Preparation method of hydroxyapatite-coated lithium titanate

A technology of hydroxyapatite and coating lithium titanate, applied in active material electrodes, electrical components, battery electrodes, etc., can solve the problem that the speed of energy release is not fast enough, the precipitation of lithium dendrites is a safety hazard, and the charging and discharging platform is low, etc. problem, to achieve excellent electrochemical performance, low price, and the effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

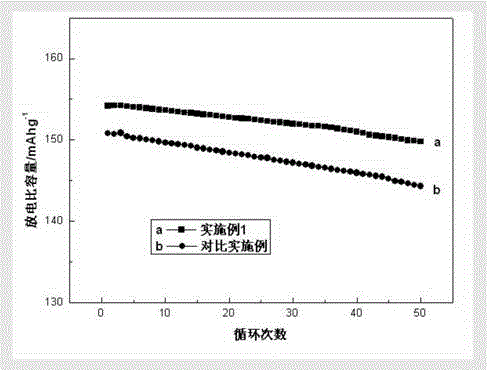

Embodiment 1

[0020] A preparation method for hydroxyapatite-coated lithium titanate, comprising the following steps:

[0021] (1) Using isopropanol as a solvent, prepare a concentration of 0.1mol / L lithium hydroxide solution and a concentration of 0.1mol / L tetrabutyl titanate solution respectively;

[0022] (2) Ultrasonic disperse 0.0735g of hydroxyapatite with a mass fraction of 1% in isopropanol, add 0.0735g of ethylenediaminetetraacetic acid with a mass fraction of 1%, and slowly add 40mL of the solution under constant magnetic stirring. 1mol / L lithium hydroxide solution, 50mL 0.1mol / L tetrabutyl titanate solution, in which the molar ratio of lithium ions to titanium ions is 4:5; stir in a water bath at 40°C for 1 hour to obtain a gel, and place the gel in Vacuum drying at 60°C, grinding and crushing to obtain the precursor;

[0023] (3) The precursor was placed in a muffle furnace, and calcined at 650° C. for 5 hours in an air atmosphere to obtain a hydroxyapatite-coated lithium titan...

Embodiment 2

[0026] A preparation method for hydroxyapatite-coated lithium titanate, comprising the following steps:

[0027] (1) Using absolute ethanol as a solvent, prepare a concentration of 0.5mol / L lithium acetate solution respectively, and a concentration of 0.6mol / L tetraethyl titanate;

[0028] (2) Ultrasonic disperse 1.1020 g of hydroxyapatite with a mass fraction of 3% in absolute ethanol, add 1.1020 g of oxalic acid with a mass fraction of 3%, and slowly add 60 mL of 0.5 mol / L lithium acetate under constant magnetic stirring Solution, 62.5mL0.6mol / L tetraethyl titanate, in which the molar ratio of lithium ions to titanium ions is 4:5; stir in a water bath at 50°C for 3h to obtain a gel, and dry the gel in vacuum at 70°C , grinding and pulverizing to obtain the precursor;

[0029] (3) The precursor was placed in a muffle furnace and calcined at 750° C. for 6 hours in an air atmosphere to obtain a lithium titanate negative electrode material coated with hydroxyapatite.

[0030] ...

Embodiment 3

[0032] A preparation method for hydroxyapatite-coated lithium titanate, comprising the following steps:

[0033] (1) taking diethanolamine as solvent, preparing concentration respectively is 1mol / L lithium nitrate solution, and concentration is 1.1mol / L tetraisopropyl titanate solution;

[0034] (2) Ultrasonic dispersion of 1.8366g of hydroxyapatite with a mass fraction of 5% in diethanolamine, adding 3.6732g of citric acid with a mass fraction of 10%, and slowly adding 40mL of 1mol / L lithium nitrate solution under constant magnetic stirring, 45.5 mL of 1.1 mol / L tetraisopropyl titanate solution, in which the molar ratio of lithium ions to titanium ions is 4:5; stir in a water bath at 60°C for 5 hours to obtain a gel, and vacuum-dry the gel at 70°C , grinding and pulverizing to obtain the precursor.

[0035] (3) The precursor was placed in a muffle furnace and calcined at 800° C. for 8 hours in an air atmosphere to obtain a hydroxyapatite-coated lithium titanate negative elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com