Honeycomb graded-structure nanometer manganese dioxide and preparation method thereof

A technology of nano-manganese dioxide and hierarchical structure, which is applied in the field of materials science, can solve problems such as complex preparation methods, cumbersome operation steps, and single structure of manganese dioxide, and achieve good electrochemical performance and improved specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

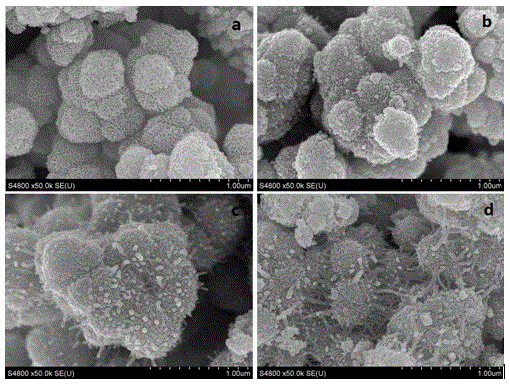

Image

Examples

Embodiment 1

[0025] (1) Solution preparation: Mix potassium permanganate and urea at a ratio of 1:1, the amount of each substance is 6mmol and add 48mL deionized water to prepare a concentration of 0.125mol / L. Magnetic stirring for 1h;

[0026] (2) Hydrothermal synthesis: transfer the solution in (1) into a 60mL pressure-resistant reactor, heat at 120°C for 12 hours to obtain a brown-black suspension, and filter the brown-black suspension to obtain a filter residue. Alternately wash 3 times with deionized water and ethanol, and then dry the product at 80°C for 3h;

[0027] (3) Roasting: Put the dried sample in (2) into a muffle furnace and bake at 320°C for 5 hours, and obtain the final solid manganese dioxide powder after cooling.

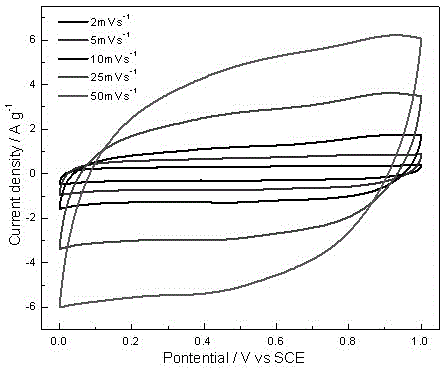

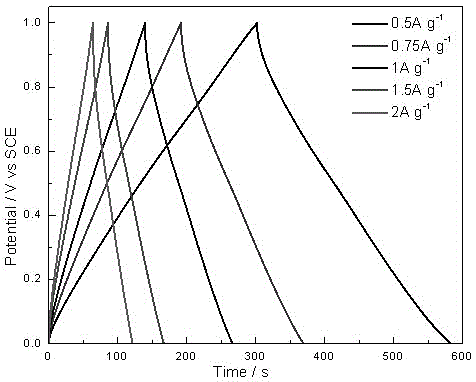

[0028] According to the mass ratio of active material manganese dioxide: acetylene black: PTFE = 80:15:5, it is coated on foamed nickel as a working electrode, and its specific capacitance can be tested on Chenhua CHI-660E electrochemical workstation. Reache...

Embodiment 2

[0030] (1) Solution preparation: Mix potassium permanganate and urea at a ratio of 1:1, the amount of each substance is 8mmol and add 48mL deionized water to prepare a concentration of 0.167mol / L. Magnetic stirring for 1h;

[0031] (2) Hydrothermal synthesis: transfer the solution in (1) into a 60mL pressure-resistant reactor, heat at 140°C for 11 hours to obtain a brown-black suspension, and filter the brown-black suspension to obtain a filter residue. Alternately wash 3 times with deionized water and ethanol, and then dry the product at 80°C for 3h;

[0032] (3) Roasting: Put the dried sample in (2) into a muffle furnace and bake at 350°C for 5 hours, and obtain the final solid manganese dioxide powder after cooling.

[0033] The finally obtained manganese dioxide powder is used as the supercapacitor electrode material, mixed according to the ratio of active material: acetylene black: PTFE = 80: 15: 5, and coated on the nickel foam as the working electrode. The electrochem...

Embodiment 3

[0035] (1) Solution preparation: Mix potassium permanganate and urea at a ratio of 1:1, the amount of each substance is 10mmol, and add 48mL deionized water to prepare a concentration of 0.208mol / L. Magnetic stirring for 1h;

[0036] (2) Hydrothermal synthesis: transfer the solution in (1) into a 60mL pressure-resistant reactor, heat at 120°C for 12 hours to obtain a brown-black suspension, and filter the brown-black suspension to obtain a filter residue. Alternately wash 3 times with deionized water and ethanol, and then dry the product at 80°C for 3h;

[0037] (3) Roasting: Put the dried sample in (2) into a muffle furnace and bake at 400°C for 2 hours, and obtain the final solid manganese dioxide powder after cooling.

[0038] The finally obtained manganese dioxide powder is used as the supercapacitor electrode material, mixed according to the ratio of active material: acetylene black: PTFE = 80: 15: 5, and coated on the nickel foam as the working electrode. The electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com