Method for preparing polyimide film from reactive end-capped polyamic acid resin

A technology of polyimide film and end-capped polyamic acid, applied in the field of polyimide film, can solve the problems of low molecular weight of polyamic acid resin, affecting product performance, and decreasing the strength and toughness of polyimide film. , to achieve the effects of high strength, high toughness, heat resistance stability, simplified production process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

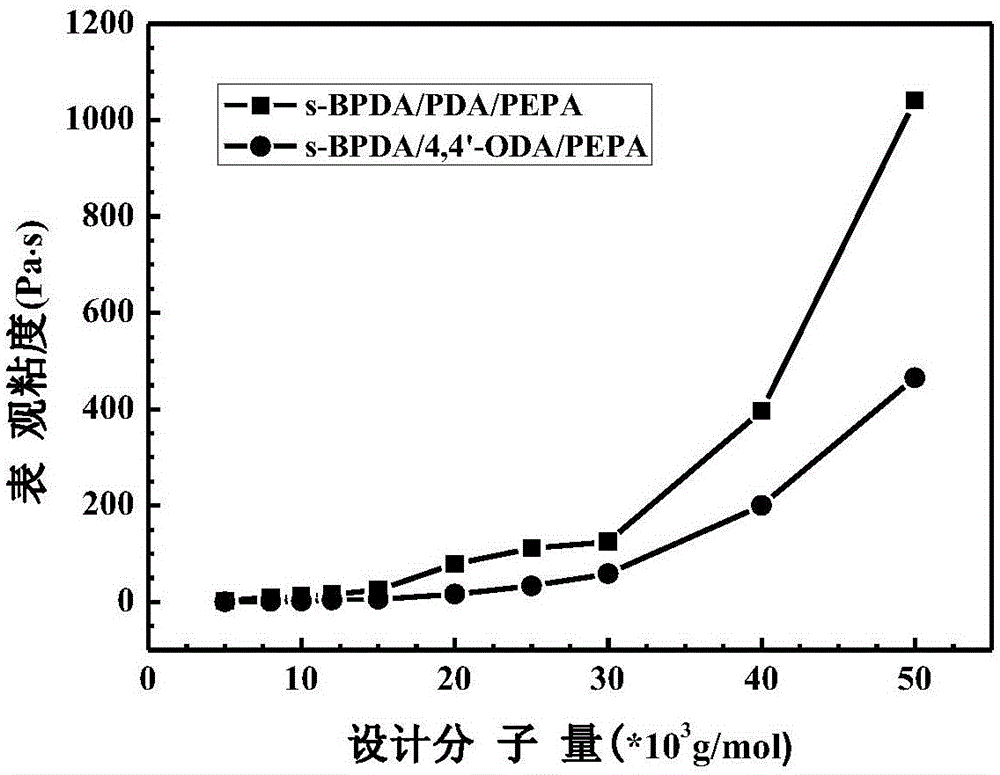

[0043] (1) Add 18.6720g (0.1727mol) of PDA and 150g of DMAc into a 500ml three-neck flask equipped with a mechanical stirrer and a spherical reflux condenser, stir mechanically at 50°C until they are completely dissolved, and then rapidly lower the ambient temperature to 25°C, Simultaneously increase the stirring rate, slowly add the mixture of dried 49.8607g (0.1695mol) s-BPDA and 1.5862g (0.0064mol) 4-PEPA while stirring, supplement 130.48gDMAc to rinse the bottle wall and the residue on the stirring paddle monomer, until the solid content of the solution is 20wt.%, continue stirring for 24h until the solution is clear, and the design molecular weight is 2×10 4 g / mol reddish-brown 4-PEPA-terminated polyamic acid resin solution, wherein the designed mole fraction of anhydride end groups in 4-PEPA accounts for 1.85% of the total anhydride groups, and its apparent viscosity at 25°C is 109000cP (109Pa· s), the intrinsic viscosity is 0.72dl / g; the obtained polyamic acid solution ...

Embodiment 2

[0049] (1) adopting the method identical with embodiment 2 steps (1) to prepare design molecular weight is 2.5 * 10 4 g / mol polyamic acid resin, wherein the design mole fraction of anhydride end groups in 4-PEPA accounts for 1.48% of the total anhydride groups, the difference is the amount of monomer added: PDA plus 18.6744g (0.1727mol), s- BPDA plus 50.0566g (0.1701mol), 4-PEPA plus 1.2665g (0.0051mol), supplemented DMAc plus 129.99g. The apparent viscosity of the obtained 4-PEPA-terminated polyamic acid resin solution at 25° C. was 111,000 cP (111 Pa·s), and the intrinsic viscosity was 0.76 dl / g.

[0050] (2) The 4-PEPA-terminated polyamic acid film was prepared by the same method as in step (2) of Example 1, except that the standard gap of the coating rod was 450 μm.

[0051] (3) The polyimide film was prepared by the same method as in step (3) of Example 1, and the main properties of the obtained film are shown in Table 2.

[0052] The main properties of table 2 polyimid...

Embodiment 3

[0055] (1) adopting the method identical with embodiment 1 step (1) to prepare design molecular weight is 3.0 * 10 4 g / mol polyamic acid resin, wherein the design mole fraction of anhydride end groups in 4-PEPA accounts for 1.23% of the total anhydride groups, the difference is the amount of monomer added: PDA plus 18.7157g (0.1731mol), s- BPDA plus 50.2935g (0.1709mol), 4-PEPA plus 1.0563g (0.0043mol), supplemented DMAc plus 130.26g. The apparent viscosity of the obtained polyamic acid resin solution at 25°C was 125000cP (125Pa·s), and the intrinsic viscosity was 0.80dl / g.

[0056] (2) The 4-PEPA-terminated polyamic acid film was prepared by the same method as in step (2) of Example 1, except that the standard gap of the coating rod was 400 μm.

[0057] (3) The polyimide film was prepared by the same method as in step (3) of Example 1, and the main properties of the obtained film are shown in Table 3.

[0058] Table 3 Main properties of polyimide film

[0059] mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com