Application of employing N and Mo for improving temperature-sensitive characteristics of oxidized graphene

A graphene and temperature-sensitive technology, which is applied to thermometers, thermometers, and electrical devices that use electrical/magnetic components that are directly sensitive to heat. It can solve the problems of small feedback signal current, increase measurement accuracy, and have wide adaptability. , the effect of reducing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

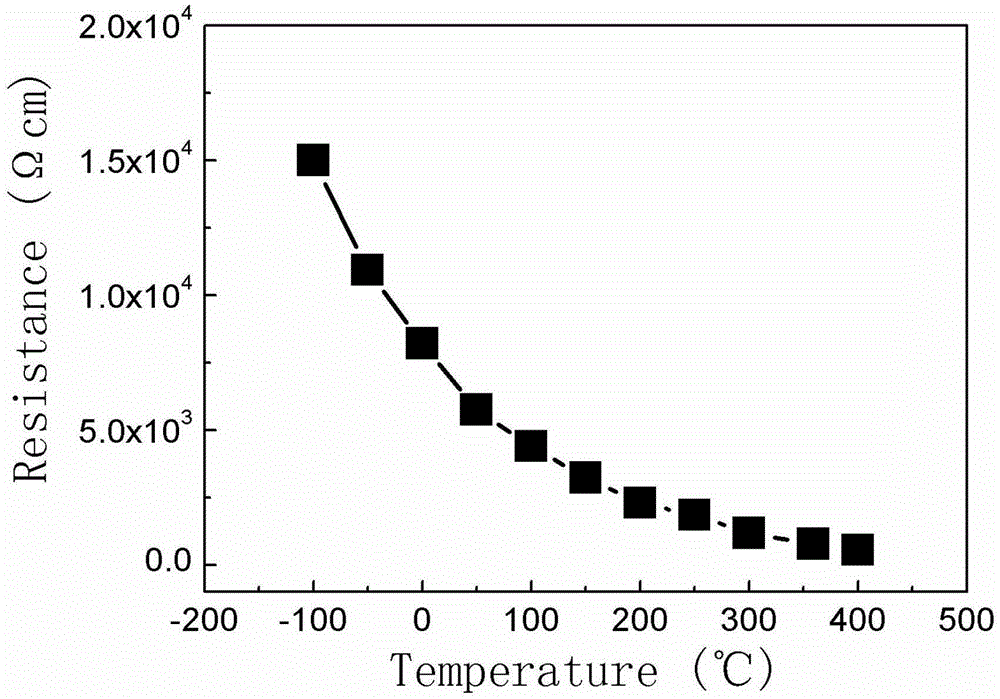

Embodiment 1

[0026] Step 1: Prepare doped graphene oxide powder. The steps are as follows: add 50g / L graphite powder and 20g / L potassium permanganate to 98% concentrated sulfuric acid to obtain a mixed solution. After stirring at 30 / 90 degrees Celsius for 1 hour each, adding 30% hydrogen peroxide with the same volume as the mixed solution, taking out the precipitate after standing for 5 days, ultrasonic treatment for 2 hours, centrifugal filtration and drying to obtain graphene oxide powder.

[0027] Step 2: Use NO 2 The gas doped graphene oxide with N, and the steps are as follows: Put the graphene oxide powder into a tube furnace, and place the graphene oxide powder at a pressure of 50Pa NO 2 After heating to 800°C in an atmosphere, the temperature is kept for 5 minutes, and then it is taken out after cooling to room temperature.

[0028] Step 3: Use MoCl 3 Doping graphene oxide with Mo, the steps are as follows: add MoCl 3 Dissolve in THF and prepare a solution with a molar concentration of 1...

