Tin and copper carbon nanotube composite coating of automobile terminal, electroplating liquid and electroplating method for tin and copper carbon nanotube composite coating of automobile terminal

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of preparation of tin-copper carbon nanotube composite coating for automobile terminals, can solve the problems of increased insertion and extraction force, assembly difficulty, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

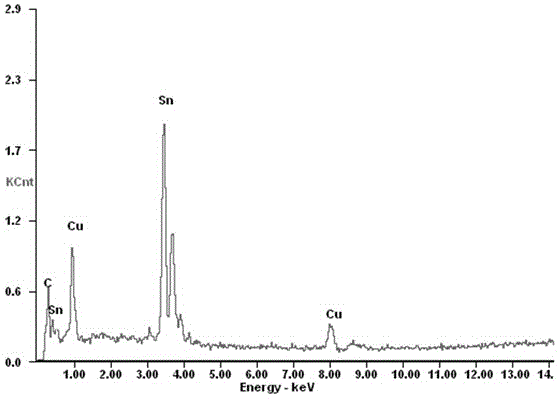

Image

Examples

Embodiment 1

[0019] A kind of electroplating solution that the tin-copper carbon nanotube composite coating of automobile terminal adopts, formula is as follows: stannous sulfate 25g / L, copper sulfate 5g / L, citric acid 45g / L, tartaric acid 40g / L, 98% sulfuric acid 95mL / L, 2-mercaptobenzimidazole 0.6mg / L, sodium dodecylsulfonate 0.05g / L, carbon nanotube 1.5g / L.

[0020] A kind of electroplating method of tin-copper carbon nanotube composite coating of automobile terminal, the steps are as follows:

[0021] (1) Add deionized water to the cleaned plating tank, slowly add 98% sulfuric acid, add stannous sulfate, copper sulfate, citric acid, tartaric acid and 2-mercaptobenzimidazole after the solution is cooled to 25°C, and Stir continuously to dissolve and form solution A;

[0022] (2) Add sodium lauryl sulfate and carbon nanotubes into deionized water, and disperse them by ultrasonic waves for 8 minutes to form solution B;

[0023] (3) Add solution B to solution A, hang the tin anode and th...

Embodiment 2

[0026] A kind of electroplating solution that tin-copper carbon nanotube composite coating of automobile terminal adopts, formula is as follows: tin protosulfate 35g / L, copper sulfate 1g / L, citric acid 55g / L, tartaric acid 30g / L, 98% sulfuric acid 105mL / L, 2-mercaptobenzimidazole 0.1mg / L, sodium dodecylsulfonate 0.2g / L, carbon nanotube 0.5g / L.

[0027] A kind of electroplating method of tin-copper carbon nanotube composite coating of automobile terminal, the steps are as follows:

[0028] (1) Add deionized water to the cleaned plating tank, slowly add 98% sulfuric acid, add stannous sulfate, copper sulfate, citric acid, tartaric acid and 2-mercaptobenzimidazole after the solution is cooled to 35°C, and Stir continuously to dissolve and form solution A;

[0029] (2) Add sodium lauryl sulfate and carbon nanotubes into deionized water, and disperse them by ultrasonic waves for 15 minutes to form solution B;

[0030] (3) Add solution B to solution A. At this time, if the total a...

Embodiment 3

[0033] A kind of electroplating solution that the tin-copper carbon nanotube composite coating of automobile terminal adopts, formula is as follows: tin protosulfate 30g / L, copper sulfate 3g / L, citric acid 50g / L, tartaric acid 35g / L, 98% sulfuric acid 100mL / L, 2-mercaptobenzimidazole 0.4mg / L, sodium dodecylsulfonate 0.1g / L, carbon nanotube 1g / L.

[0034] A kind of electroplating method of tin-copper carbon nanotube composite coating of automobile terminal, the steps are as follows:

[0035] (1) Add 60L of deionized water to the cleaned plating tank, slowly add 98% sulfuric acid, add 30g stannous sulfate, 3g / copper sulfate, 50g citric acid, 35g tartaric acid and 0.4mg2 -Mercaptobenzimidazole, and constantly stirring makes the dissolution be made into solution A;

[0036] (2) Add 0.1g of sodium lauryl sulfate and 1g of carbon nanotubes into 5L of deionized water, and disperse them by ultrasonic waves for 10 minutes to form solution B;

[0037] (3) Add solution B to solution A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com