A method of electrical stimulation to promote the bioreductive decomposition of volatile chlorinated hydrocarbons

A technology of volatile and chlorinated hydrocarbons, applied in the direction of using microorganisms, etc., can solve the problems of slow degradation, incomplete decomposition, toxic and harmful intermediate products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

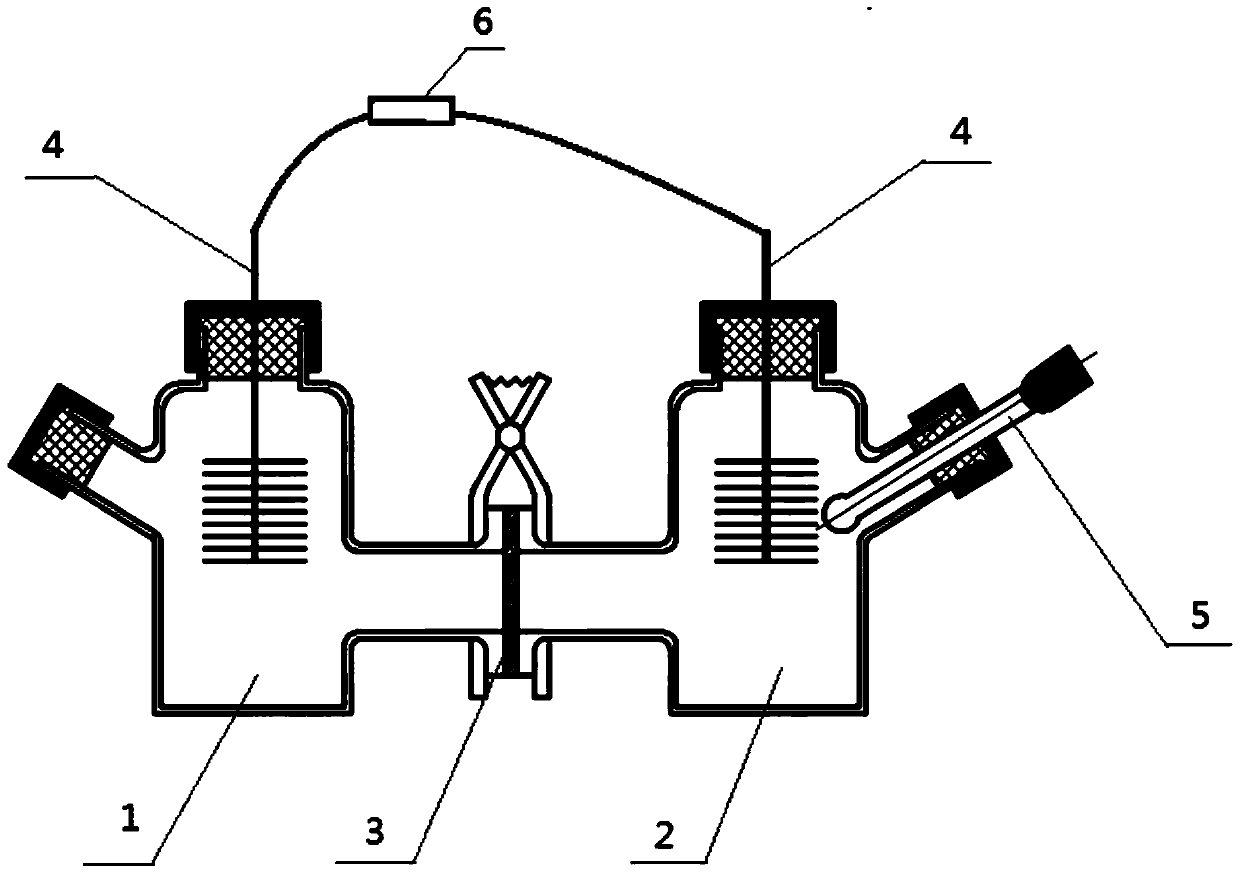

[0015] Specific implementation mode 1: The method for promoting the bioreductive decomposition of volatile chlorinated hydrocarbons by electrical stimulation according to this embodiment is carried out in the following steps:

[0016] 1. The preparation of the culture medium: add the distilled water and the activated sludge to the glass bottle at the ratio of 50mL of distilled water to 10-15mL of activated sludge. After blowing nitrogen for 15~20min, seal it to keep the bottle anaerobic and get the culture base;

[0017] 2. Enrichment and enhancement of functional flora: add sodium acetate solution and volatile chlorinated aliphatic hydrocarbons to the culture medium, place the culture medium in a constant temperature incubator at 30°C, and measure volatile chlorine every 3 to 5 days Degradation of substituted aliphatic hydrocarbons; when the content of volatile chlorinated aliphatic hydrocarbons drops below 50% of the initial concentration, add sodium acetate solution and volatile...