Embodiment 2

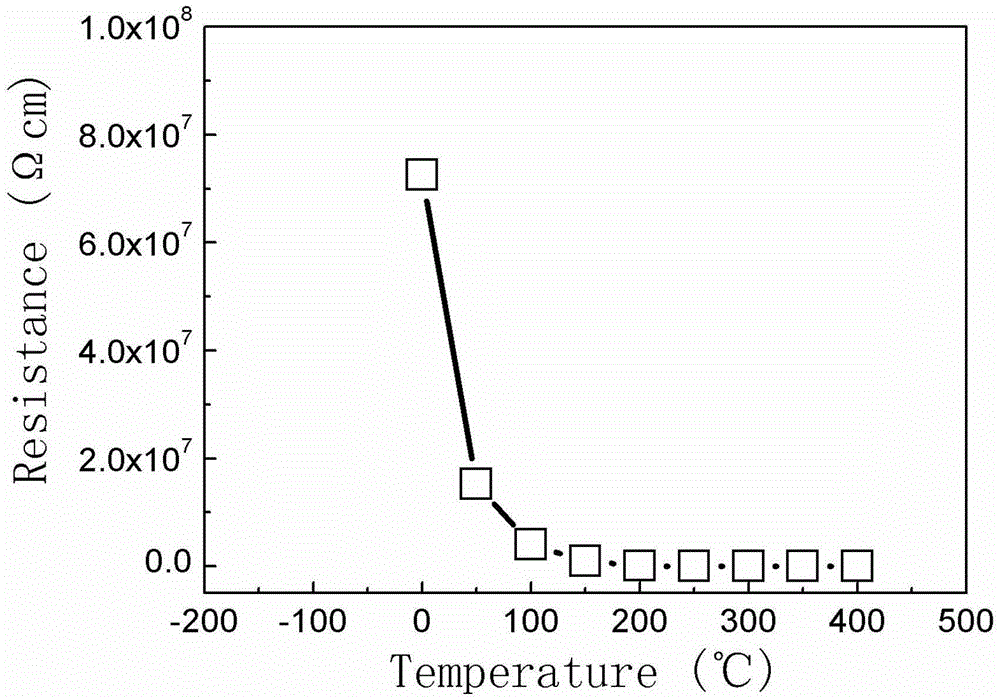

[0032] The preparation method and test are the same as in Example 1, but the doping link in step 2 and step 3 is omitted. figure 2 The resistivity measured at different temperatures for the graphene oxide block prepared in this embodiment is given in the section. It can be seen that the resistivity changes with the temperature, but the degree of nonlinearity is greater than that of Example 1. The resistivity rises extremely fast in the low temperature zone, and it is close to 10 at 0℃ 8 In the order of Ωcm, the resistivity in the high temperature zone does not change significantly, and the overall temperature sensitivity is worse than that of Example 1. Comparing Example 1 and Example 2, it can be seen that co-doping significantly improves the temperature sensitivity of graphene oxide.

Embodiment 3

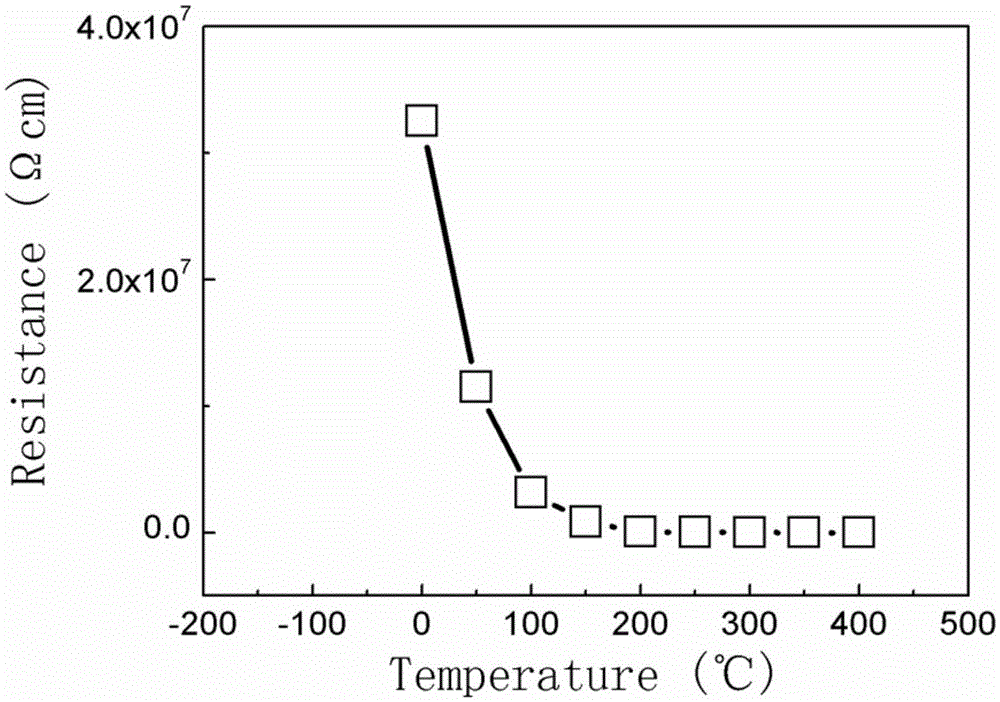

[0034] The preparation method and test are the same as in Example 1, but the doping link in step 2 is omitted. image 3 The resistivity measured at different temperatures of the graphene oxide block prepared in this implementation is given in. It can be seen that the resistivity changes with the temperature, but the degree of non-linearity is greater than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com