Isoborneol-dehydrogenated camphor refining method and equipment therefor

A technology of isoborneol and camphor, which is applied in the direction of dehydrogenation preparation, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems that basic copper carbonate cannot be recycled, the product quality is unstable, and the production efficiency is low. The effect of good dosage, saving process and reducing the production of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

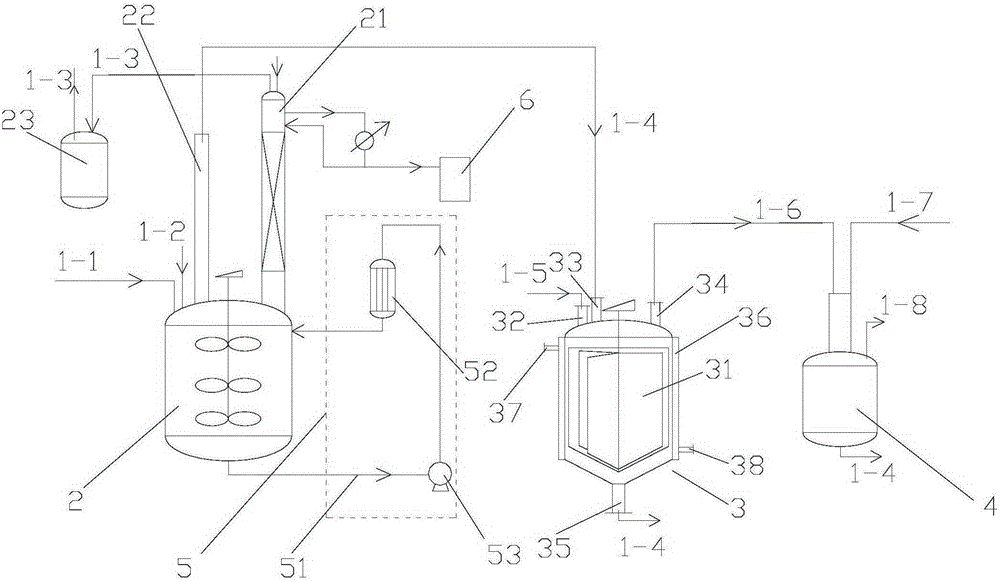

[0052] A method for purifying camphor by isoborneol dehydrogenation, comprising steps of dehydrogenation reaction and solvent recovery, camphor vaporization sublimation step and camphor sublimation collection step;

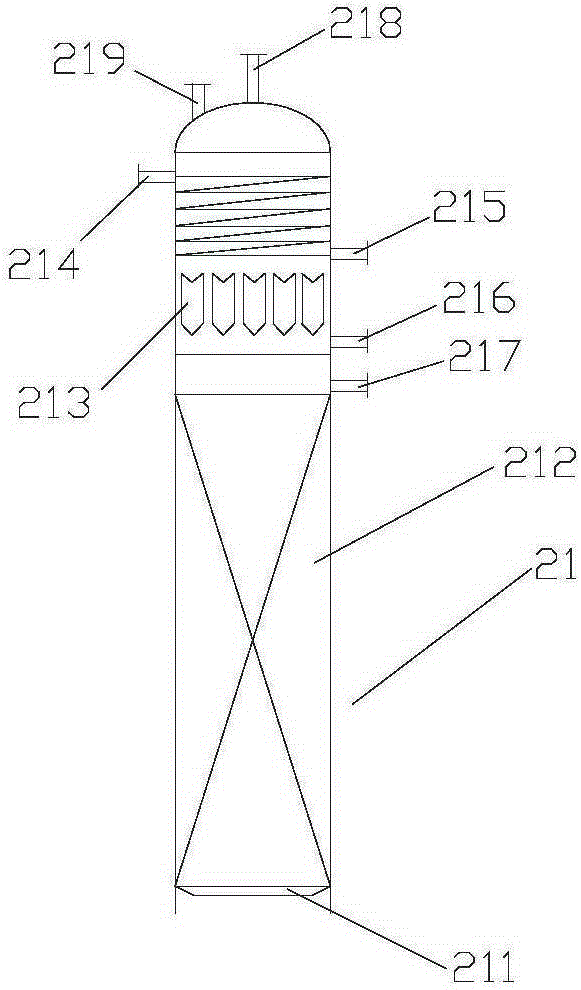

[0053] The dehydrogenation reaction and the solvent recovery step are to send the mixed solution 1-1 of isoborneol and p-cymene and the palladium carbon catalyst 1-2 into the reactor 2, and the mass ratio of isoborneol and palladium carbon catalyst is 1:0.02. Heating the reaction kettle 2 to realize the dehydrogenation reaction, controlling the temperature between 185°C, using the fractionating column 21 to discharge the hydrogen gas 1-3 generated by the dehydrogenation reaction, and recovering the isoborneol dissolved solvent;

