A kind of diatom mud coating that adds amino acid to remove formaldehyde

A technology of diatom mud coating and amino acid is applied in the field of diatom mud coating and diatom mud coating adding amino acid to remove formaldehyde, which can solve the problems of reducing the concentration of indoor pollutants, inconvenient for long-term use, and crystallization will be precipitated. Good stability, simple formula, and the effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

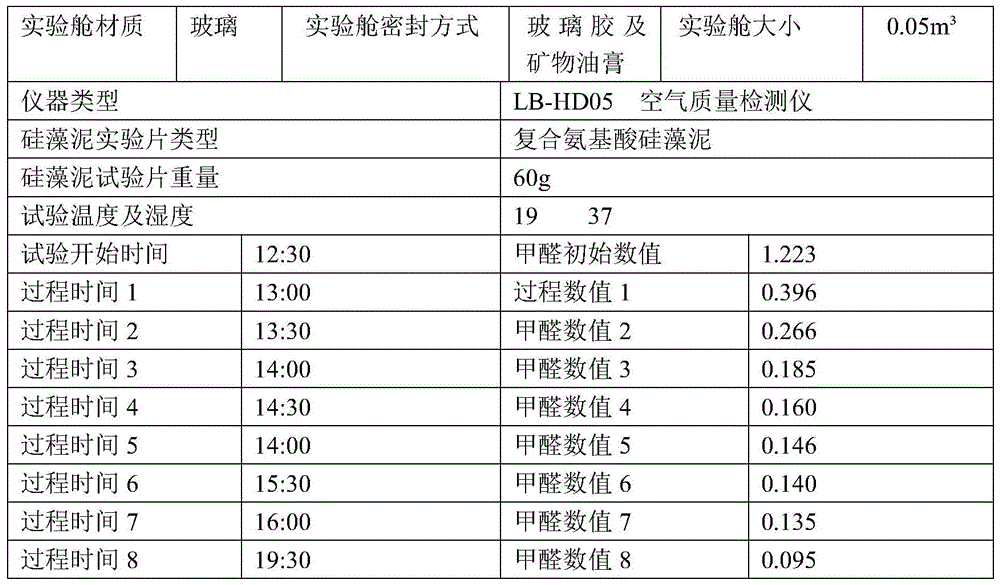

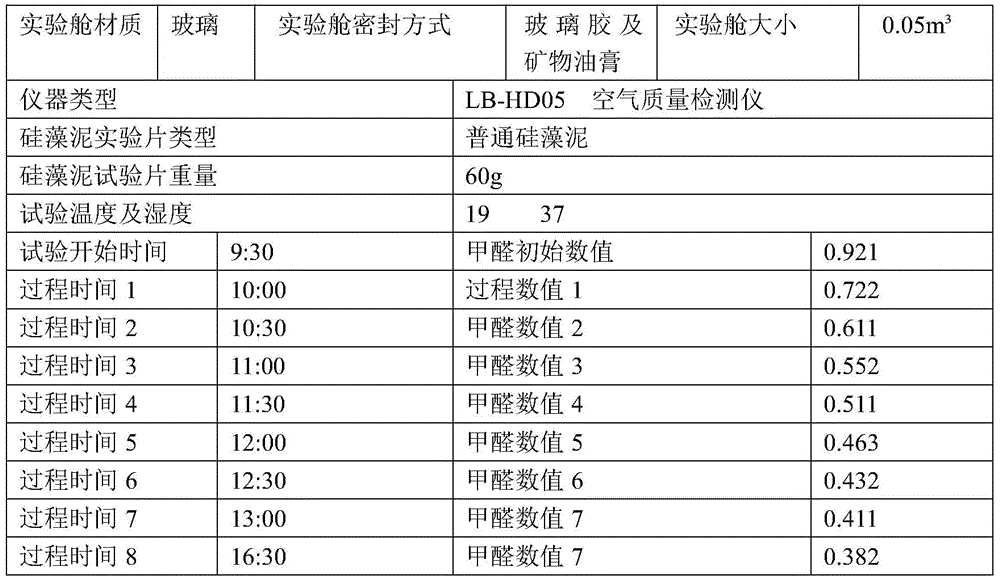

Examples

Embodiment 1

[0030] A kind of diatom mud coating that adds amino acid to remove formaldehyde, each component and quality are:

[0031] Compound amino acid diatomite 35kg, sepiolite 20kg, bentonite 5kg, attapulgite 5kg, cellulose ether 0.8kg, starch ether 6kg, quartz sand 20kg

[0032] The preparation method of compound amino acid diatomite is:

[0033] 1. Heat 1kg of water to 50°C and keep it warm

[0034] 2. Take 390g glycine and stir it into hot water to dissolve

[0035] 3. After stirring and dissolving, add 39g of sodium carbonate and continue stirring to dissolve, then add 0.1g of alkaline protease (from Taian Xindeli Bioengineering Co., Ltd.), keep it at 50°C for 3 hours, and then take the calcined first-grade silicon Alginate is added to the solution and the solution is sucked up

[0036] 4. Dry the diatomite inhaled with glycine or put it in an oven for drying. The oven temperature is 100-200°C, which is lower than the melting point of glycine at 248°C to avoid its decomposition...

Embodiment 2

[0039] A kind of diatom mud coating that adds amino acid to remove formaldehyde, each component and quality are:

[0040] Compound amino acid diatomite 35kg, diatomite (calcined first grade) 5kg, sepiolite 25kg, bentonite 1kg, attapulgite 6kg, negative ion powder 1kg, cellulose ether 1kg, starch ether 8kg

Embodiment 3

[0042] A kind of diatom mud coating that adds amino acid to remove formaldehyde, each component and quality are:

[0043] Compound amino acid diatomite 20kg, diatomite (calcined first grade) 5kg, sepiolite 20kg, bentonite 1kg, attapulgite 5kg, cellulose ether 0.8kg, starch ether 6kg, quartz sand 20kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com