Ceramic paint used on surface of steel and preparing method thereof

A technology for steel surface and ceramic coating, applied in the field of materials science, can solve the problems of low bonding force between ceramic coating and metal substrate, can not meet the anti-corrosion requirements of the heating surface of power plant boilers, etc., achieves low cost, high temperature molten salt corrosion inhibition, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The concrete steps of the method for preparing metal-based ceramic coating by thermochemical reaction of the present invention are as follows:

[0028] (1) Preparation of coating slurry:

[0029] Add sodium hydroxymethylcellulose into the deionized water, the specific ratio is 2-3g / L, then stir and heat to form a paste;

[0030] Put the ceramic aggregate in a certain proportion (mass fraction: 25% silica, 25% alumina, 10% titanium dioxide, 40% kaolin) into a ball mill jar and mill at 500r / min for 2-4h; then according to the weight percentage, mix 50 % ceramic aggregate, 2% tungsten carbide, 30% sodium silicate, and 4% sodium carbonate are mixed evenly, and the mixed powder is put into 14% prepared sodium hydroxymethyl cellulose aqueous solution. The mass of sodium hydroxymethyl cellulose accounts for 3% of the total mass of the paint, after stirring and aging for 24 hours, the mixed slurry was obtained;

[0031] (2) Coat the slurry prepared in step (1) evenly on the p...

Embodiment 2

[0033] The concrete steps of the method for preparing metal-based ceramic coating by thermochemical reaction of the present invention are as follows:

[0034] (1) Preparation of coating slurry:

[0035] Add sodium hydroxymethylcellulose into the deionized water, the specific ratio is 8g / L, then stir and heat to form a paste;

[0036] Put the ceramic aggregate in a certain proportion (mass fraction: 20% silica, 20% alumina, 20% titanium dioxide, 40% kaolin) into a ball mill jar and mill at 500r / min for 2-4h; then according to the weight percentage, mix 50 % ceramic aggregate, 5% tungsten carbide, 25% sodium silicate, and 5% sodium carbonate are mixed evenly, and the mixed powder is put into 15% prepared sodium hydroxymethyl cellulose aqueous solution, and the mass of sodium hydroxymethyl cellulose accounts for 5% of the total mass of the paint, after stirring and aging for 24 hours, the mixed slurry was obtained;

[0037] (2) Coat the slurry prepared in step (1) evenly on the...

Embodiment 3

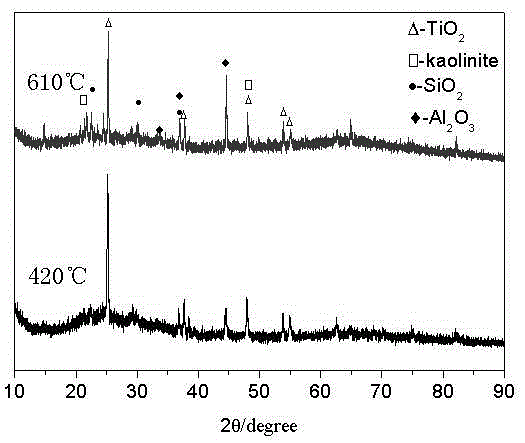

[0039] Prepared coating 1 and coating 2 are carried out XRD phase analysis, the results are shown in figure 2 . Depend on figure 2 It can be seen that TiO exists in the coatings fired at 420 °C and 610 °C. 2 , Kaolin, SiO 2 and Al 2 o 3 and other phases, and the amorphous "steamed bread peak" appeared in the range of 20-30°, indicating that there is a CMS glass phase (CaO+MgO+SiO 2 )generate. With the increase of temperature, the "mantou peak" gradually disappeared, and the peaks corresponding to each substance became sharper, but no new phase was formed obviously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com