Flame-retardant anti-corrosion coating for electrical equipment

A kind of electric equipment and anti-corrosion technology, applied in the direction of anti-corrosion coating, fire-proof coating, polyester coating, etc., can solve the problems that the equipment status cannot be analyzed and judged in real time, and the conditions for condition-based maintenance are not available, so as to reduce the aging phenomenon of asphalt , easy processing and use, and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

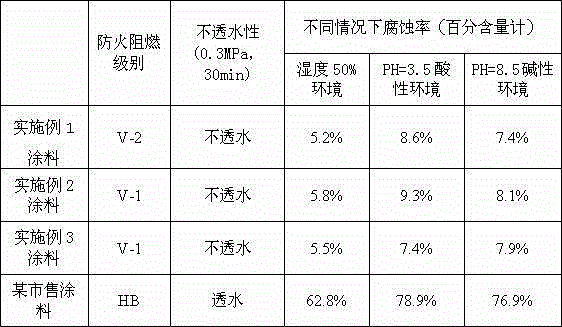

Examples

Embodiment 1

[0040] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment consists of the following components in parts by mass: 40 parts of ammonium parahydrogen phosphate, 42 parts of high-gloss barium, 38 parts of montmorillonite powder, 42 parts of barite powder, 38 parts of imide, 42 parts of triazine resin, 38 parts of butyl tin mercaptide, 44 parts of dibutyl maleate, 38 parts of benzoyl peroxide, 42 parts of acrylate copolymer suspension, SBS modification 38 parts of asphalt, 42 parts of polydimethylsiloxane, 38 parts of trimethylolpropane, 42 parts of triacrylate, 38 parts of cobalt naphthenate, 42 parts of vinyl silicone resin, 38 parts of aluminum hydroxide, mineral wool 42 parts of fiber, 38 parts of vinyl benzene, 42 parts of ethylene bis stearamide, 38 parts of modified ricinoleic acid polyester, 42 parts of polyol aluminum dihydrogen phosphate, 1000 parts of water.

[0041] The steps of the method for preparing the above-mentioned flam...

Embodiment 2

[0046] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment is composed of the following components in parts by mass: 42 parts of ammonium parahydrogen phosphate, 44 parts of high-gloss barium, 40 parts of montmorillonite powder, 44 parts of barite powder, 40 parts of imide, 44 parts of triazine resin, 40 parts of butyl tin mercaptide, 46 parts of dibutyl maleate, 40 parts of benzoyl peroxide, 44 parts of acrylate copolymer suspension, SBS modification 40 parts of asphalt, 44 parts of polydimethylsiloxane, 40 parts of trimethylolpropane, 44 parts of triacrylate, 40 parts of cobalt naphthenate, 44 parts of vinyl silicone resin, 40 parts of aluminum hydroxide, mineral wool 44 parts of fiber, 40 parts of vinylbenzene, 44 parts of ethylene bis stearamide, 40 parts of modified ricinoleic acid polyester, 44 parts of polyol aluminum dihydrogen phosphate, 1500 parts of water.

[0047] The steps of the method for preparing the above-mentioned fl...

Embodiment 3

[0052] The flame-retardant and corrosion-resistant coating for electric equipment in this embodiment is composed of the following components in parts by mass: 44 parts of ammonium parahydrogen phosphate, 46 parts of high-gloss barium, 42 parts of montmorillonite powder, 46 parts of barite powder, 42 parts of imide, 46 parts of triazine resin, 42 parts of butyl tin mercaptide, 48 parts of dibutyl maleate, 42 parts of benzoyl peroxide, 46 parts of acrylate copolymer suspension, SBS modification 42 parts of asphalt, 46 parts of polydimethylsiloxane, 42 parts of trimethylolpropane, 46 parts of triacrylate, 42 parts of cobalt naphthenate, 46 parts of vinyl silicone resin, 42 parts of aluminum hydroxide, mineral wool 46 parts of fiber, 42 parts of vinylbenzene, 46 parts of ethylene bis stearamide, 42 parts of modified ricinoleic acid polyester, 46 parts of polyol aluminum dihydrogen phosphate, 2000 parts of water.

[0053] The steps of the method for preparing the above-mentioned fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com