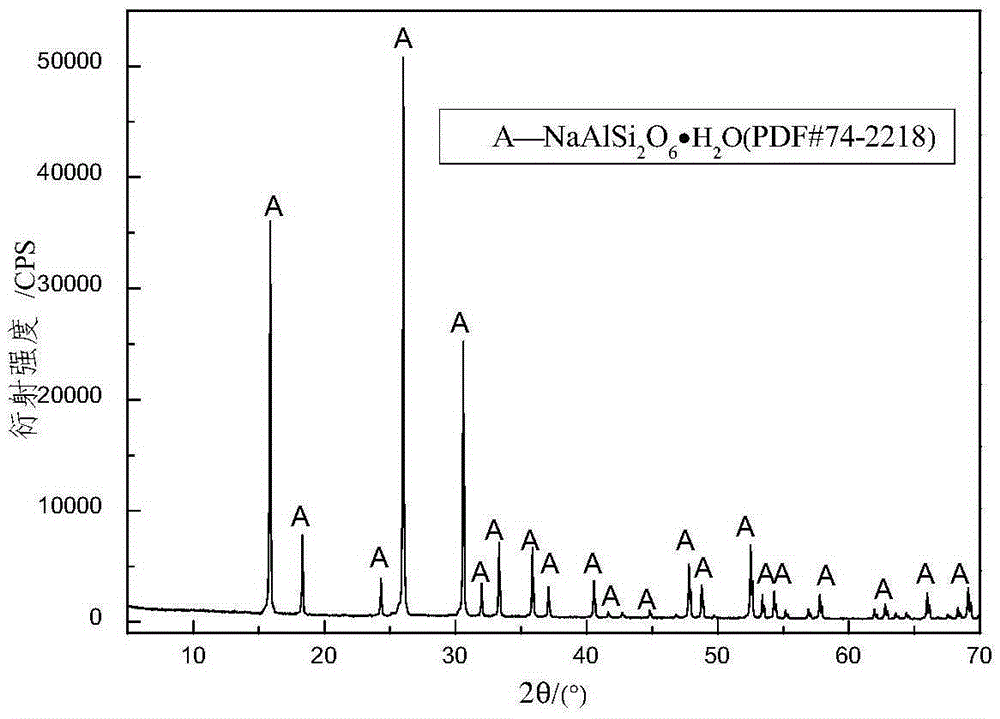

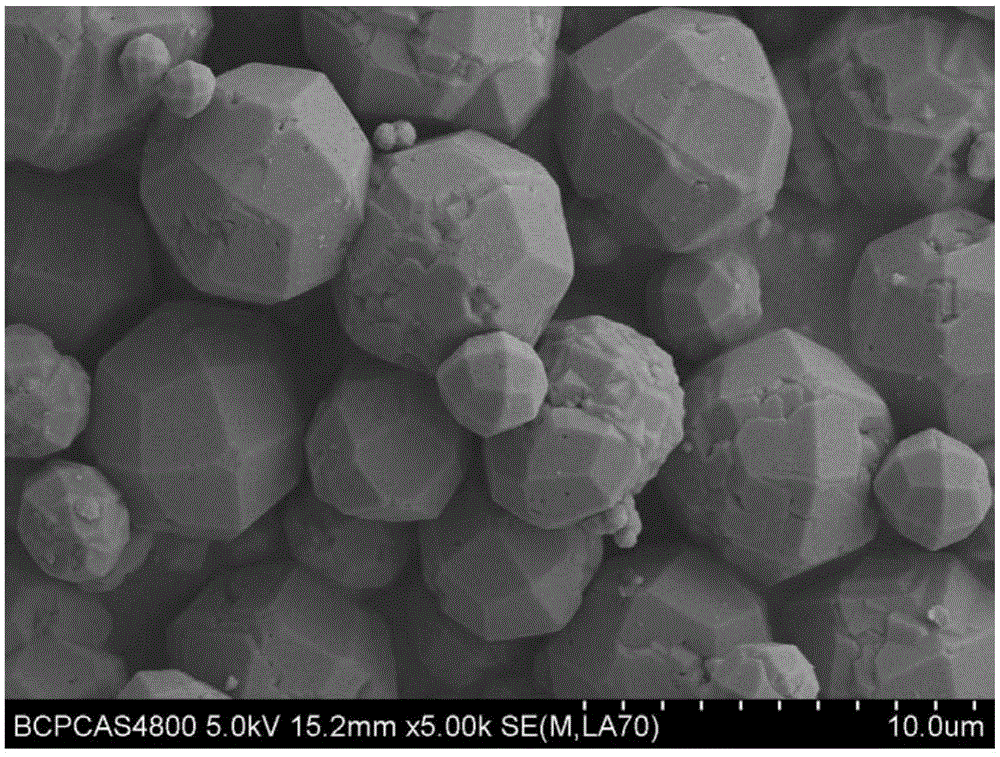

Method for preparing analcite through high-alumina fly ash

A high-alumina fly ash and analcime technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high procurement cost, non-recyclable lye, and complicated process, so as to reduce production costs and solve human health problems. and environmental hazards, the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Pre-desilicate reaction with sodium hydroxide solution and high-alumina fly ash: take 50 grams of high-alumina fly ash with an aluminum-silicon ratio of 1.25, add 200 ml of sodium hydroxide with a sodium oxide concentration of 100 g / L, and place In the reaction kettle, the pre-desilication reaction was carried out at 120°C for 2.0 hours. After the reacted solution was filtered and washed, the liquid phase obtained was the desiliconization lye (the concentration of silicon dioxide was 57.21g / L, and the concentration of sodium oxide was 87.4g / L, alumina concentration 1.53g / L, Na 2 o c concentration 5.8g / L), the solid phase is desiliconized fly ash;

[0035] 2) Add the desiliconized fly ash obtained in 1) to the slurry made of sodium carbonate and limestone to obtain a mixed slurry, sinter the mixed slurry to form clinker, and then go through the clinker dissolution process to obtain a sodium aluminate solution (alumina concentration is 102.36g / L, sodium oxide concent...

Embodiment 2

[0039] 1) Use sodium hydroxide solution and high-alumina fly ash for pre-desilication reaction: take 50 grams of high-alumina fly ash with an aluminum-silicon ratio of 1.17 and add 150 ml of sodium hydroxide with a sodium oxide concentration of 80 g / L, place In the reaction kettle, the pre-desilication