A kind of preparation method of nano-boehmite composite graphene oxide anti-wear lubricant

A nano-boehmite and anti-wear lubricant technology, which is used in the preparation of polymer composite materials, can solve the problems of long reaction time and poor dispersion of graphene oxide, and achieve low cost, low friction coefficient, and reduced wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of nano-boehmite composite graphene oxide anti-wear lubricant, comprising the following steps:

[0021] (1) Preparation of graphene oxide (GO): Take 0.8g of graphite and add it to a 500mL flask, then add 24mL of 95% concentrated sulfuric acid to the beaker, put the flask in ice water and stir for 30min at a stirring speed of 600r / min, then add 1g NaNO 3 Stir, stirring speed is 600r / min, add 5g KMnO again after 30min 4 , stirred at 600r / min for 2h, then moved to an oil bath at 39°C, stirred for another 2.5h at a stirring speed of 600r / min, then slowly added 41mL of deionized water dropwise with a constant pressure dropper, and raised the bath temperature to 95°C and then 800r / min stirred for 1.5h, and finally added dropwise 120mL 10% H with a constant pressure dropper 2 o 2 , Stir at 1000r / min until the color of the reaction system turns from golden yellow to black, immediately add 100mL of HCl with a concentration of 0.5mol / L, stir at 1000r / min ...

experiment example 1

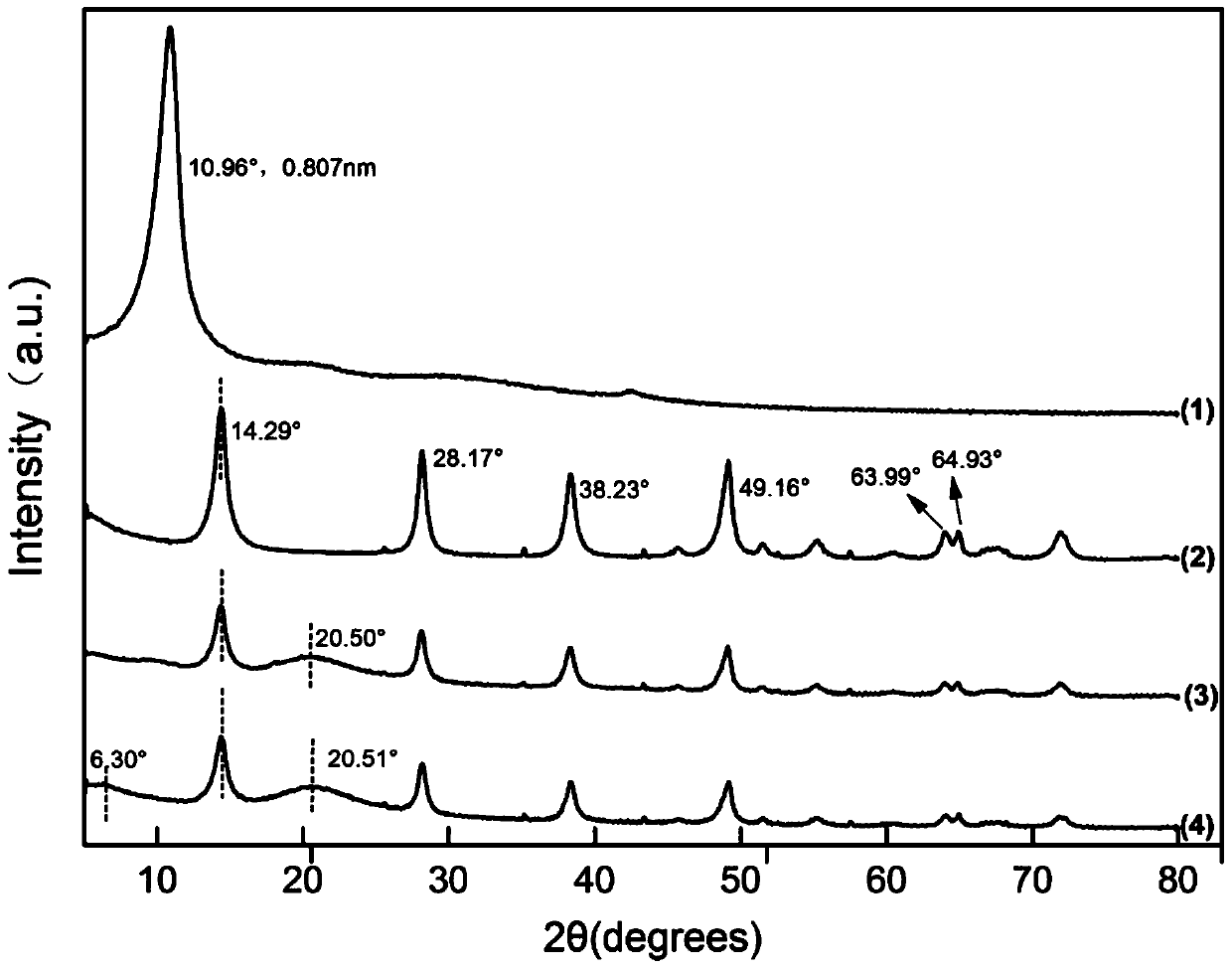

[0024] Experimental example 1 is to the XRD pattern analysis of sample of the present invention

[0025] Depend on figure 1 It can be seen that the graphene oxide (GO) sample only has a very strong diffraction peak at 2θ=10.96°, and the interplanar spacing d≈0.81nm can be calculated by the Bragg formula, indicating that the degree of graphite oxidation is relatively high, and the prepared GO has a high purity. very high. Nano-boehmite (AlOOH) belongs to orthorhombic crystal structure, and the obtained hybrid boehmite (A-K) has a broad peak near 2θ=20.50°, which is due to the existence of silane coupling agent (KH560 ) independent amorphous phase structure. In the diffraction spectrum of nano-boehmite composite graphene oxide (A-K-G), the characteristic peak of GO disappeared, and a broad and weak peak appeared at 2θ=6.30° (interlayer spacing d≈1.4nm), indicating that the graphene oxide sheets The stacking method of the structure has changed to a great extent, with larger la...

