Photocatalyst antibacterial silent composite floor and process for manufacturing same

A photocatalyst antibacterial and composite floor technology, applied in the direction of building, floor, building structure, etc., can solve the problem of floor structure and its performance to be improved, and achieve the effect of solving insect and ant erosion, prolonging storage period, and lasting insect control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

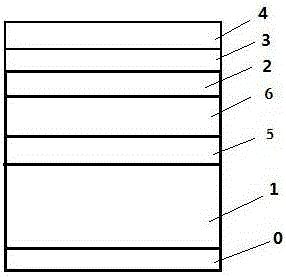

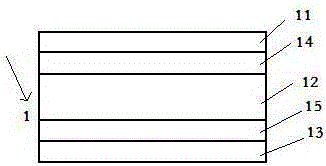

Image

Examples

Embodiment 1

[0074] Biomass soybean gum preparation: add 3g of alkali and 100g of water in a three-neck round bottom flask, the alkali is sodium hydroxide, stir for 3 minutes to dissolve the sodium hydroxide, then add 0.5g of silicate, 0.5 g sulfite and 0.2g modifier, the silicate is sodium silicate, the modifier is urea, the sulfite is sodium sulfite, and stirred for 3 minutes, the temperature is 80-96 °C to obtain a preliminary mixed solution; then add 15 g of soybean derivatives to the preliminary mixed solution, the soybean derivatives are soybean protein isolate, stir for 10 minutes, and the temperature is 80 °C, so that the soybean protein isolate is fully dispersed in the solution, Obtain a mixed solution; then add 0.3 g of an aqueous solution of curing agent polyamide polyamine-epichlorohydrin (PAE) with a mass concentration of 12.5%, and stir for 10 minutes to obtain a solidified mixed solution; then add an acid, the acid being 0.1 The mass concentration of phosphoric acid was 35%...

Embodiment 2

[0103] Preparation of biomass soybean gum: Add 8g of alkali and 100g of water into a three-neck round bottom flask, the alkali is sodium hydroxide, stir for 10 minutes to dissolve the sodium hydroxide, then add 3g of silicate and 3g of sulfite to the alkali solution And 5g modifier, silicate is sodium silicate, modifier is urea, sulfite is sodium sulfite, and stirs 10 minutes, and temperature is 96 ℃, obtains preliminary mixed solution; Then in the preliminary mixed solution Add 40g of soybean derivatives, the soybean derivatives are soybean protein isolate, stir for 60 minutes at a temperature of 96°C, so that the soybean protein isolate is fully dispersed in the solution to obtain a mixed solution; then add 2.5g of curing agent with a mass concentration of 12.5% The aqueous solution of polyamide polyamine-epichlorohydrin (PAE) was stirred for 60 minutes to obtain a solidified mixed solution; then an acid was added, and the acid was 4 g of phosphoric acid with a mass concentra...

Embodiment 3

[0132] Preparation of biomass soybean gum: Add 5g of alkali and 100g of water into a three-neck round bottom flask, the alkali is sodium hydroxide, stir for 6 minutes to dissolve the sodium hydroxide, then add 2g of silicate and 2g of sulfite to the alkali solution and 2g modifier, the silicate is sodium silicate, the modifier is urea, the sulfite is sodium sulfite, and stirred for 6 minutes, the temperature is 90 ° C, to obtain a preliminary mixed solution; then to the preliminary mixed solution Add 25g of soybean derivatives, the soybean derivatives are soybean protein isolate, stir for 30 minutes, and the temperature is 90°C, so that the soybean protein isolate is fully dispersed in the solution to obtain a mixed solution; then add 3g of curing agent polymer with a mass concentration of 12.5%. The aqueous solution of amidopolyamine-epichlorohydrin (PAE) was stirred for 30 minutes to obtain a solidified mixed solution; then an acid was added, and the acid was 2 g of phosphori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com