Coked crude phenol refining device and method

A technology of coking crude phenol and refining equipment, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as lack of technological advancement and practicability, inability to stabilize distillation, and increased energy consumption of distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

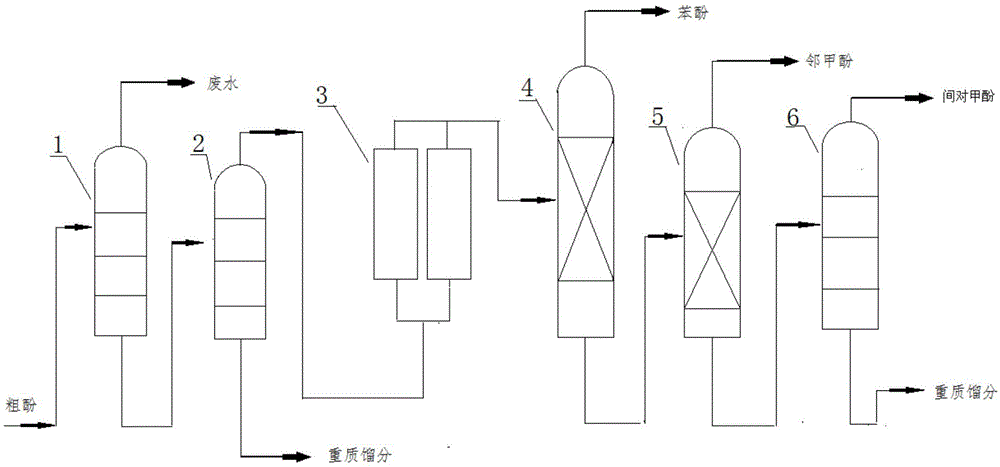

Image

Examples

Embodiment 1

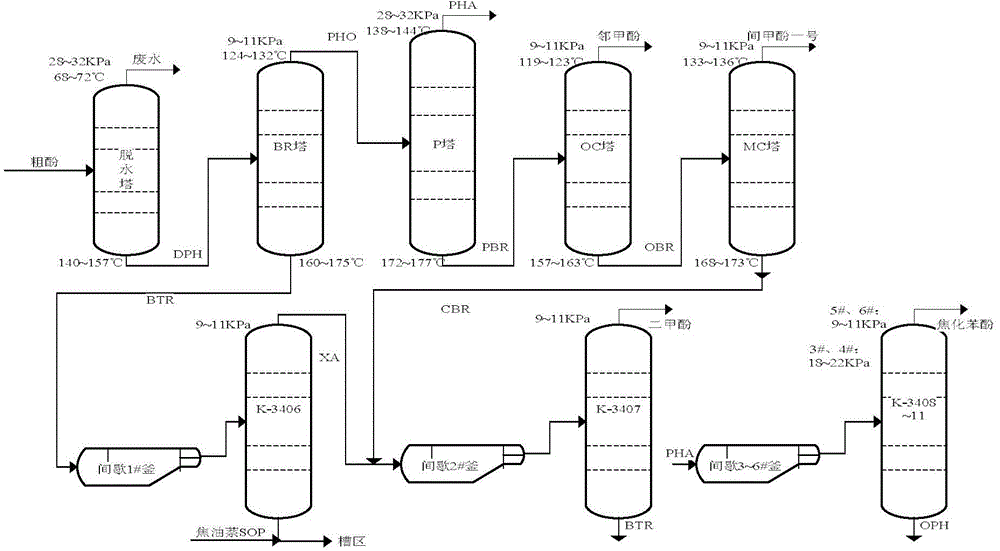

[0070] For the raw material liquid of a certain coking crude phenol, the flow rate is 1200l / h into the dehydration tower for dehydration, the water is separated from the top of the tower to 216l / h, the crude phenol from the bottom of the tower enters the de-weighting tower, and the phenol fraction produced at the top of the tower is 1039l / h h, into the phenol fraction tank T-3430. 900 l / h of the phenol fraction through dehydration and weight removal enters the adsorption reaction tower equipped with a mercaptan catalyst, and enters the phenol tower after leaving the tower. Cresol etc. 6.71%.

[0071] The operating conditions of the dehydration tower 1 are: the operating pressure at the top of the tower is 29.67KPa, the reflux ratio is 1.0, the temperature at the top of the tower is 71.6°C, and the temperature at the bottom of the tower is 145.5°C. The operating conditions of the weight removal tower 2 are as follows: the operating pressure at the top of the tower is 11.1KPa, ...

Embodiment 2

[0074] For a raw material solution of coking crude phenol, the flow rate is 999.6l / h into the dehydration tower for dehydration, and the water is separated from the top of the tower to 195.9l / h. The crude phenol from the bottom of the tower enters the de-weighting tower, and the phenol fraction is produced at the top of the tower 867.2l / h, into the phenol fraction tank T-3430. The 899.4l / h phenol fraction through dehydration and weight removal enters the adsorption reaction tower equipped with a sweetening catalyst, and enters the phenol tower after leaving the tower. It is composed of phenol 50.64%, o-cresol 11.15%, m-p-cresol 29.74%, di Cresol etc. 7.14%.

[0075] The operating conditions of the dehydration tower 1 are: the operating pressure at the top of the tower is 29.24KPa, the reflux ratio is 1.0, the temperature at the top of the tower is 69.51°C, and the temperature at the bottom of the tower is 149.38°C. The operating conditions of the weight removal tower 2 are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com