Field effect diode and manufacturing method therefor

A technology of field effect diodes and manufacturing methods, applied in the direction of diodes, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of difficult control of the depth of trench etching, complicated manufacturing process, high turn-on voltage, etc., and achieve low reverse The effects of leakage current, simple manufacturing process, and low forward turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

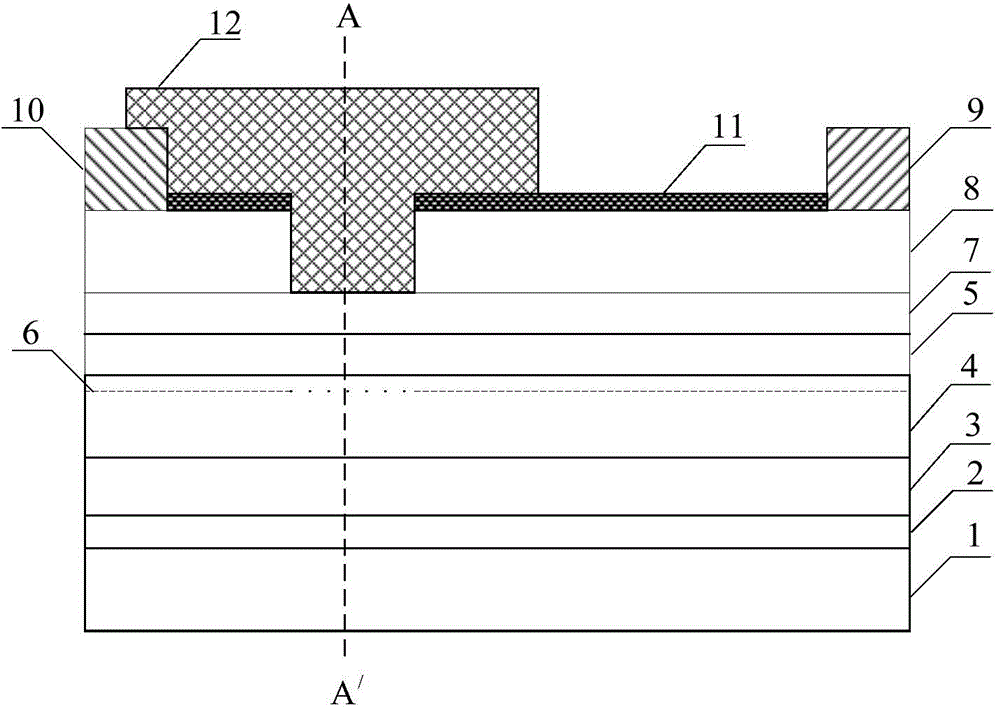

[0050] figure 1 It is a structural diagram of a field effect diode provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the field effect diode consists of:

[0051] Substrate 1.

[0052] In this embodiment, the substrate material may be gallium nitride, silicon, sapphire or silicon carbide.

[0053] The nucleation layer 2 is located on the substrate 1 .

[0054] In this embodiment, the nucleation layer material may be aluminum nitride, gallium nitride or aluminum gallium nitride,

[0055] The buffer layer 3 is located on the nucleation layer 2 .

[0056] In this embodiment, the material of the buffer layer may be AlGaN or other III-V group compounds, and the thickness may be 1-3.5 microns.

[0057] The channel layer 4 is located on the buffer layer 3 .

[0058] In this embodiment, the material of the channel layer may be gallium nitride, and the thickness may be 15-35 nanometers.

