Aluminum oxide-gallium oxide mixed-crystal material for wide-band-gap semiconductors

A wide bandgap semiconductor, alumina technology, applied in the growth of polycrystalline materials, single crystal growth, inorganic chemistry and other directions, can solve the problems of low doping concentration, poor material quality, difficult growth technology, etc., to achieve uniform color, High optical quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

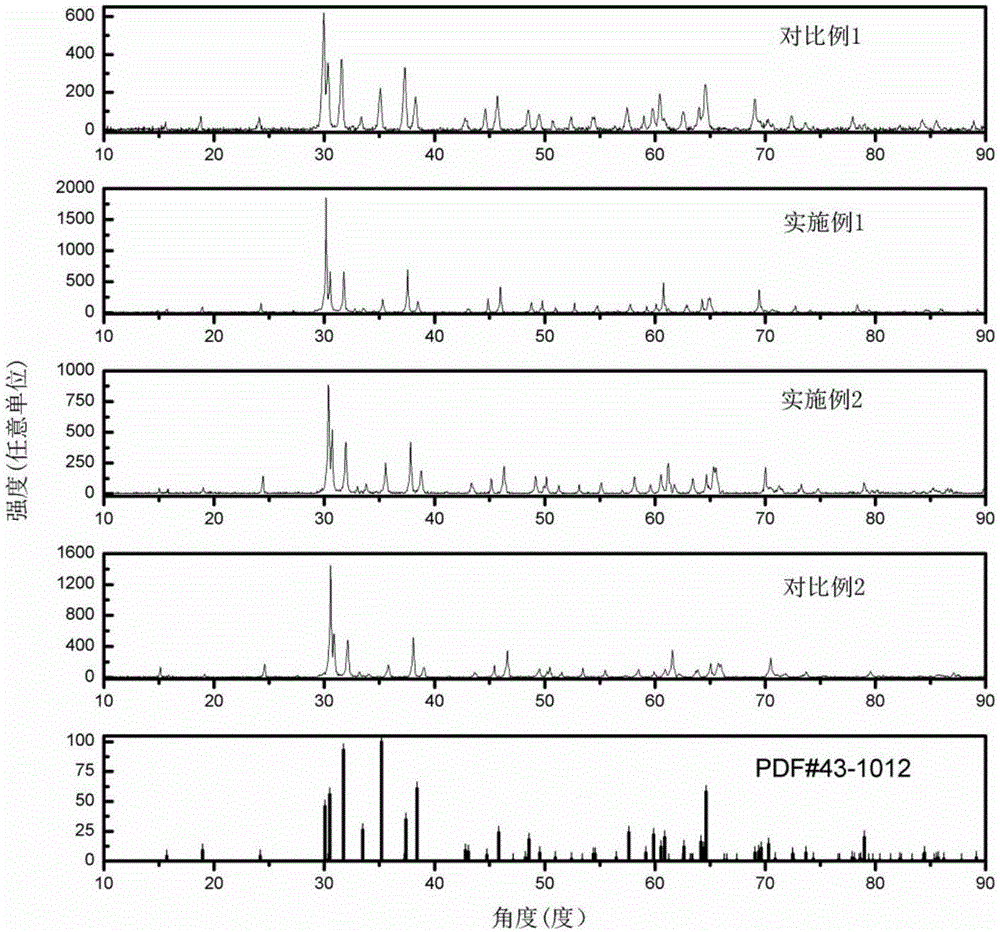

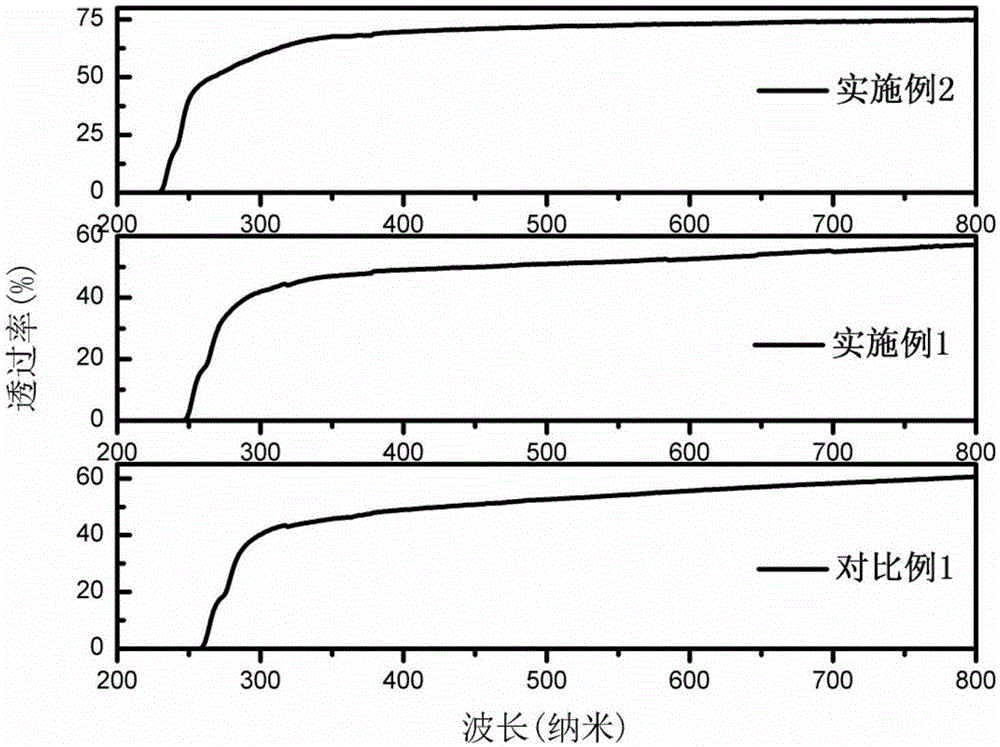

Embodiment 1

[0029] The aluminum oxide-gallium oxide mixed crystal material is grown by using the above-mentioned raw material ratio and process flow, and x=0.1 is taken in the raw material ratio. Ga 2 o 3 , Al 2 o 3 High-purity raw materials (all with a purity of 99.999%) are weighed in a molar ratio of 0.9:0.1. The raw materials were mixed evenly by ethanol wet ball milling for 16 hours, baked in an oven at 100°C for 6 hours, pressed into a rod with an organic elastic plastic mold in an isostatic press, and sintered in a muffle furnace at 1500°C for 10 hours. Put the sintered material rod into the floating zone furnace as the upper rod, and the gallium oxide seed crystal as the lower rod. The temperature rises to melt and inoculate the seed crystals, starting crystal growth. The crystal growth rate was 5 mm / h, the rotation rate was 10 rpm, and the atmosphere was air. After the crystal growth was completed, the melting zone was pulled off, and the temperature was slowly lowered to r...

Embodiment 2

[0031] The aluminum oxide-gallium oxide mixed crystal material is grown by using the above-mentioned raw material ratio and process flow, and x=0.3 is taken in the raw material ratio. Ga 2 o 3 , Al 2 o 3 High-purity raw materials (all with a purity of 99.999%) are weighed in a molar ratio of 0.7:0.3. The raw materials were mixed evenly by ethanol wet ball milling for 18 hours, baked in an oven at 70°C for 10 hours, pressed into a rod with an organic elastic plastic mold in an isostatic press, and sintered in a muffle furnace at 1500°C for 10 hours. Put the sintered material rod into the floating zone furnace as the upper rod, and the gallium oxide seed crystal as the lower rod. The temperature rises to melt and inoculate the seed crystals, starting crystal growth. The crystal growth rate was 4 mm / h, the rotation rate was 12 rpm, and the atmosphere was air. After the crystal growth was completed, the melting zone was pulled off, and the temperature was slowly lowered to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com