reaction was carried out at 120°C for 1.5 hours. After the reacted solution was filtered and washed, the liquid phase obtained was the desiliconization lye (the concentration of silicon dioxide was 49.87g / L, and the concentration of sodium oxide was 76.7g / L, alumina concentration 1.67g / L, Na 2 o c Concentration 6.8g / L), the solid phase is desiliconized fly ash;

[0040] 2) Add the desiliconized fly ash obtained in 1) to the slurry made of sodium carbonate and limestone to obtain a mixed slurry, sinter the mixed slurry to form clinker, and then go through the clinker dissolution process to obtain a sodium aluminate solution (the concentration of aluminum oxide is 95.47g / L, the ...

Embodiment 3

[0043] 1) Pre-desiliconization reaction with sodium hydroxide solution and high-alumina fly ash: take 50 grams of high-alumina fly ash with an aluminum-silicon ratio of 1.06, add 200 ml of sodium hydroxide with a sodium oxide concentration of 110 g / L, and place In the reaction kettle, the pre-desilication reaction was carried out at 130°C for 2.0 hours. After the reacted solution was filtered and washed, the liquid phase obtained was the desiliconization lye (the concentration of silicon dioxide was 60.23g / L, and the concentration of sodium oxide was 85.41g / L, alumina concentration 0.94g / L, Na 2 o c Concentration 7.2g / L), the solid phase is desiliconized fly ash;

[0044] 2) Add the desiliconized fly ash obtained in 1) to the slurry made of sodium carbonate and limestone to obtain a mixed slurry, sinter the mixed slurry to form clinker, and then go through the clinker dissolution process to obtain a sodium aluminate solution (alumina concentration is 110.36g / L, sodium oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com