Preparation method and application of b-axial LiFePO<4>/C nano flake material

A nano-flaky, axial technology, applied in the electrical field, can solve the problems of poor rate performance of lithium batteries, and achieve the effect of good lithium extraction/insertion ability and uniform grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

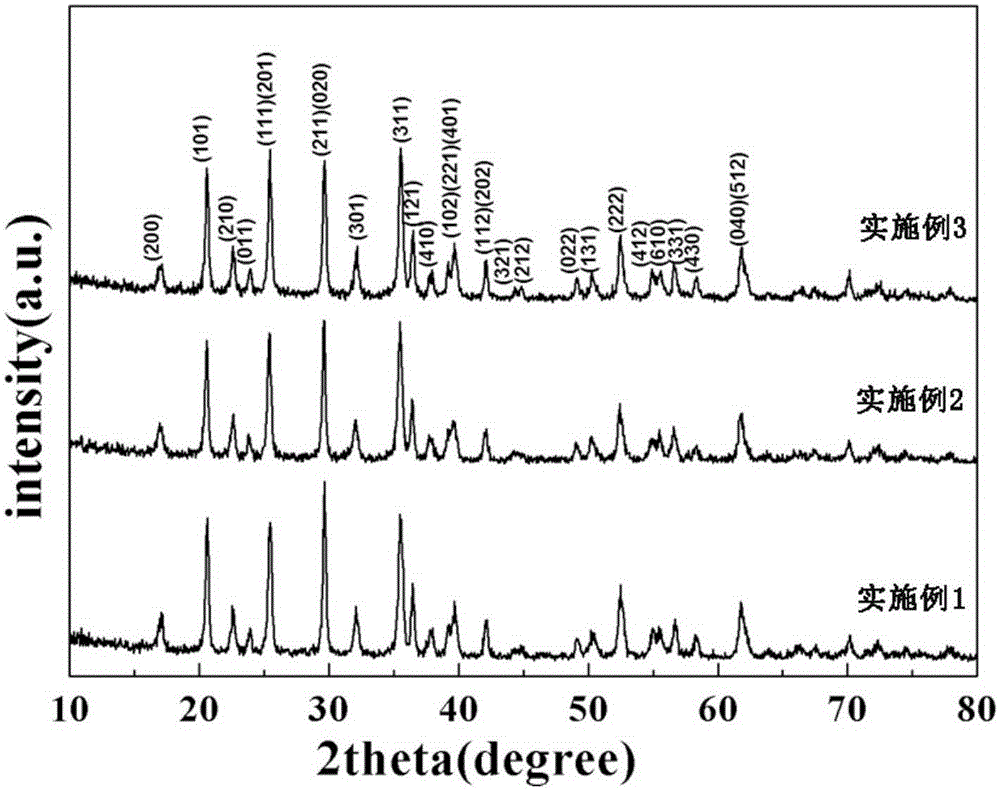

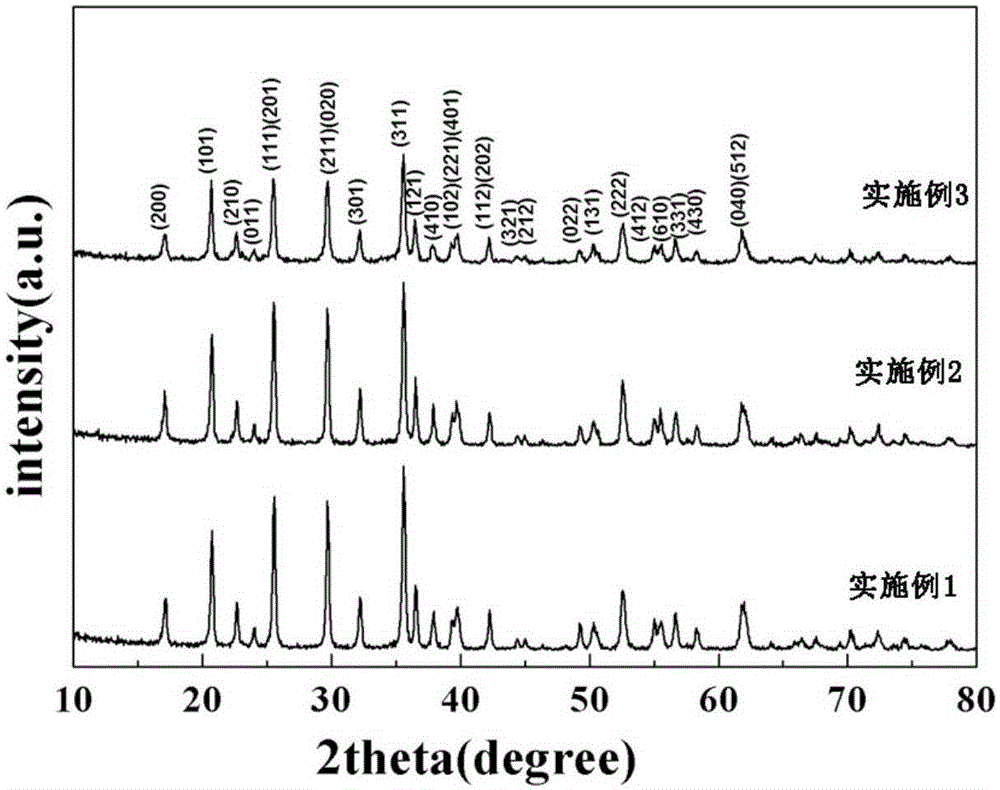

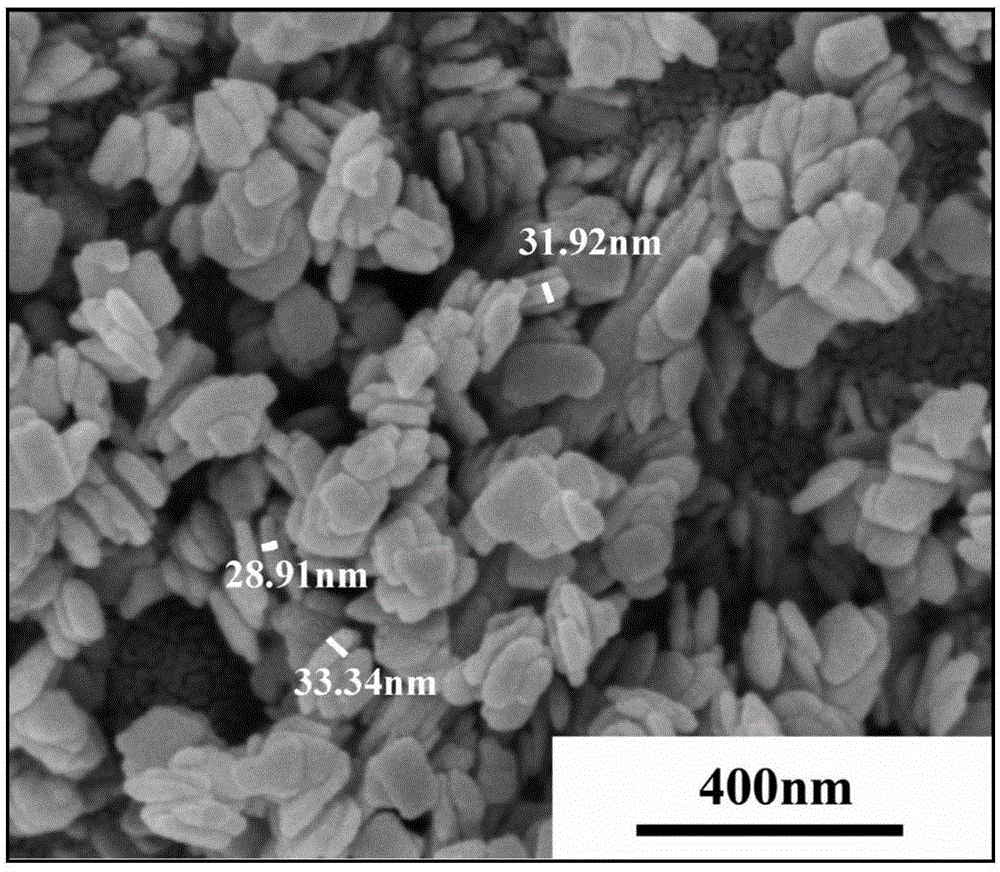

Embodiment 1

[0034]Take 40.5mmol of LiOH.H 2 O was dissolved in 40 ml of ethylene glycol and magnetically stirred. After the solution was dissolved, 22.5 mmol of concentrated phosphoric acid solution was slowly added dropwise while stirring, and a white suspension could be seen. Take 15mmol of FeSO 4 .7H 2 A certain amount of ascorbic acid (FeSO 4 .7H 2 5% wt of O) was completely dissolved in 40 ml of ethylene glycol, then added to the above white suspension while stirring, and stirring was continued for 30 minutes. FeSO 4 .7H 2 O:H 3 PO 4 :LiOH·H 2 O:ethylene glycol was used as a reactant and the molar ratio was 1:1.5:2.7:1.43. The suspension was moved to a closed reaction kettle with a