A method for enhancing microbial attachment effect in chalcopyrite bioleaching process

A technology of bioleaching and ore leaching microorganisms, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems that leaching microorganisms have not been well studied and the leaching system is complex, and achieve enhanced leaching microorganism adhesion effect, improving leaching efficiency, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

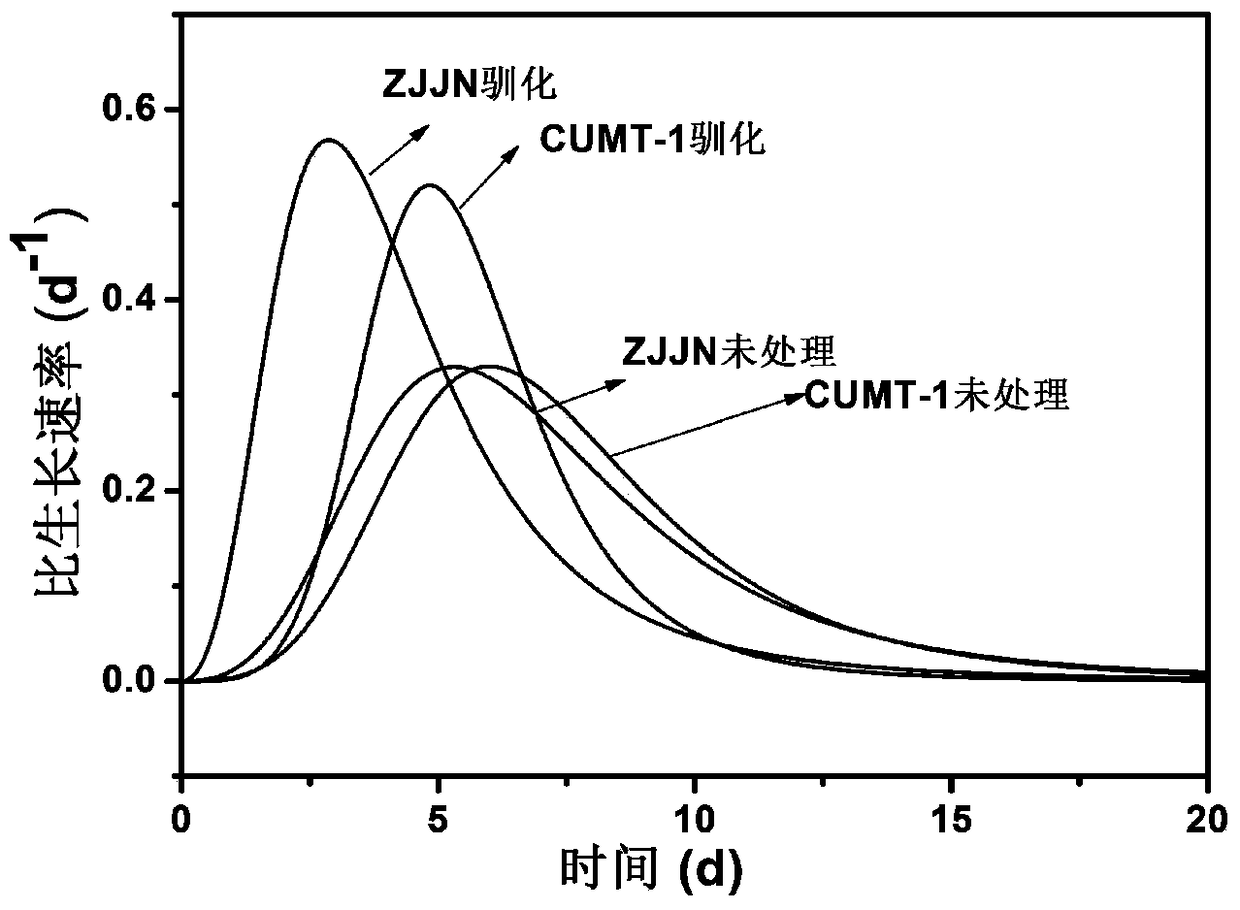

[0026] The determination of the overall bacterial cell concentration in the adsorbed state in the leaching process of different bacterial species chalcopyrite ore of embodiment 1

[0027] The chalcopyrite sample (containing 1.0% copper) comes from the Tongling Mountain mining area in Anhui Province. After preliminary crushing and filtering with a steel sieve, the ore particle size is 7 individual / mL, (NH 4 ) 2 SO 4 3.0g / L, K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, KCl0.1g / L, Ca(NO 3 ) 2 0.01g / L. Thiobacillus thiooxidans ZJJN system: 100mL Starkey medium, cell concentration 5.0×10 7 pieces / ml. (NH 4 ) 2 SO 4 3.0g / L, KH 2 PO 4 3.5g / L, MgSO 4 0.5g / L, CaCl 2 2H 2 O 0.25g / L. The slurry concentration is 3.0%, the temperature is 30° C., and the shaking table rotates at 170 rpm.

