to a high-pressure reactor, and conduct a hydrothermal reaction at 180°C for 15 hours;

[0029] (4) Wash the precipitate obtained after the reaction with deionized water and absolute ethanol until the filtrate is neutral, and then dry it;

[0030] (5) Calcining the obtained sample at 450°C under an atmosphere of argon and hydrogen to obtain fluorine-doped black sheet-like titanium dioxide nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com