Lithium ion battery negative electrode composite film material and preparation method thereof

A lithium-ion battery and composite thin film technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that hinder the development of industrialization, high irreversible capacity, and poor cycle stability, and achieve a good collector contact interface and high magnification , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

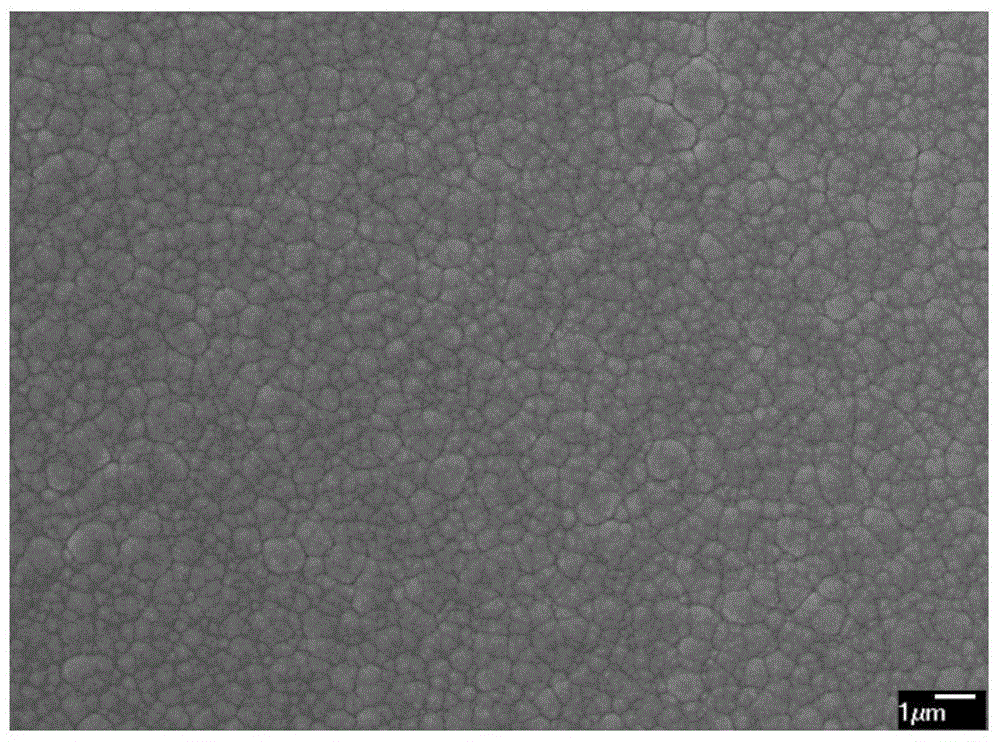

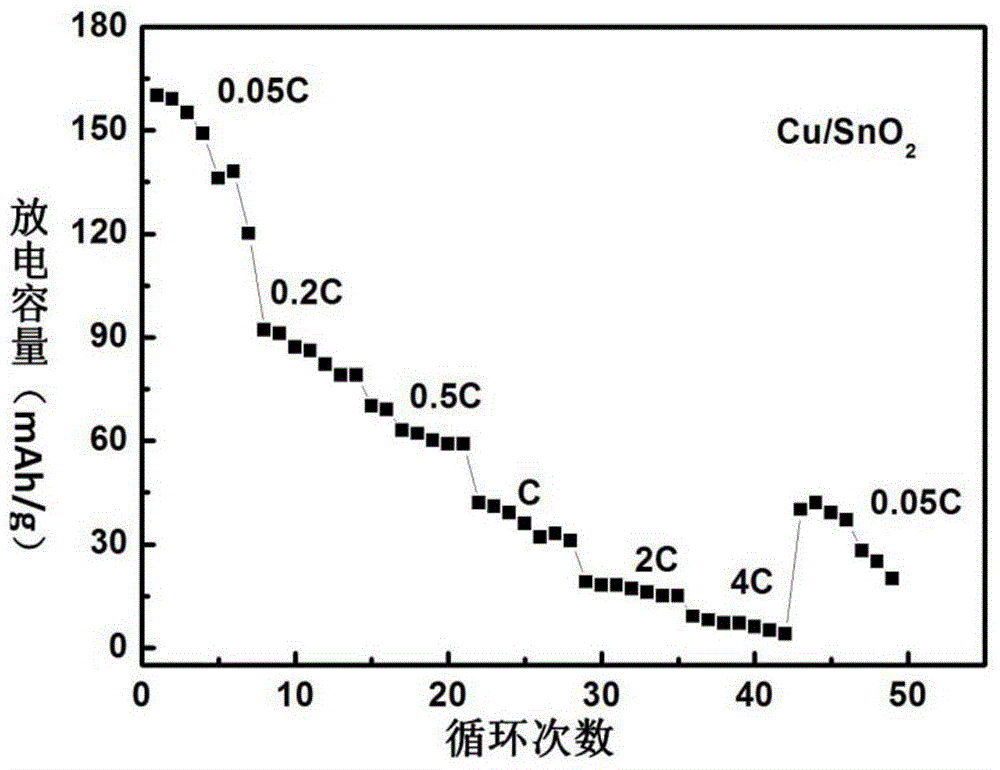

[0027] Example 1: Soak the copper foil cleaned by ultrasonic waves in acetic acid for 3 hours to remove surface oxides, and move into ceramic targets containing ZnO and SnO 2 On the substrate base of the vacuum chamber of the radio frequency magnetron sputtering equipment, vacuumize to a pressure of 5×10 -4 Pa, feed argon as the sputtering gas, adjust the gas flow to 20sccm, adjust the working pressure to 0.75Pa, carry out the sputtering deposition of the ZnO intermediate layer, the sputtering power is 40W, the deposition time is 5min, and then rotate the substrate base to SnO 2 target site, for SnO 2 Thin film deposition, the electron beam current is 80mA, the deposition time is 20min, and the ZnO / SnO prepared on the copper current collector substrate is obtained. 2 Composite films such as figure 1 is the surface microstructure morphology of Cu foil. Cut the obtained composite film into 0.8×0.8cm 2 The electrode sheet to LiPF 6 As the electrolyte, the lithium sheet is u...