[0028]The leaching process and the attached cell washing treatment steps are as follows. After 2 weeks of leaching, the leaching solution was clarified for 1 hour, the supernatant was remo...

Embodiment 2

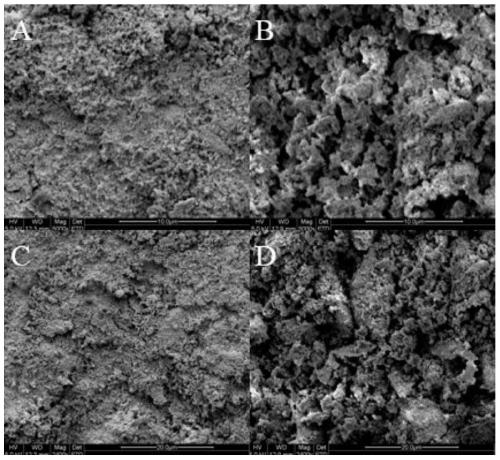

[0032] Example 2 Comparison of the morphology of leached slag before and after treatment with enhanced microbial adhesion effect

[0033] In order to better understand the effect of attached cells after strengthening treatment, the morphology difference of slag before and after strengthening was observed by scanning electron microscope ( figure 2 ). In the system of Thiobacillus ferrooxidans, the slag surface of the untreated system is relatively smoother. However, the surface of slag in the enhanced leaching system is rougher, and there are more traces of adhesion, such as micro pits and ravines. At the same time, it also implies that under the enhanced attachment effect, the metabolism of iron ions is accelerated, and more jarosite precipitation appears on the ore surface. A similar phenomenon also exists in the system of Thiobacillus thiooxidans. With the enhanced adhesion of the attached cells, the "contact" mechanism is strengthened, especially the energy material par...

Embodiment 3

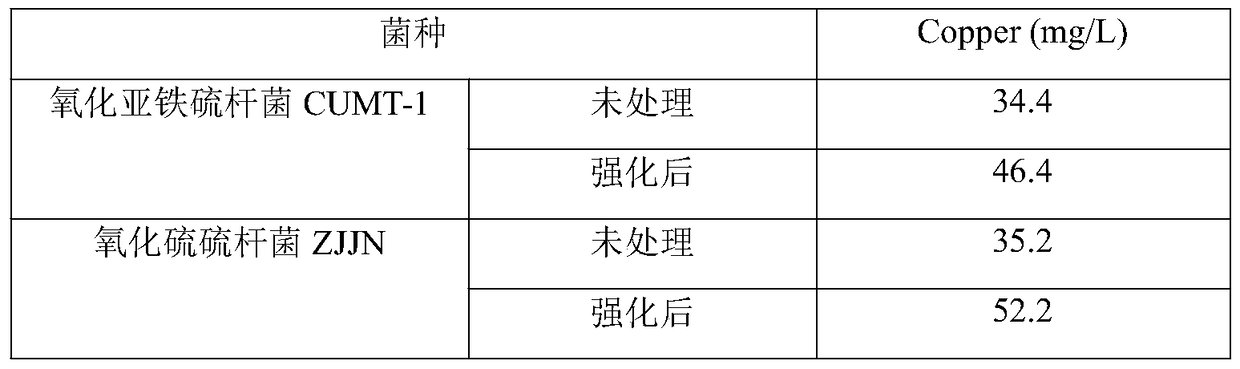

[0034] Embodiment 3 enhances the comparison of leaching efficiency before and after the treatment of microbial adhesion effect

[0035] Table 1 shows the comparison results of leaching efficiency before and after treatment with enhanced microbial attachment effect. In the system of Thiobacillus ferrooxidans CUMT-1, the final copper ion concentration is 34.4 mg / L, and the copper ion concentration after adopting the method of the present invention domesticated is significantly increased to 46.4 mg / L; in the system of Thiobacillus thiooxidans ZJJN , the final copper ion concentration was 35.2mg / L, and the copper ion concentration after domestication was significantly increased to 52.2mg / L. In addition, it has a similar effect on Thiobacillus ferrooxidans ATCC23270.

[0036] Table 1 Comparison of leaching efficiency before and after treatment with enhanced microbial attachment effect

[0037]

[0038] The results show that through the long-term washing treatment and selection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com