specific Embodiment approach 2

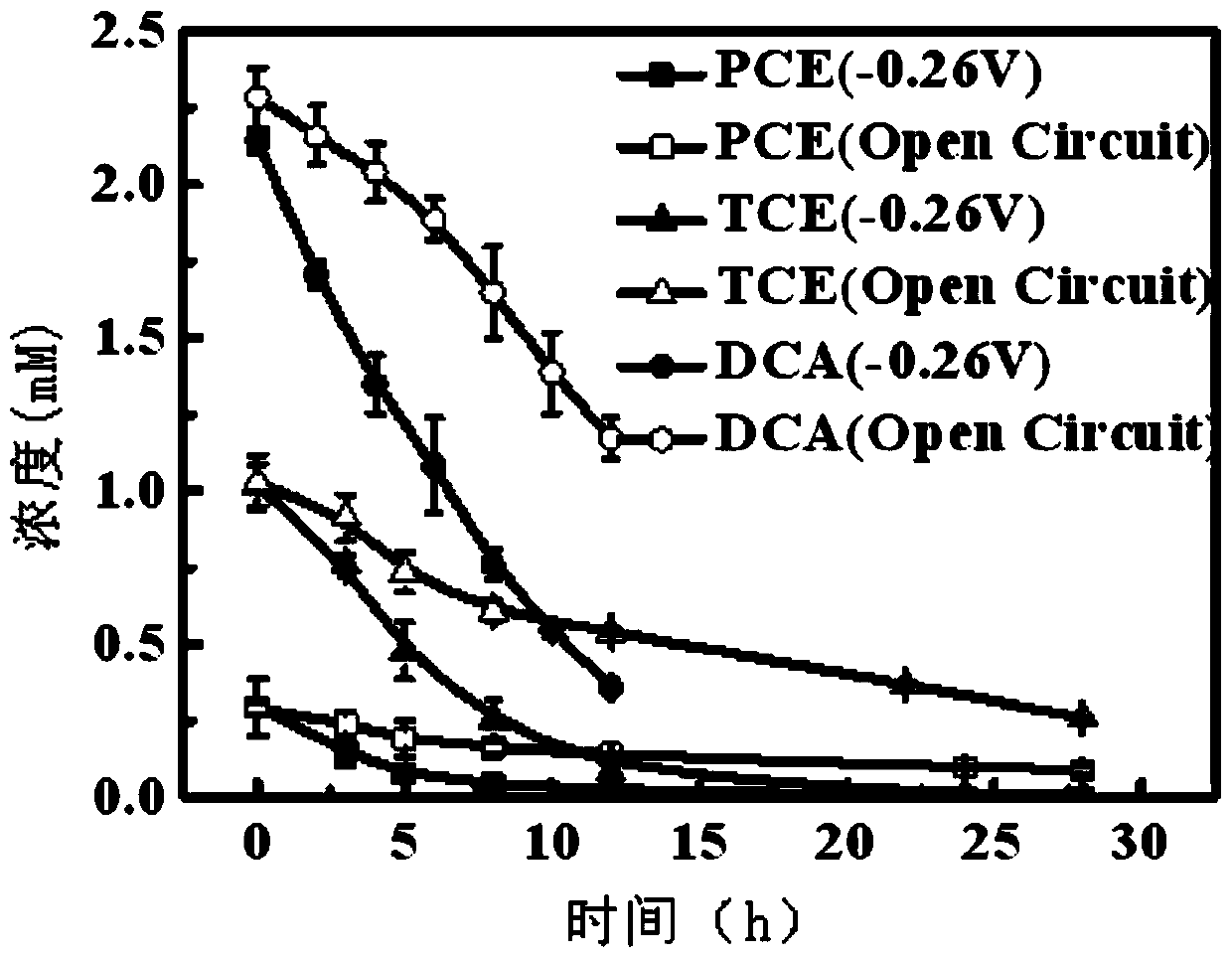

[0022] Specific embodiment two: this embodiment is different from specific embodiment one in that the volatile chlorinated aliphatic hydrocarbon in step two is trichloroethylene, tetrachloroethylene or 1,2-dichloroethane; the others are the same as specific embodiment one .

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment is different from specific embodiment one or two in that: the composition of the anaerobic culture solution described in step three is as follows: it is prepared at a ratio of the following components per 1000mL anaerobic culture solution: 11.55gNa 2 HPO 4 ·12H 2 O, 2.77g NaH 2 PO 4 ·2H 2 O, 0.31g NH 4 Cl, 0.13g KCl, 0.41g CH 3 COONa, 0.1mL vitamin solution, 0.1mL mineral element solution and the remainder of distilled water; wherein the vitamin solution contains 2.0mg vitamin H, 2.0mg folic acid, 10.0mg pyridoxine hydrochloride, 5.0mg thiamine per 1000mL vitamin solution Element, 5.0mg riboflavin, 5.0mg niacin, 5.0mg calcium D-pantothenate, 0.1mg vitamin B12, 5.0mg p-aminobenzoic acid, 5.0mg lipoic acid and the remainder of distilled water; the mineral element liquid is per 1000mL mineral element liquid contains 1.5g nitrilotriacetic acid, 3.0g MgSO 4 ·7H 2 O, 0.5gMnSO 4 ·H 2 O, 1.0g NaCl, 0.1g FeSO 4 ·7H 2 O, 0.1g CoCl 2 ·6H 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com