Preparation method of magnetic biomimetic carbon-based solid acid catalyst

A solid acid catalyst, an enzyme-like carbon-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as poor stability and catalytic activity , to achieve the effect of low production cost, enhanced hydrolysis capacity, and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

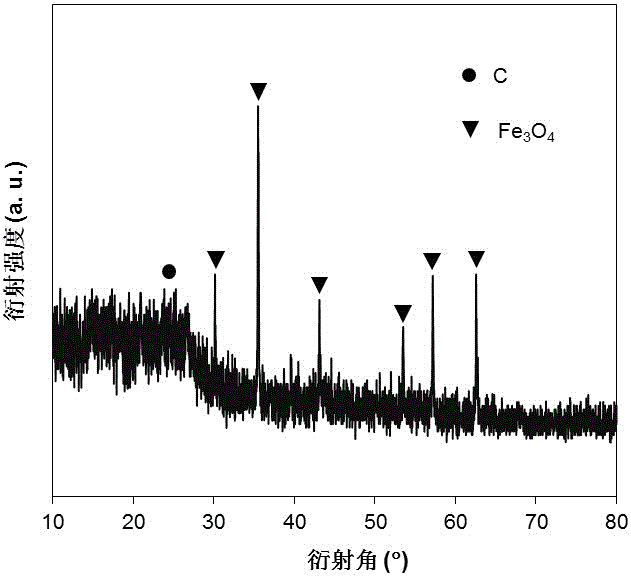

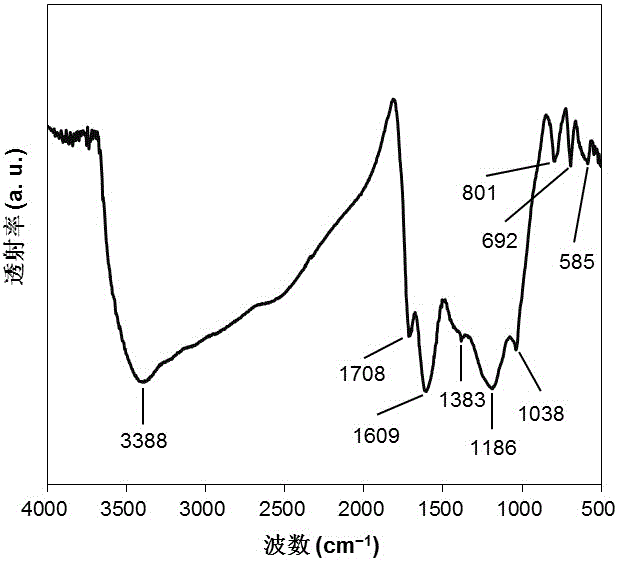

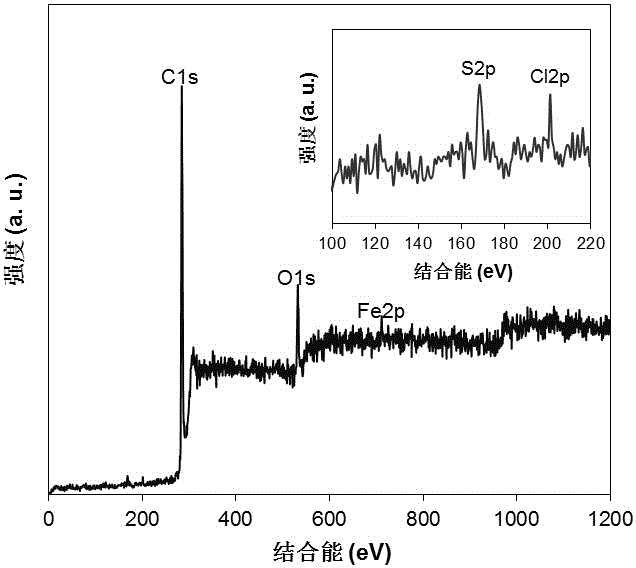

[0024] Example 1: Weigh 20 g of enzymatic hydrolysis residue lignin from corncobs, wash them with deionized water and absolute ethanol for 10 times, and vacuum-dry at 80°C for 12 hours; grind the enzymatic hydrolysis residue lignin after washing and drying to 120 mesh size, And it was added to the ferric chloride solution with a concentration of 20mmol / L at a mass volume ratio of 1:50 and stirred for 5h, then heated to evaporate excess water in the solution, and the remaining solid mixture was vacuum-dried at 80°C for 12h; The enzymolysis residue lignin after ferric chloride impregnation and drying was mixed with chloromethyl polystyrene resin at a mass ratio of 5:2, and then carbonized at 500°C for 1 hour under a nitrogen atmosphere to obtain a magnetic enzyme-like carbon carrier; after carbonization, The magnetic enzyme-mimetic carbon carrier was added to concentrated sulfuric acid at a mass volume ratio of 1:10 for sulfonation, stirred and heated at 150°C for 10h under a nit...

Embodiment 2

[0026] Example 2: Weigh 20 g of enzymatic hydrolysis residue lignin from corn stalks, wash with deionized water and absolute ethanol 10 times respectively, and vacuum-dry at 80°C for 12 hours; grind the enzymatic hydrolysis residue lignin after washing and drying to 120 mesh size, And it was added to the ferric chloride solution with a concentration of 10mmol / L at a mass volume ratio of 1:100 and stirred for 10h, then heated to evaporate excess water in the solution, and the remaining solid mixture was vacuum-dried at 80°C for 12h; The enzymolysis residue lignin impregnated with ferric iron and dried was mixed with sucralose at a mass ratio of 10:1, and then carbonized at 500°C for 1 hour under a nitrogen atmosphere to obtain a magnetic enzymatic carbon carrier; the carbonized magnetic enzymatic carbon The carrier was added to concentrated sulfuric acid at a mass volume ratio of 1:30 for sulfonation, stirred and heated at 80°C for 24 hours under a nitrogen atmosphere; the sulfo...

Embodiment 3

[0028] Example 3: Weigh 20g of bagasse enzymolysis residue lignin, wash with deionized water and absolute ethanol 10 times respectively, and vacuum-dry at 80°C for 12 hours; grind the enzymolysis residue lignin after washing and drying to 120 mesh size, And it was added to the ferric chloride solution with a concentration of 25mmol / L at a mass volume ratio of 1:75 and stirred for 7h, then heated to evaporate excess water in the solution, and the remaining solid mixture was vacuum-dried at 80°C for 12h; Ferric chloride impregnated and dried enzymolysis residue lignin was mixed with polyvinyl chloride at a mass ratio of 5:1, and then carbonized at 500°C for 1 h under nitrogen atmosphere to obtain a magnetic imitation enzyme carbon carrier; the carbonized magnetic imitation enzyme The carbon carrier was added to concentrated sulfuric acid at a mass volume ratio of 1:20 for sulfonation, and stirred and heated at 200°C for 5 hours under a nitrogen atmosphere; the sulfonated magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com