The preparation method of colorless fatty alkyl amphoteric sodium acetate

A technology of aliphatic alkyl and sodium acetate, which is used in the preparation of carboxylic acid amides, the preparation of organic compounds, preparations for skin care, etc. and other problems, to achieve the effect of less steps, low production cost and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

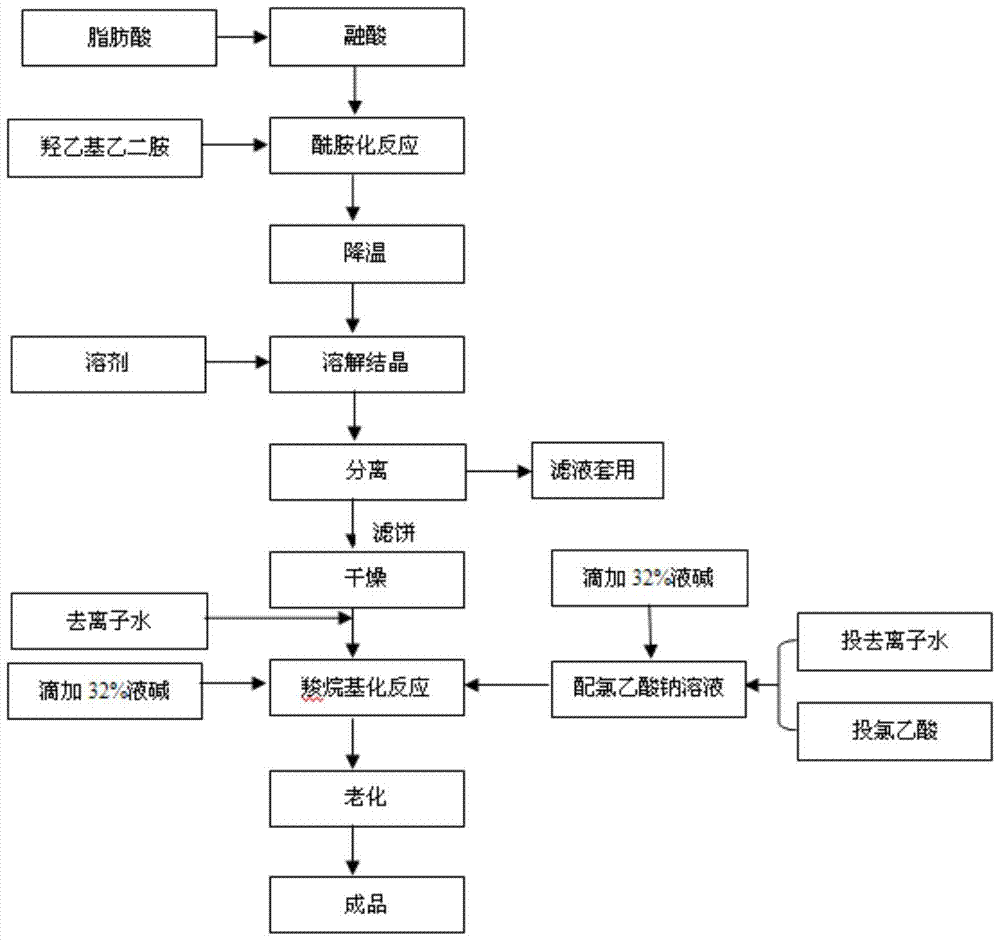

Method used

Image

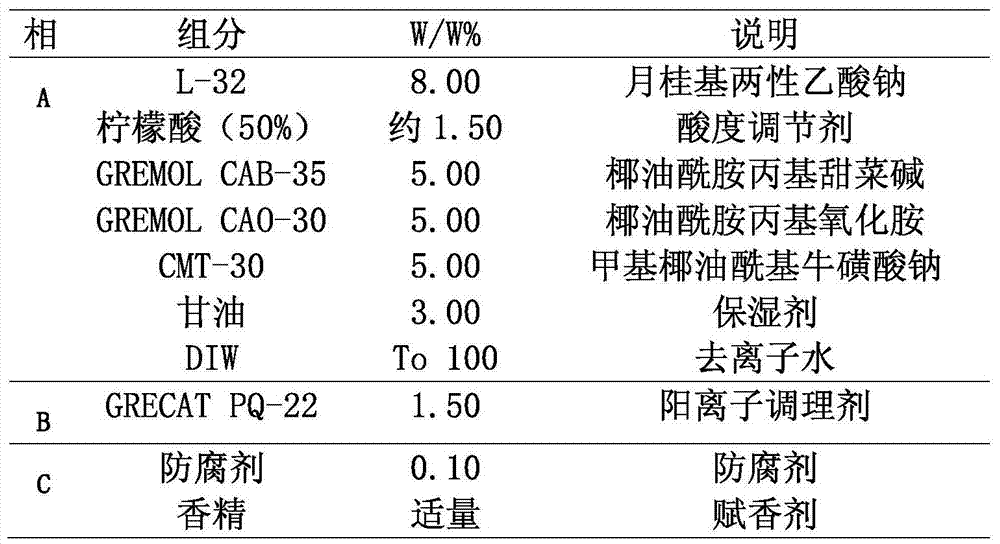

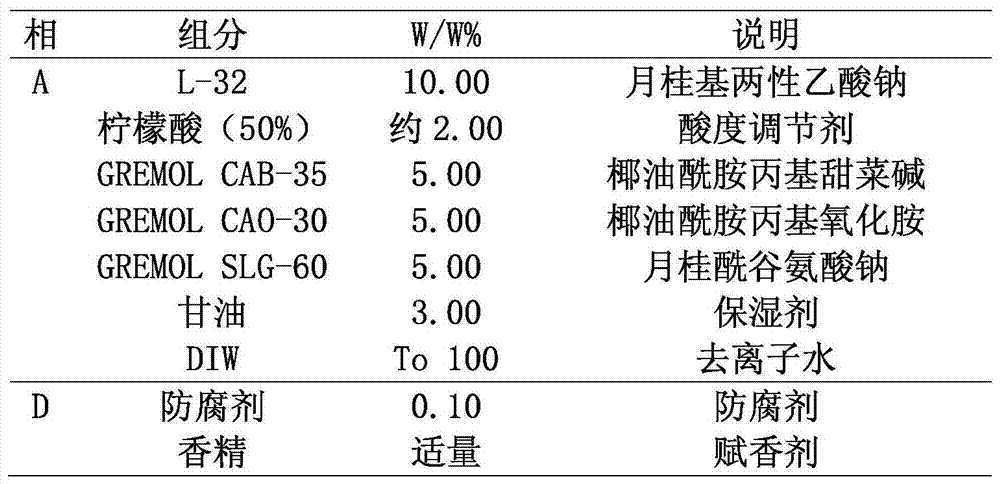

Examples

Embodiment 1

[0024] a) Amidation reaction: put in 100g (0.5mol) of lauric acid, slowly heat up to 80°C to melt the acid, after the acid melt is complete, turn on nitrogen at 40L / h, add 54.71g of hydroxyethylethylenediamine, and heat up to 150°C within 4h ℃, turn on the vacuum, control the vacuum degree from 0MPa to -0.08MPa within 2h, and keep the reaction at this temperature and vacuum degree for 5-6h;

[0025] b) Preparation of intermediate: cooling the prepared amide to 50°C, adding 300g of absolute ethanol, stirring to dissolve, stirring at 50r / min, keeping the cooling rate at 2-3°C / h to 4°C, and maintaining crystallization for 24h, Obvious crystals can be observed through a microscope, vacuum filtration to obtain 134.21g filter cake, and then the resulting filter cake is vacuum-dried at 80°C to obtain 128.84g intermediate, and the residual bisamide is determined to be 0.15% (wt, ion exchange method);

[0026] c) Preparation of colorless fatty alkyl amphoteric sodium acetate: add 175.1...

Embodiment 2

[0031] a) Amidation reaction: put in 100g (0.5mol) of lauric acid and 28.5g of myristic acid, slowly heat up to 80°C to melt the acid, after the acid melt is complete, turn on nitrogen at 60L / h, add 162.74g of hydroxyethylethylenediamine, Raise the temperature to 150°C within 3 hours, turn on the vacuum, and control the vacuum degree from -0.06MPa to -0.08MPa within 3 hours. At this temperature and vacuum degree, keep the reaction for 4 hours to obtain the amide;

