Preparation method of hydrous ruthenium dioxide for resistance slurry

A resistance paste, ruthenium dioxide technology, applied in chemical instruments and methods, inorganic chemistry, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, etc. problems such as large expenses and equipment costs, to achieve the effect of uniform particle size, easy operation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

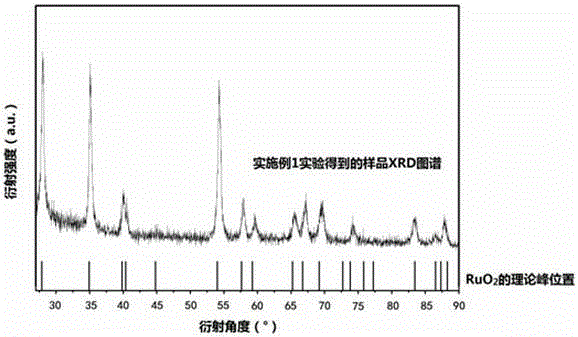

Embodiment 1

[0025] First weigh 1.003g of ruthenium trichloride, dissolve it in 100mL of deionized water and mix evenly to make a solution, then add 0.3mL of hydrochloric acid with a mass fraction of 37% dropwise into the solution, and heat and stir with a constant temperature magnetic stirrer to make the trichloride The ruthenium chloride is hydrolyzed into a ruthenium chloride solution for use.

[0026] Weigh 0.8g of sodium hydroxide, dissolve it in 100mL of deionized water and mix well to make a sodium hydroxide solution.

[0027] Next, slowly pour the prepared ruthenium chloride solution into the sodium hydroxide solution until a large amount of black flocculent precipitates appear in the solution, then stop adding the ruthenium chloride solution, and then add hydrochloric acid solution dropwise to adjust the pH to neutral. There will be obvious solid-liquid delamination, pour off the supernatant, and filter the remaining solution through a sand core funnel. Repeatedly add hot water to...

Embodiment 2

[0031] First weigh 1.003g of ruthenium trichloride, dissolve it in 100mL of deionized water and mix evenly to make a solution, then add 0.3mL of hydrochloric acid with a mass fraction of 37% dropwise into the solution, and heat and stir with a constant temperature magnetic stirrer to make chlorine Ruthenium acid solution.

[0032] Weigh 0.73g sodium hydroxide, dissolve it in 100mL deionized water and mix well to make a solution

[0033] Next, slowly pour the chlororuthenic acid solution into the sodium hydroxide solution, stop adding the chlororuthenic acid solution until a large amount of black flocculent precipitates appear in the solution, then add the hydrochloric acid solution dropwise to adjust the pH to neutral, suction filter, and use hot water to Wash and dry in an oven at 90°C to obtain ultrafine hydrated ruthenium dioxide.

Embodiment 3

[0035] First weigh 100.0g of ruthenium trichloride, dissolve it in 1000mL of deionized water and mix evenly to make a solution, then add 30mL of hydrochloric acid with a mass fraction of 37% dropwise into the solution, and heat and stir with a constant temperature magnetic stirrer to make ruthenium chloride acid solution. At the same time, weigh 80g of sodium hydroxide, dissolve it into 1000mL of deionized water and mix it evenly to make a solution; then slowly pour the chlororuthenic acid solution into the sodium hydroxide solution until a large amount of black flocculent precipitates appear in the solution, then stop adding Chlororuthenic acid solution, then add hydrochloric acid solution dropwise to adjust the pH to 6-7, the reaction temperature is 60°C, use a sand core funnel to filter, wash with hot deionized water, place in a 90°C oven, and turn the sand core funnel upside down After drying, the superfine hydrated ruthenium dioxide can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com