Embodiment 2

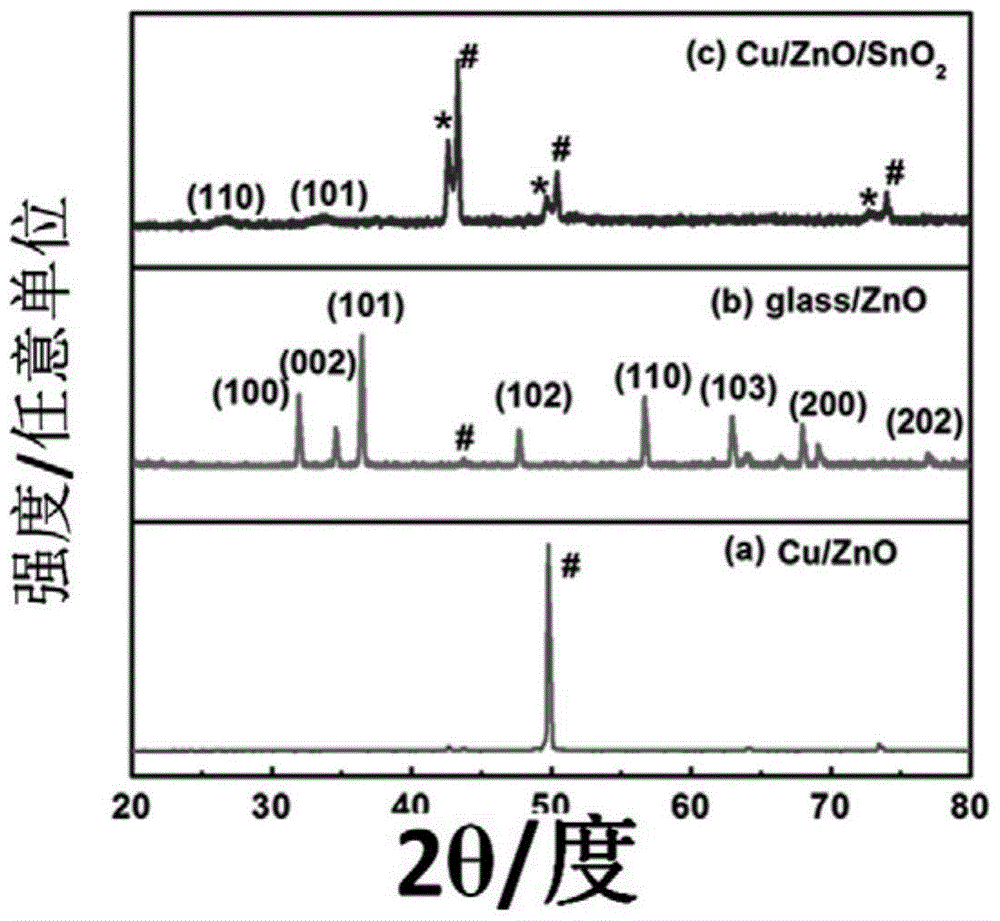

[0028] Embodiment 2: Put the ultrasonically cleaned copper foil into dilute hydrochloric acid and soak for 5 minutes to remove surface oxides, move it into the vacuum chamber substrate base of the radio frequency magnetron sputtering equipment with ceramic target ZnO, and evacuate to pressure 5×10 -4 Pa, feed argon as the sputtering gas, adjust the gas flow rate to 20sccm, adjust the working pressure to 0.75Pa, carry out the sputtering deposition of the ZnO interlayer, the sputtering power is 40W, the deposition temperature is 300 ° C, the deposition time is 5min, and then After cooling to room temperature, take it out and move it into the deposition chamber of the electron beam evaporator for evaporation of SnO 2 Thin film, the adjustment voltage is 6kV, the electron beam current is 150mA, and the room temperature is deposited for 30min to obtain the ZnO / SnO prepared on the copper current collector substrate. 2 composite film, figure 2 ZnO, glass / ZnO deposited by sputterin...

Embodiment 3

[0029] Example 3: Soak the ultrasonically cleaned copper foil in dilute hydrochloric acid for 5 minutes to remove surface oxides, and move into metal-containing copper targets, ceramic targets ZnO and SnO 2 On the substrate base of the vacuum chamber of the DC / RF magnetron sputtering equipment, vacuumize to a pressure of 5×10 -4 Pa, feed argon as the sputtering gas, adjust the gas flow rate to 20sccm, adjust the working pressure to 1.5Pa, firstly carry out the sputtering of the copper film buffer layer, the sputtering time is 3 minutes, and then carry out the sputtering deposition of the ZnO intermediate layer , the sputtering power was 40W, the deposition time was 5min, and then the substrate pedestal was rotated to the SnO 2 target site, for SnO 2 Thin film deposition, the sputtering power is 80W, the deposition time is 20min, and the Cu / ZnO / SnO prepared on the copper current collector substrate is obtained 2 Composite film. Cut the obtained composite film into 0.8×0.8cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com