Metal ion imprinted amino functionalized mesoporous silicon adsorbent and preparation method thereof

A technology of metal ion imprinting and amine-based functions, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., and can solve the problem of weak anti-interference ability of coexisting ions, poor selective adsorption capacity, etc. problems, to achieve the effects of environmental protection, good regeneration performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

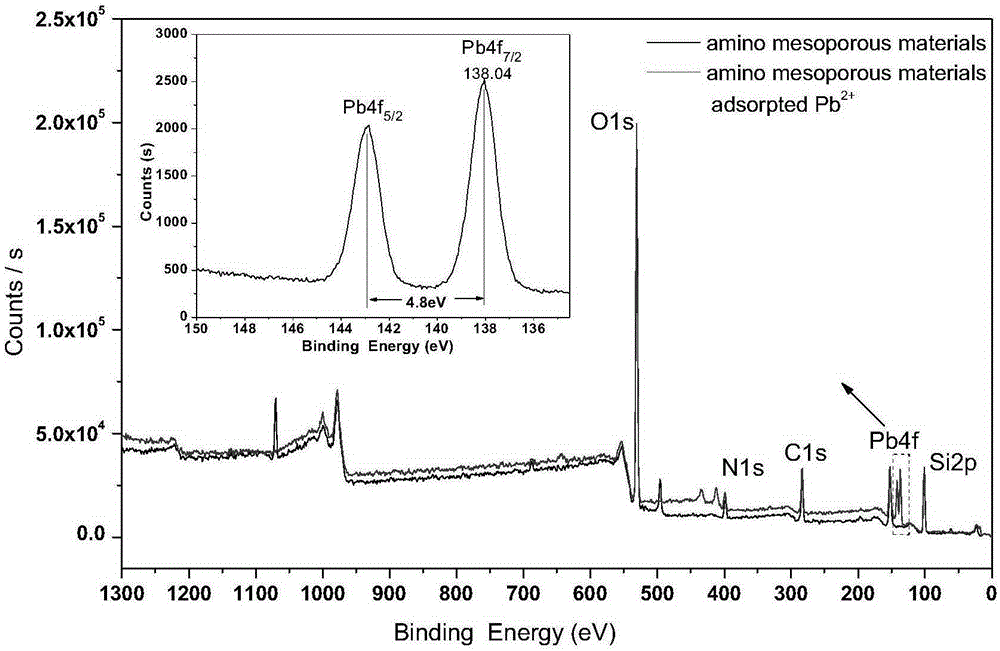

[0056] Example 1: The adsorbent uses the sol-gel method to synthesize a metal ion-imprinted amine functionalized mesoporous silica sol under alkaline conditions. During the volatilization of solvent ethanol, the sol gradually hydrolyzes and polycondenses to form a mesoscopic structure. After solvent volatilization, crystallization, template removal, filtration, washing, drying and other steps, the metal ion-imprinted amine functionalized mesoporous silicon adsorbent is finally obtained.

[0057] The described metal ion-imprinted amine functionalized mesoporous silica sol is a synthetic sol, and the material type and molar ratio of the synthetic sol are amino-containing silane coupling agent: orthosilicate: surfactant: HCl: quaternary ammonium base :H 2 O: ethanol: metal ion = (0.04-0.35): 1: (0.03-0.25): (0.01-0.10): (0.04-0.30): (4.55-10.50): (27-54): (0.01-0.35) ;

[0058] At 25°C, dissolve 2.32g of dihexadecyldimethylammonium bromide in 40g of ethanol and stir for 2 hours...

Embodiment 2

[0059] Example 2: At 40°C, 3.73g dodecylglucoside (mass concentration 50%) was dissolved in 20g ethanol, and ultrasonicated for 1.0 hour (ultrasonic power 300W); meanwhile, 1.37gN-β-aminoethyl- γ-Aminopropyltrimethoxysilane was dissolved in 30g of ethanol, under the condition of ultrasonic power of 500W, 0.86g of copper nitrate was added, and 3.14g of a mass concentration of 15% tetraethylammonium hydroxide aqueous solution was added dropwise, to A 10 mol / L hydrochloric acid solution adjusted the pH of the system to 12. After 1.0 hour, the above two solutions were mixed, and 4.34 g of methyl orthosilicate was added dropwise at a stirring speed of 300 rpm. After 1.5 hours, the prepared silica sol was placed in a constant temperature and humidity chamber until the solvent evaporated completely (humidity 30% RH, temperature 40° C.). The product was crystallized by microwave at 100°C for 2 hours (microwave power 300W), extracted at 80°C with a mixed solution of ethanol and hydroch...

Embodiment 3

[0060] Example 3: At 50°C, 2.00g polyethylene glycol 2000 was dissolved in 30g ethanol, and ultrasonicated for 2.0 hours (ultrasonic power 400W); 1.98g gamma-diethylenetriaminopropylmethyldimethoxysilane was dissolved In 40g of ethanol, under the condition that the stirring speed is 500 rpm, add 1.38g of zinc nitrate, dropwise add 2.88g of a mass concentration of 10% tetramethylammonium hydroxide aqueous solution, adjust with 10mol / L hydrochloric acid solution The pH value of the system was 13.5, and it was stirred for 2 hours. The above two solutions were mixed, and 7.85 g of propyl orthosilicate was added dropwise under the condition of an ultrasonic power of 400 W. After 2 hours, the prepared silica sol was placed in a constant temperature and humidity chamber until the solvent evaporated completely (humidity 25% RH, temperature 30° C.). The product was hydrothermally crystallized at 110°C for 2 days, and then the product and acidic ethanol mixture was extracted with micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com