[0032] b) Preparation of intermediate: cooling the prepared amide to 60°C, adding 1000g of isopropanol, stirring to dissolve, stirring at 50r / min, keeping the cooling rate at 2-3°C / h to 10°C, and maintaining crystallization for 48h, Obvious crystals can be observed through a microscope, and 183.55 g of filter cakes are obtained by vacuum suction filtration, and 170.35 g of intermediates are obtained by vacuum drying at 90° C., and the residual bisamide is determined to be 0.11% (wt, ion exchange method);

[0033] c)...

Embodiment 3

[0038] a) Amidation reaction: put in 110g (0.5mol) coconut oil, slowly heat up to 80°C to melt the acid, after the acid melt is complete, turn on nitrogen gas at 100L / h, add 156.20g of hydroxyethylethylenediamine, and heat up to 80°C within 6h 150°C, turn on the vacuum, control the vacuum degree from -0.04MPa to -0.08MPa within 2 hours, and keep the reaction for 3-4 hours at this temperature and vacuum degree to obtain the amide;

[0039] b) Preparation of intermediate: Cool the prepared amide to 55°C, add 500g of acetone, stir to dissolve, keep stirring at 50r / min, keep the cooling rate at 2-3°C / h to 4°C, keep crystallization for 6h, and pass through the microscope Obvious crystals can be observed, vacuum suction filtration to obtain 145.07g filter cake, vacuum drying at 80°C to obtain 142.17g intermediate, and the residual bisamide was determined to be 0.21% (wt, ion exchange method);

[0040] c) Preparation of colorless fatty alkyl amphoteric sodium acetate: add 191.13 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com