Method of determining content of arsenic element in coal-containing sample

A method for measuring arsenic, which is applied in the field of coal chemical industry, can solve the problems of poor accuracy and precision of measurement results, and achieve the effects of low detection limit, improved accuracy and precision, and fast test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

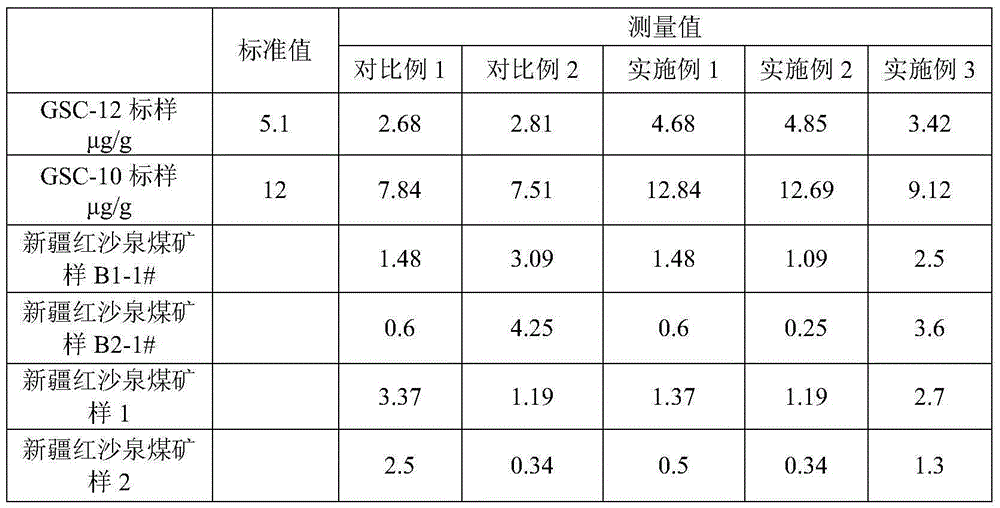

Examples

Embodiment 1 to 3

[0054] Use instrument and device among the embodiment 1 to 3:

[0055] XGY-1011A model atomic fluorescence spectrometer, arsenic single-element high-intensity hollow cathode lamp, argon gas (purity ≥ 99.99%), and the parameters of the atomic fluorescence spectrometer are shown in Table 1.

[0056] Table 1

[0057] the element

Embodiment 1

[0073] Weigh 2.00 g of the first Aldrin reagent in the crucible, and mix the above-mentioned first Erdrin reagent with 1.00 ± 0.0001 g of a coal-containing sample with a particle size of less than 0.2 mm to obtain a mixture, and then use 1.00 g of the second Aldrin Spread over the above mixture.

[0074] Put the crucible into the muffle furnace, heat it from room temperature to (800±10)°C within 2 hours, and keep it at this temperature for 2-3 hours, take out the crucible, cool it to room temperature, and get the burnt product.

[0075] Transfer the burning material to a 50mL polytetrafluoroethylene beaker, rinse the crucible with 18.3% hydrochloric acid solution for 2 to 3 times, carefully transfer the washing liquid in the crucible to the polytetrafluoroethylene beaker, and then add 15mL mass fraction The hydrochloric acid solution with a fraction of 18.3% is heated and dissolved on a low-temperature electric hot plate, then removed and cooled, and water is added to the abov...

Embodiment 2

[0080] In a 25mL polyethylene test tube, mix 0.4500g of the coal-containing sample with 10mL (1+1) aqua regia, place the above polyethylene test tube in a boiling water bath for 1 hour, shake it once during the period, take it out and cool it to obtain a digestion solution . To the above digestion solution, add 1mL10g / LKMnO 4 solution, shake it up and place it for 30 minutes to obtain the first system to be reacted;

[0081] Then add 14mL of 10g / L oxalic acid solution to the first system to be reacted to make the volume of the first system to be reacted is 25mL, shake well, and place to obtain a clear solution.

[0082] Mix 5.0mL of clear solution, 2.5mL of 1g / L ferric chloride solution and 1mL of 5%wt thiourea-5%wt ascorbic acid solution to obtain the solution to be tested, shake well, and stand for 30min.

[0083] In a hydride generator, reduce 2.0mL of the above-mentioned solution to be tested with 20.00mL of 7g / L potassium borohydride to obtain arsine; according to the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com