Efficient pesticide and insect-killing method thereof

An insecticide and high-efficiency technology, applied in the field of pesticides, can solve the problems of destroying the nutrient structure of the soil, difficult to use, low treatment efficiency, etc., and achieve the effects of low dosage, convenient operation and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

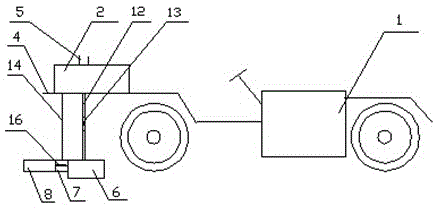

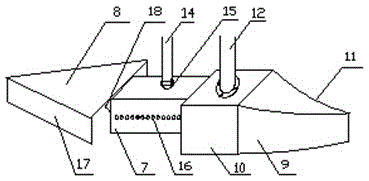

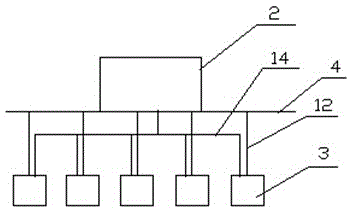

Method used

Image

Examples

Embodiment 1

[0032] A high-efficiency insecticide described in this embodiment is made of the following raw materials in parts by weight: 6 parts of ginkgo testa, 13 parts of Leiwan, 8 parts of Zanthoxylum bungeanum, 5 parts of Tiankuizi, 7 parts of Fructus Cnidii, 9 parts of rattan, 9 parts of Kochia scoparia, 8 parts of windproof, 100 parts of xylene, 5 parts of ethylene oxide propylene oxide copolymer, 0.6 parts of lignosulfonate, 4 parts of urea, 2 parts of organosilane defoamer , 40 parts of rice washing water.

[0033] The preparation method of described high-efficiency insecticide comprises the following steps:

[0034] (1) Extract 13 parts of Leiwan, 8 parts of Zanthoxylum bungeanum, 5 parts of Geranium, 7 parts of Cnidium, 9 parts of Tripterygium wilfordii, 9 parts of Kochia scoparia, and 8 parts of Fangfeng with super-zero carbon dioxide to obtain a concentration of 2g / ml of extract solution, the extraction temperature is 50°C, and the pressure is 29MPa;

[0035] (2) Smash 6 p...

Embodiment 2

[0053] A high-efficiency insecticide described in this embodiment is made of the following raw materials in parts by weight: 5 parts of Ginkgo exocarp, 15 parts of Leiwan, 6 parts of Zanthoxylum bungeanum, 8 parts of Tiankuizi, 5 parts of Fructus Cnidii, 12 parts of rattan, 6 parts of Kochia scoparia, 10 parts of windproof, 80 parts of solvent oil, 8 parts of alkylphenol polyoxyethylene ether formaldehyde condensate, 0.5 parts of naphthalenesulfonate, 5 parts of urea, 1 part of silicone defoamer , 50 parts of rice washing water.

[0054] The preparation method of described high-efficiency insecticide comprises the following steps:

[0055] (1) Extract 15 parts of Leiwan, 6 parts of Zanthoxylum bungeanum, 8 parts of Tiankuizi, 5 parts of Cnidium, 12 parts of Tripterygium wilfordii, 6 parts of Kochia scoparia, and 10 parts of Fangfeng with super-zero carbon dioxide to obtain a concentration of 1g / ml of extract solution, the extraction temperature is 53°C, and the pressure is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com