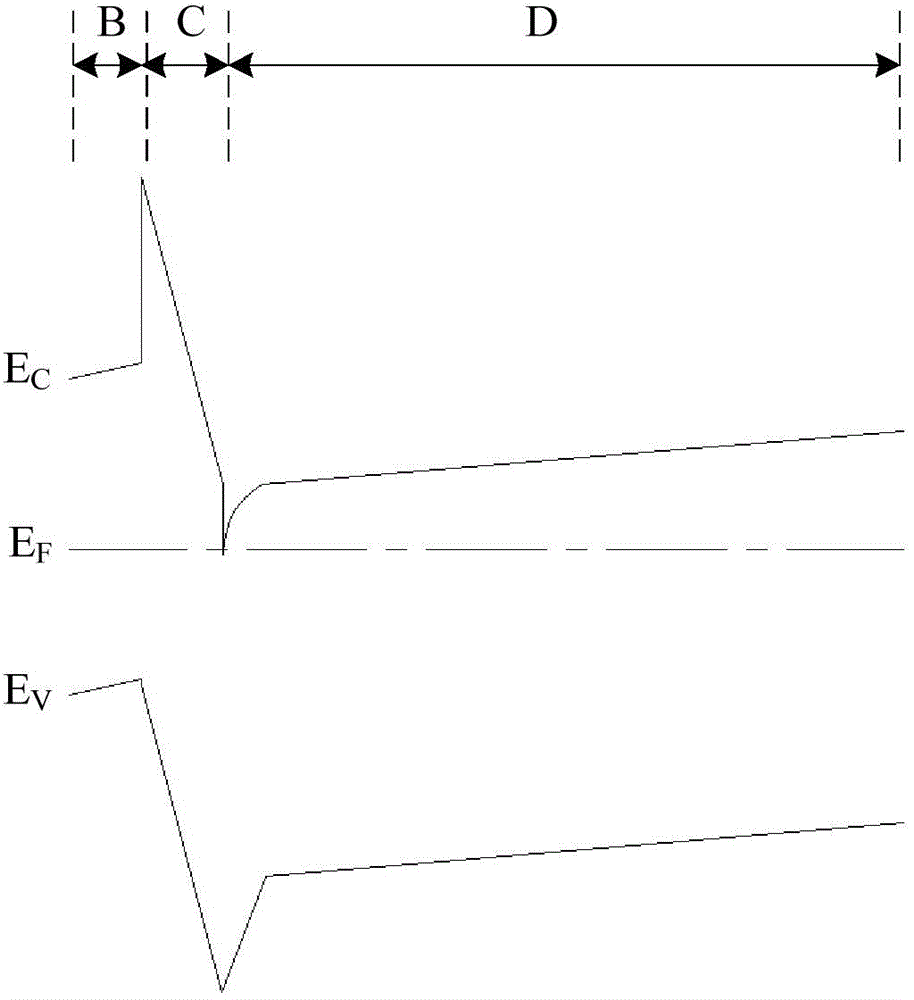

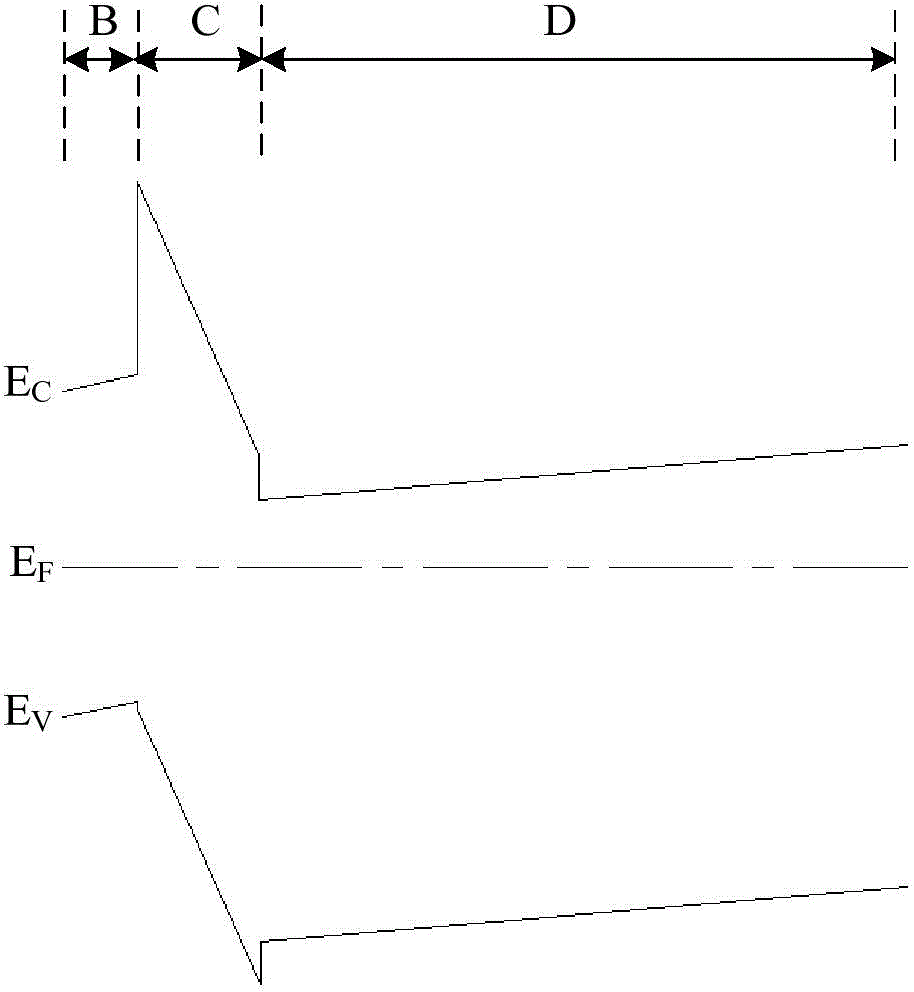

[0059] The first barrier layer 5 is located on the channel layer ...

Embodiment 2

[0108] Figure 6 It is the structure diagram of the field effect diode provided by the second embodiment of the present invention. Such as Figure 6 As shown, different from the first embodiment of the present invention, the field effect diode provided by the second embodiment of the present invention further includes: a back barrier layer 13 located between the buffer layer 3 and the channel layer 4 .

[0109] In this embodiment, the material of the back barrier layer may be P-type GaN or P-type AlGaN. In this structure, the negative charge introduced by the P-type doping in the back barrier layer and the negative charge generated by the piezoelectric polarization further suppress the two-dimensional electron gas concentration in the channel layer, which can further regulate the turn-on voltage of the diode. , so as to obtain a turn-on voltage that is positive and close to 0V.

[0110] Figure 7 It is a flow chart of the manufacturing method of the field effect diode prov...

Embodiment 3

[0116] Figure 8 It is the structure diagram of the field effect diode provided by the third embodiment of the present invention. Such as Figure 8 As shown, different from the first embodiment of the present invention, the mass percentage of the aluminum component of the second barrier layer 8 of the field effect diode provided by the third embodiment of the present invention gradually decreases from top to bottom, and the shape of the trench is Inverted trapezoid.

[0117] In this embodiment, the mass percentage of the aluminum component of the second barrier layer gradually increases from bottom to top, showing a gradient change. During the thermal oxidation process of the second barrier layer, the degree of oxidation varies with the mass percentage of the aluminum component, and the higher the mass percentage of the aluminum component, the easier it is to be oxidized. Therefore, in the process of corroding and forming grooves, the part with a high mass percentage of alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com