polytetrafluoroethylene lining. The filling degree of the autoclave was 75%. The reaction kettle was placed in a constant temperature blast drying oven, heated to 180 °C for 10 hours, and then cooled to room temperature. . The resulting gray-green precipitate was then washed repeatedly with deio...

Embodiment 2

[0036] Take 40.5mmol of LiOH.H 2 O was dissolved in 65 ml of ethylene glycol and magnetically stirred. After the solution was dissolved, 22.5 mmol of concentrated phosphoric acid solution was slowly added dropwise while stirring, and a white suspended matter could be seen. Take 15mmol of FeSO 4 .7H 2 A certain amount of ascorbic acid (FeSO 4 .7H 2 5% wt of O) was completely dissolved in 65 ml of ethylene glycol, then added to the above white suspension with stirring, and stirring was continued for 45 minutes. FeSO 4 .7H 2 O:H 3 PO 4 :LiOH·H 2 O:ethylene glycol was used as a reactant and the molar ratio was 1:1.5:2.7:2.32. The suspension was moved to a closed reaction kettle with a polytetrafluoroethylene lining. The filling degree of the autoclave was 75%. The reaction kettle was placed in a constant temperature blast drying oven, heated to 180 °C for 10 hours, and then cooled to room temperature. . The resulting gray-green precipitate was then washed repeatedly wit...

Embodiment 3

[0038] Take 40.5mmol of LiOH.H 2 O was dissolved in 80 ml of ethylene glycol and magnetically stirred. After the solution was dissolved, 22.5 mmol of concentrated phosphoric acid solution was slowly added dropwise while stirring, and a white suspended matter could be seen. Take 15mmol of FeSO 4 .7H 2 A certain amount of ascorbic acid (FeSO 4 .7H 2 5% wt of O) was completely dissolved in 80 ml of ethylene glycol, then added to the above white suspension while stirring, and stirring was continued for 60 minutes. FeSO 4 .7H 2 O:H 3 PO 4 :LiOH·H 2 O:ethylene glycol was used as a reactant and the molar ratio was 1:1.5:2.7:2.86. The suspension was moved to a closed reaction kettle with a polytetrafluoroethylene lining. The filling degree of the autoclave was 75%. The reaction kettle was placed in a constant temperature blast drying oven, heated to 180 °C for 10 hours, and then cooled to room temperature. . The resulting gray-green precipitate was then washed repeatedly wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com