Method of preventing and controlling chromium pollution in dark green glass production and used chelate fiber

A chelating fiber, dark green technology, applied in water pollutants, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem of reducing the reuse efficiency of chelating resins, cumbersome multi-stage extraction process, and expensive extraction agents to achieve excellent regeneration performance, high adsorption selectivity, and short adsorption equilibrium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

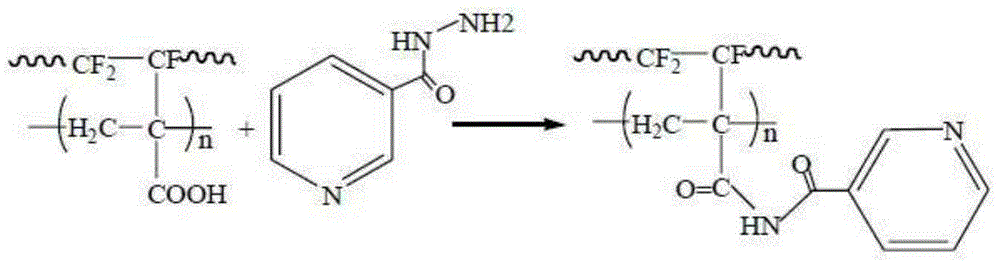

[0043] Embodiment 1, a kind of method of synthetic chelating fiber NTHF, carry out following steps successively:

[0044] 1) Put about 20.0mg of the matrix---grafted acrylic polytetrafluoroethylene fiber (PTFE-g-AA) into a 100mL three-necked bottle, add 50mL of N,N-dimethylformamide and soak for 12 hours;

[0045] Remarks: The content of PTFE-g-AA functional group (ie -COOH) in grafted acrylic polytetrafluoroethylene fiber (PTFE-g-AA) is 3.07mmol / g.

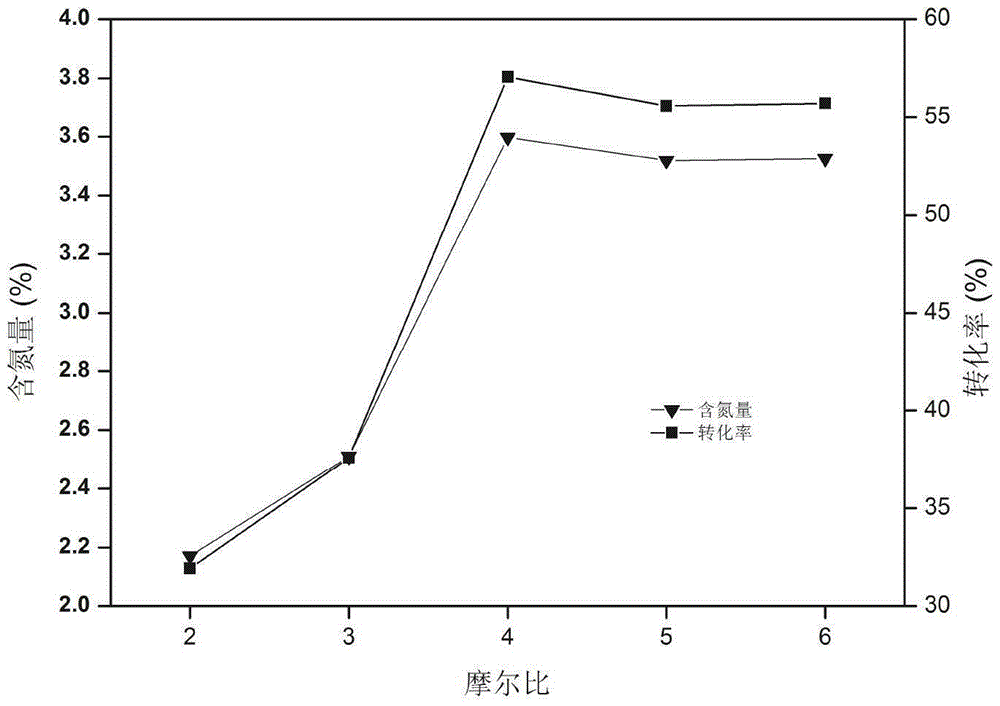

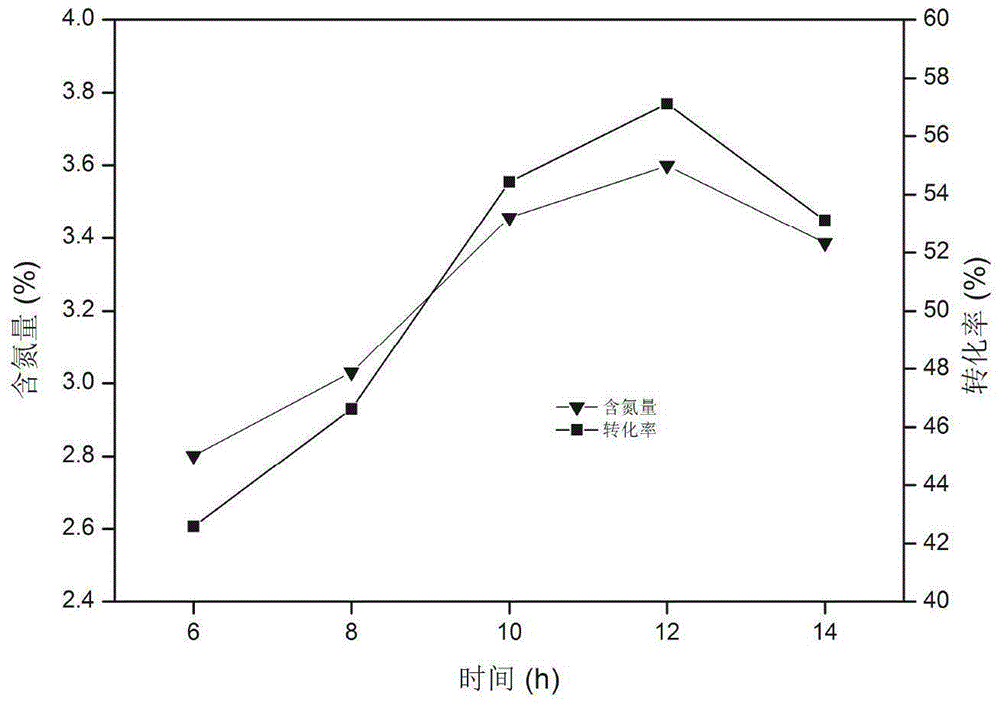

[0046] 2), then add 0.246mmol of ligand——nicotinic acid hydrazide (that is, the reaction molar ratio of PTFE-g-AA and ligand is 1:4) to the three-necked flask, stir and react at 35°C for 12 hours, stir The speed of the machine is 300rpm / min.

[0047] 3), filter the product obtained in step 2), and wash the obtained filter cake with N,N-dimethylformamide, ether, ethanol, and deionized water three times in sequence, each time: N,N-dimethyl The amount of formamide, ether, ethanol, and deionized water is 100ml;

[0048] Put the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com