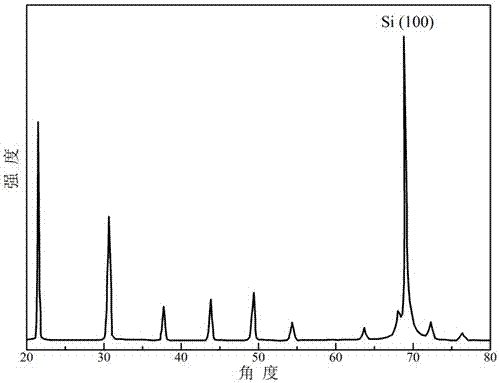

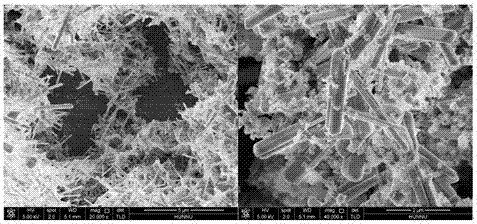

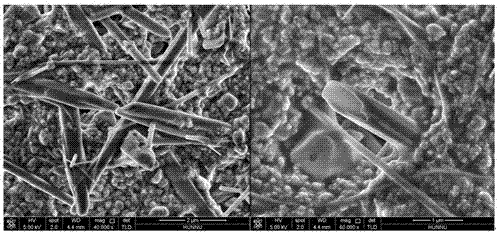

Preparation methods of rare earth and alkaline earth hexaboride nanowires, nanorods and nanotubes

A hexaboride and nanowire technology, applied in the chemical field, can solve problems such as poor morphology, increased production costs, and low output, and achieve the effects of high yield, easy operation, and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 of the present invention: a preparation method of rare earth and alkaline earth hexaboride nanowires, nanorods and nanotubes, comprising the following steps:

[0021] 1) Weigh 0.1g of LaCl 3 and 1.0g of NaBH 4 Put them into different containers respectively, and place the containers containing the metal source and the boron source in the middle of the quartz tube of the tube electric furnace;

[0022] 2) Put the pure substrate on the ceramic boat, and put the ceramic boat into the downflow direction of the quartz tube precursor of the tube electric furnace; seal the quartz tube, and fill it with protective gas, the protective gas is argon, and then tube vacuum;

[0023] 3) Under vacuum conditions, heat the quartz tube to 1050°C at a heating rate of 50°C / min, with a protective gas flow rate of 100 sccm; keep warm for 60 minutes;

[0024] 4) Finally, cool naturally to room temperature in a vacuum atmosphere; take out the substrate and observe directly, the...

Embodiment 2

[0025] Embodiment 2 of the present invention: a preparation method of rare earth and alkaline earth hexaboride nanowires, nanorods and nanotubes, comprising the following steps:

[0026] 1) Weigh 0.2g of LaCl 3 and 1.6g of KBH 4 Put them into different containers respectively, and place the containers containing the metal source and the boron source in the middle of the quartz tube of the tube electric furnace;

[0027] 2) Put the pure substrate on the ceramic boat, and put the ceramic boat into the downflow direction of the quartz tube precursor of the tube electric furnace; seal the quartz tube, and fill it with protective gas, the protective gas is argon, and then tube vacuum;

[0028] 3) Under vacuum conditions, heat the quartz tube to 1070°C at a heating rate of 60°C / min, and the protective gas flow rate is 100 sccm; keep warm for 15 minutes;

[0029] 4) Finally, cool naturally in a vacuum atmosphere until it cools down to room temperature; take out the substrate and o...

Embodiment 3

[0030] Embodiment 3 of the present invention: a preparation method of rare earth and alkaline earth hexaboride nanowires, nanorods and nanotubes, comprising the following steps:

[0031] 1) Weigh 0.1g of CeCl 3 , 0.1g of CaCl 2 , 1.6 g NaBH 4 and KBH 4 Put them into different containers respectively, and place the containers containing the metal source and the boron source in the middle of the quartz tube of the tube electric furnace;

[0032] 2) Put the pure substrate on the ceramic boat, and put the ceramic boat into the downflow direction of the quartz tube precursor of the tube electric furnace; seal the quartz tube, and fill it with protective gas, the protective gas is argon, and then tube vacuum;

[0033] 3) Under vacuum conditions, heat the quartz tube to 1070°C at a heating rate of 30°C / min, and the protective gas flow rate is 60 sccm; keep warm for 20 minutes;

[0034] 4) Finally, cool naturally in a vacuum atmosphere until it cools down to room temperature; tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com