Processing method of pearl liquid, pearl ginseng liquid and pearl powder easily absorbed by human body

A processing method and technology of pearl powder, which can be used in pharmaceutical formulations, medical raw materials derived from molluscs, plant raw materials, etc., can solve the problems of expensive, polluting the environment, and reducing the hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0178] Using a 5000mL conical flask, use citric acid to reflux and hydrolyze the keratin of 2000g of Martens pearl layer powder to produce "Martens pearl liquid, Martens pearl ginseng liquid and Martens pearl powder easily absorbed by the human body". Martens nacre powder contains 3.74% keratin.

[0179] Add 200g of Marshmallow pearl layer powder to hydrochloric acid such as [A] Formula (I): V 盐酸31% = M 马氏珍珠层粉 × 2.0605 = 200 × 2.0605 = 412.10mL, dissolve it until the pH is 6.4-6.6. Dilute to 3000mL, filter through filter paper, and discard the liquid. Then use filtered water to thoroughly wash the pearl keratin on the filter paper. Merge 10 parts of keratin of total 2000g Marshmallow's nacre powder.

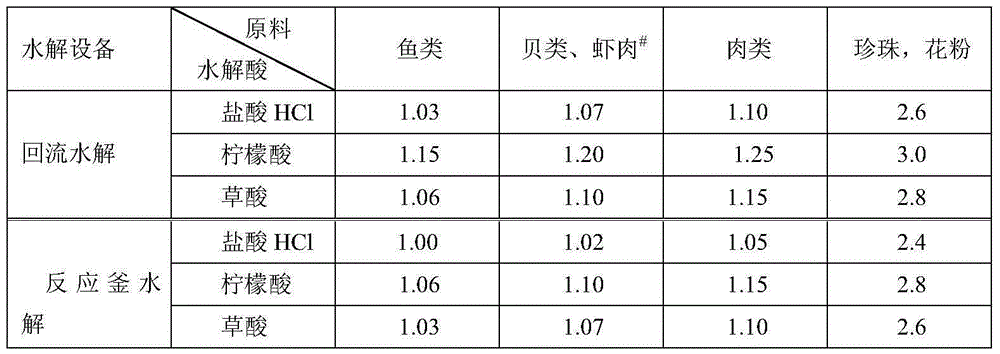

[0180] Calculate the citric acid used for hydrolysis. from [B] In formula (Ⅱ-1), choose CC=3.0:

[0181] m 柠檬酸 = Raw material protein amount×3.0×2.1947=Raw protein amount×6.5841.

[0182] Martens nacre powder contains keratin 3.74%, M 壳蛋白 = M 马氏珍珠层 x 3.74% = 2000 x 3....

Embodiment 2

[0192] Using a 10L stainless steel reaction kettle, citric acid is used to hydrolyze 5000g of the horn shell protein of the spinosa pearl powder to produce "the spinosa pearl liquid, the spinosa pearl ginseng liquid and the human body can easily absorb the spinosa pearl powder". Triangle clam pearls contain 3.2% keratin.

[0193] Add 200g of spinosa clam pearl powder to hydrochloric acid such as [A] Formula (I): V 盐酸31% = M 冠蚌珍珠粉 × 2.0605 = 200 × 2.0605 = 412.10mL, dissolve it until the pH is 6.4-6.6. Dilute to 3000mL, filter through filter paper, and discard the solution. Then use filtered water to thoroughly wash the pearl keratin on the filter paper. Merge 25 parts of keratin shell proteins of 5000g Hypophylla mussel pearl powder in total.

[0194] Calculate the citric acid used for hydrolysis. from [B] In formula (Ⅱ-1), choose CC=2.8:

[0195] m 柠檬酸 = Raw protein amount×2.8×2.1947=Raw protein amount×6.1452.

[0196] Triangle clam pearls contain keratin 3.2%, M 壳...

Embodiment 3

[0207] Using a 10L stainless steel reactor, citric acid is used to hydrolyze 5000g of pleat clam pearl powder's keratin shell protein to produce "pleat clam pearl liquid, pleat clam pearl ginseng liquid and pleat clam pearl powder that can be easily absorbed by the human body". The pleated crown clam pearl contains 3.4% keratin.

[0208] Add 200g of pleated crown clam pearl powder to hydrochloric acid such as [A] Formula (I): V 盐酸31% = M 冠蚌珍珠粉 × 2.0605 = 200 × 2.0605 = 412.10mL, dissolve it until the pH is 6.4-6.6. Dilute to 3000mL, filter through filter paper, and discard the solution. Then use filtered water to thoroughly wash the pearl keratin on the filter paper. Merge 25 parts of keratin of total 5000g pleated crown clam pearl powder.

[0209] Calculate the citric acid used for hydrolysis. from [B] In formula (Ⅱ-1), choose CC=2.8:

[0210] m 柠檬酸 = Raw protein amount×2.8×2.1947=Raw protein amount×6.1452.

[0211] Pleated Crown Mussel Pearl Contains 3.4% Keratin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com