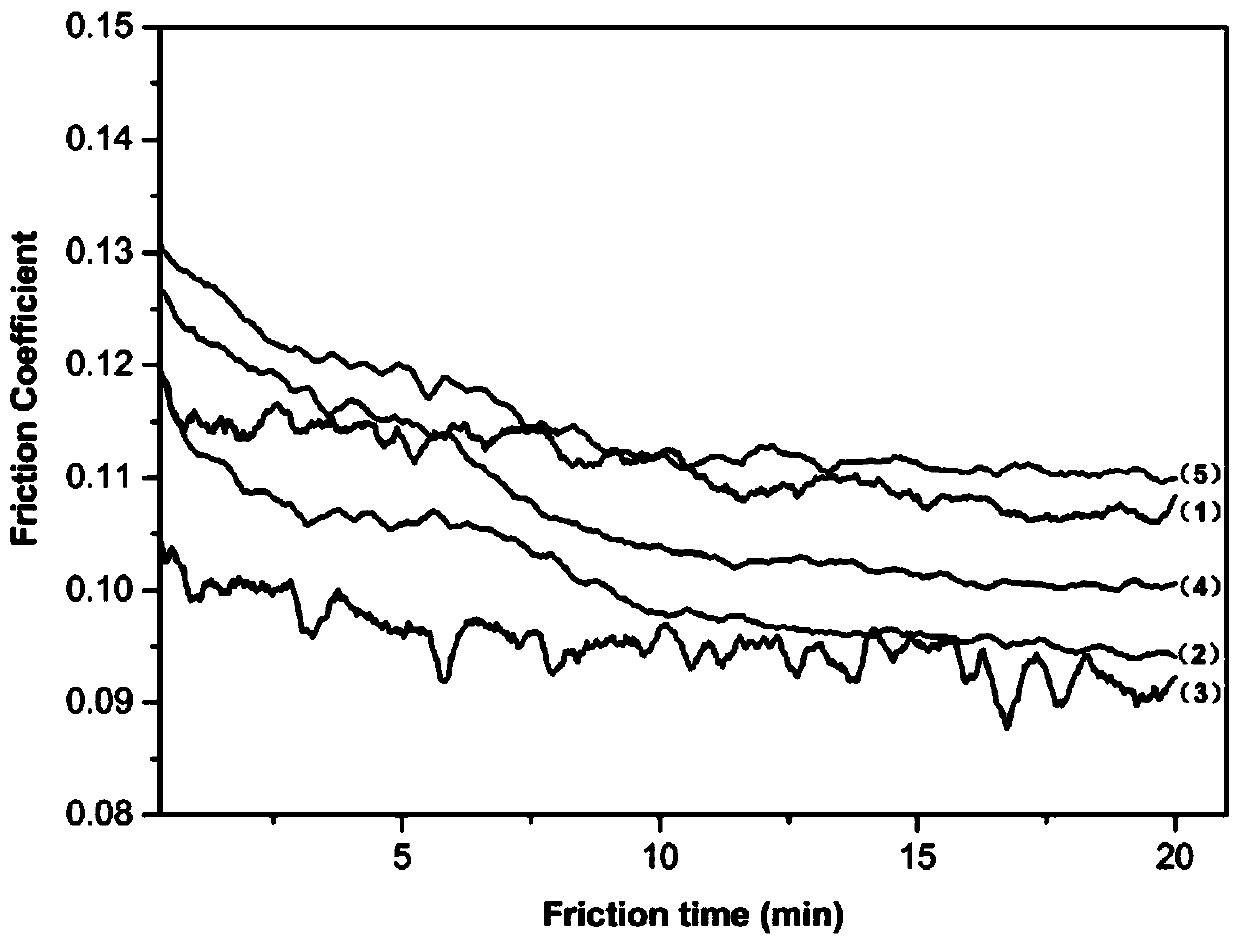

experiment example 2

[0026] Experimental Example 2 Preparation of nanocomposite lubricating oil with different concentrations by using A-K-G and lubricating base oil VHVI8

[0027] (1) Preparation of a nanocomposite lubricating oil with a concentration of 0.015mg / g

[0028] Accurately weigh 1.5mg of A-K-G, add 100g of lubricating oil base oil VHVI8, ultrasonically disperse in a water bath at 60°C for 2 hours, and let it stand for 24 hours to prepare a nanocomposite lubricating oil with a concentration of 0.015mg / g.

[0029] (2) preparation concentration is the nanocomposite lubricating oil of 0.030mg / g

[0030]Accurately weigh 3.0mg of A-K-G, add 100g of lubricating base oil VHVI8, ultrasonically disperse in a water bath at 60°C for 2 hours, and let it stand for 24 hours to prepare a nanocomposite lubricating oil with a concentration of 0.030mg / g.

[0031] (3) preparation concentration is the nanocomposite lubricating oil of 0.045mg / g

[0032] Accurately weigh 4.5mg of A-K-G, add 100g of lubrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com