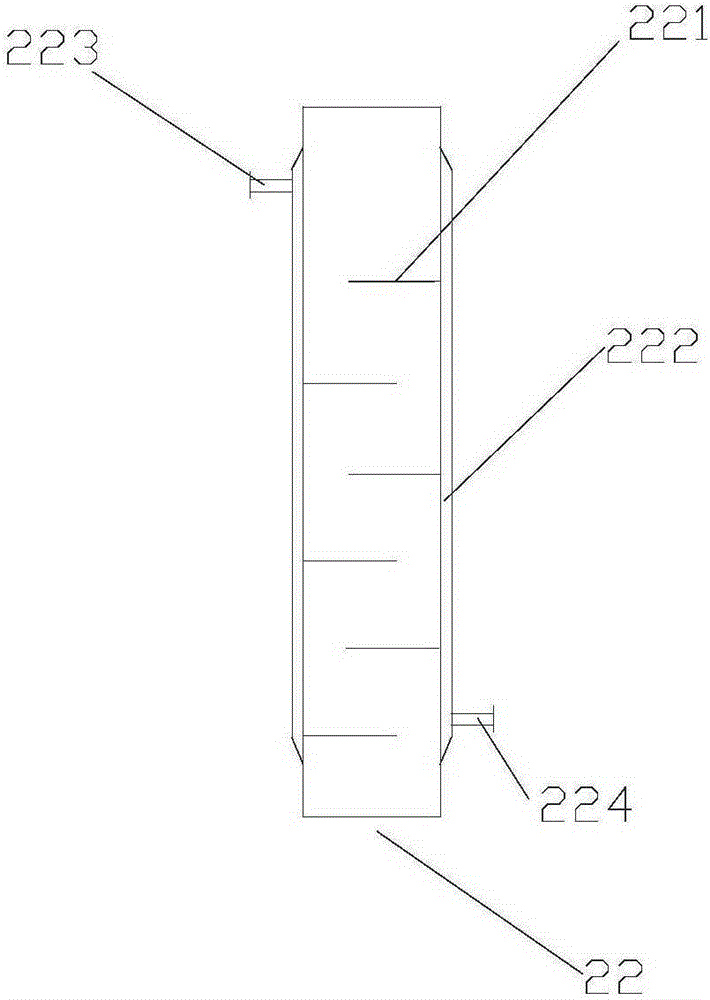

[0054] The camphor vaporization and sublimation step is to further heat up and heat the remaining materials in the reactor 1 after the dehydrogenation reaction and the solution recovery step to 190°C through the vaporization column 22, so...

Embodiment 2

[0059] A method for purifying camphor by isoborneol dehydrogenation, comprising steps of dehydrogenation reaction and solvent recovery, camphor vaporization sublimation step and camphor sublimation collection step;

[0060] The dehydrogenation reaction and the solvent recovery step are to send the mixed solution 1-1 of isoborneol and p-cymene and the palladium carbon catalyst 1-2 into the reactor 2, and the mass ratio of isoborneol and palladium carbon catalyst is 1:0.03. Heating the reaction kettle 2 to realize the dehydrogenation reaction, controlling the temperature between 172°C, using the fractionating column 21 to discharge the hydrogen gas 1-3 generated by the dehydrogenation reaction, and recovering the isoborneol dissolved solvent;

[0061] The camphor vaporization and sublimation step is to use the vaporization column 22 to further heat up and heat the remaining materials in the reactor 1 after the dehydrogenation reaction and the solution recovery step to between 20...

Embodiment 3

[0066] A method for purifying camphor by isoborneol dehydrogenation, comprising steps of dehydrogenation reaction and solvent recovery, camphor vaporization sublimation step and camphor sublimation collection step;

[0067] The dehydrogenation reaction and the solvent recovery step are to send the mixed solution 1-1 of isoborneol and p-cymene and the palladium carbon catalyst 1-2 into the reactor 2, and the mass ratio of isoborneol and palladium carbon catalyst is 1:0.04. Heating the reaction kettle 2 to realize the dehydrogenation reaction, controlling the temperature between 160°C, using the fractionating column 21 to discharge the hydrogen gas 1-3 generated by the dehydrogenation reaction, and recovering the isoborneol dissolved solvent;

[0068] The camphor vaporization and sublimation step is to use the vaporization column 22 to further heat up and heat the remaining materials in the reactor 1 after the dehydrogenation reaction and the solution recovery step to between 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com