Novel composite fiber based on sweet sorghum skin fiber and preparation method thereof

A composite fiber, sweet sorghum technology, applied in the chemical characteristics of fibers, cellulose/protein conjugated rayon, wet spinning, etc., can solve the problems of simple preparation of finished products, limited economic value, backwardness, etc., and achieve improved functionality. , the effect of enhancing mechanical strength and improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

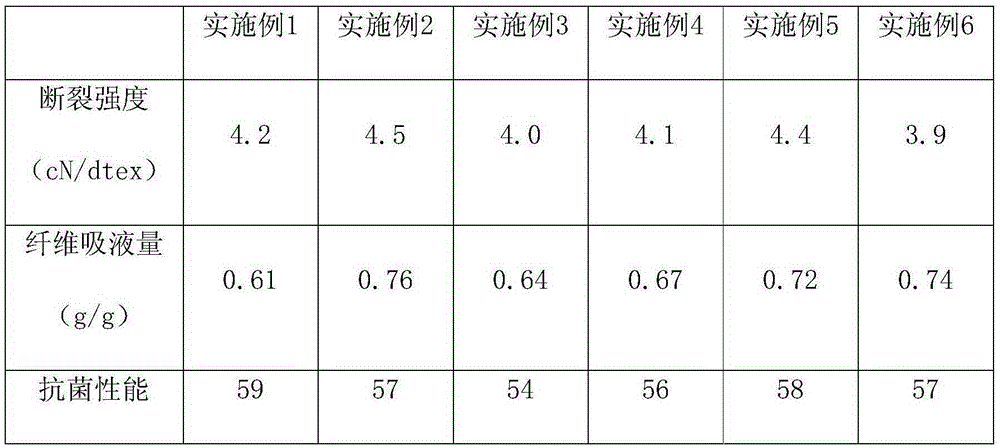

Examples

Embodiment 1

[0031] (1) Remove the leaves and wash the sweet sorghum stalks with a length of about 15 cm, and obtain the sweet sorghum husk and meat marrow containing the original juice through a separator, squeeze and separate the meat marrow containing the original juice to obtain the stalk meat dregs, and separate the stalks The meat dregs were washed, dried in the sun, crushed and filtered to obtain 200-mesh stem dregs powder.

[0032] (2) The sweet sorghum husk prepared in step (1) is thinned into husk fiber strips with a width of 0.1 cm, and the husk fiber strips are ultrasonically dispersed in an aqueous solution, washed and dried to obtain 2 cm long husk fibers.

[0033] (3) In parts by weight, mix 25 parts of the stalk powder prepared in step (1) and 60 parts of the sheath fiber prepared in step (2) evenly, add distilled water at 60°C to swell for 2 hours, and then add 5 parts of the shell The polysaccharide and 20 parts of sodium alginate were stirred at high temperature and high...

Embodiment 2

[0036] (1) Remove the leaves and wash the sweet sorghum stalks about 20cm long, and use a separator to obtain the sweet sorghum husk and meat marrow containing the original juice, press and separate the meat marrow containing the original juice to obtain the stalk meat dregs, and separate the stalks The meat dregs were washed, dried in the sun, crushed and filtered to obtain 300-mesh stem dregs powder.

[0037] (2) Thinning the sweet sorghum cortex prepared in step (1) into a cortex fiber strip with a width of 0.2 cm, placing the cortex fiber strip in 50% ethanol aqueous solution to ultrasonically disperse, wash, and dry to obtain a 5 cm long strip. sheath fibers.

[0038] (3) In parts by weight, mix 30 parts of the stem residue powder prepared in step (1) and 80 parts of the sheath fiber prepared in step (2) evenly, add 80°C distilled water to swell for 3 hours, and then add 10 parts of the shell The polysaccharide and 40 parts of sodium alginate were stirred at high tempera...

Embodiment 3

[0041] (1) Remove the leaves and wash the sweet sorghum stalks with a length of about 18 cm, and obtain the sweet sorghum husk and meat marrow containing the original juice through a separator, press and separate the meat marrow containing the original juice to obtain the stalk meat dregs, and separate the stalks The meat dregs were washed, dried in the sun, crushed and filtered to obtain 250-mesh stem dregs powder.

[0042](2) The sweet sorghum cortex prepared in step (1) is thinned into a cortex fiber strip with a width of 0.15 cm, and the cortex fiber strip is placed in 25% ethanol aqueous solution to ultrasonically disperse, wash, and dry to obtain a length of 4 cm. sheath fiber.

[0043] (3) In parts by weight, mix 27 parts of the stalk powder prepared in step (1) and 70 parts of the sheath fiber prepared in step (2), and add 70 parts of distilled water to swell for 2.5 hours, then add 7 parts of Chitosan and 30 parts of sodium alginate were stirred at high temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com