Spinel type composite ultrafine blue ceramic pigment and preparation method thereof

A spinel-type, ceramic pigment technology, applied in the field of ceramic pigments, can solve the problems of unfavorable industrial production, complicated operation steps, difficulty in quality assurance, etc., and achieve the effects of bright color, simple and controllable process, and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 3

[0032] First, 22.509g of glycine was dissolved in 120mL of distilled water, and then 14.552g of Co(NO 3 ) 2 ·6H 2 O and 37.513g of Al(NO 3 ) 3 ·6H 2 O, put it on a magnetic stirrer with a set temperature of 60°C to dissolve and stir until the solution is completely dissolved to obtain a clear liquid (about 20 minutes). Then heated to 110 ° C for 100 minutes, during which the liquid viscous expansion, followed by release of gas, rapid self-propagating combustion reaction, forming a loose powder. The obtained powder was calcined at 900°C for 4 hours to obtain the blue nano-pigment CoAl 2 o 4 .

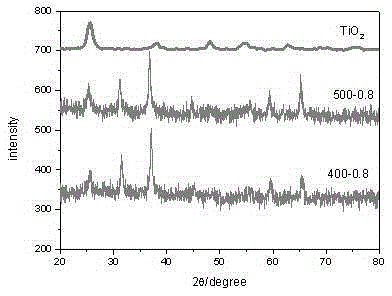

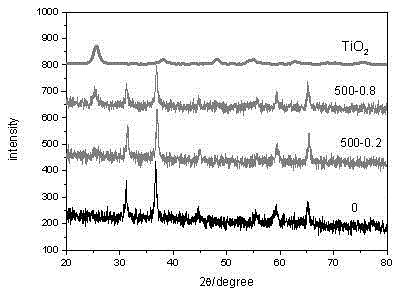

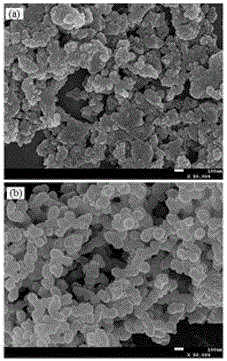

Embodiment 1

[0034] A kind of preparation method of spinel type composite ultrafine blue ceramic pigment, it comprises the steps:

[0035] 1) 2gCoAl 2 o 4 Add it into 100mL water, stir evenly to get solution A;

[0036] 2) Mix 0.852g butyl titanate (0.2g titanium dioxide after conversion) with 2 volume times absolute ethanol to obtain solution B;

[0037] 3) Add solution B dropwise to solution A under stirring conditions, stir at room temperature for 5 hours at a speed of 90 rpm, and then leave to age for 24 hours to obtain an opaque gel;

[0038] 4) The opaque gel obtained in step 3) was first dried at 80°C for 4 hours, then dried at 90°C for 2 hours, then ground to obtain a loose precursor powder, and finally transferred to a muffle furnace for calcination at 400°C for 5 hours to obtain spinel type compound (CoAl 2 o 4 / TiO 2 ) Ultrafine blue ceramic pigment.

Embodiment 2

[0040] A kind of preparation method of spinel type composite ultrafine blue ceramic pigment, it comprises the steps:

[0041] 1) 2gCoAl 2 o 4 Add it into 100mL water, stir evenly to get solution A;

[0042] 2) Mix 3.409g butyl titanate (0.8g titanium dioxide after conversion) with 3 volume times absolute ethanol to obtain solution B;

[0043] 3) Add solution B dropwise to solution A under stirring conditions, stir at room temperature at a speed of 90 rpm for 6 hours, and then stand and age for 48 hours to obtain an opaque gel;

[0044] 4) The opaque gel obtained in step 3) was first dried at 80°C for 4 hours, then dried at 90°C for 2 hours, then ground to obtain a loose precursor powder, and finally transferred to a muffle furnace for calcination at 400°C for 5 hours to obtain spinel type compound (CoAl 2 o 4 / TiO 2 ) Ultrafine blue ceramic pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com