Composite modified mortar for air-entrained bricks

A composite modified, aerated brick technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Wall leakage, high water absorption of mortar, etc., to achieve the effect of low cost, low thermal conductivity and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

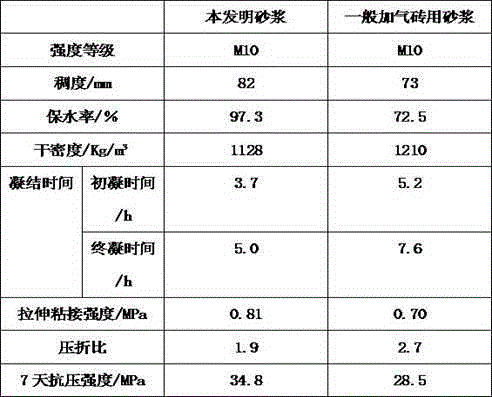

Image

Examples

Embodiment Construction

[0023] A composite modified aerated brick mortar, which is made of the following components by weight percentage: 58% of quartz sand, 11% of fly ash, 4% of glass fiber, 2% of diatomite, 3% of bentonite, and 4.5% of quicklime , 9% cement, 2% aluminum powder, 4.5% redispersible latex powder, 1% superplasticizer, and 1% additive.

[0024] Further, the quicklime and aluminum powder need to be calcined and ground at a temperature of 180-200°C for 2-3 hours.

[0025] Further, the redispersible latex powder is acrylate and styrene copolymer powder.

[0026] Further, the water reducer is a melamine-based water reducer.

[0027] Further, the additive is cellulose ether.

[0028] Further, the diatomite undergoes process modification: soak the diatomite in 1% hydrochloric acid for 30 minutes, filter, then soak in 5% sodium hydroxide solution, heat and grind for 30-40 minutes , naturally cooled to room temperature, filtered, and dried.

[0029] Further, the cement is calcined: adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com