A kind of biodegradable material and its preparation method and application

A technology of polylactic acid and seedling container, which is applied in application, cultivation, agriculture, etc., can solve the problems of high cost, slow degradation time, and incomplete degradation of seedling container, and achieve the effect of low cost, simple product and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

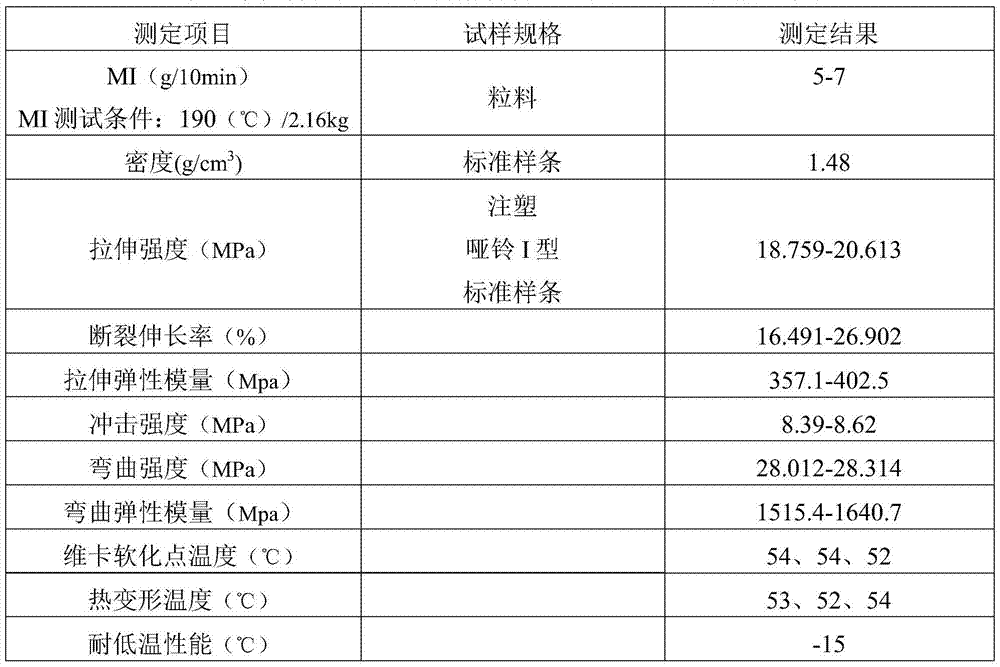

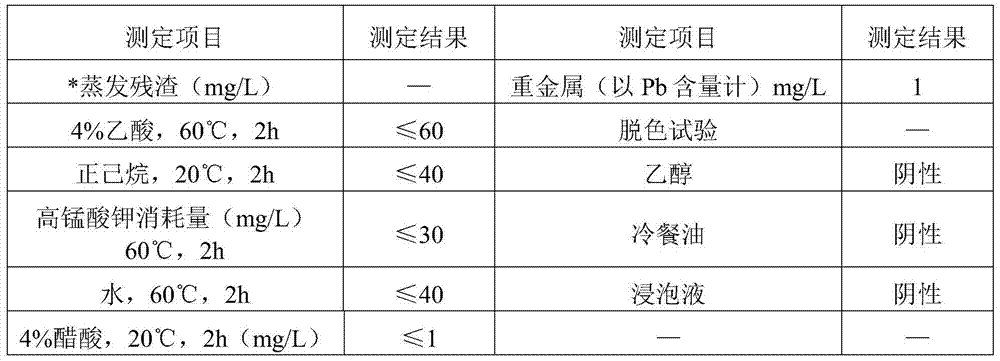

Examples

Embodiment 1

[0039] The biodegradable material described in this embodiment is made of the following components: polylactic acid 60kg, starch 14kg, PBAT 10kg, talcum powder 5kg, carboxymethyl cellulose 5kg, polycaprolactone 2kg, sorbitol 1.5kg, tributyl citrate Esters 5kg, 2,2-methylene bis(4-methyl-6-tert-butylphenol) 0.4kg, carbodiamine 0.5kg, styrene-methyl methacrylate-glycidyl methacrylate tri 0.5kg meta-copolymer, 0.5kg stearic acid, 0.5kg erucic acid, 0.5kg epoxy soybean oil, 0.3kg calcium stearate.

[0040] The preparation method of the biodegradable seedling raising container of this embodiment includes the following steps: adding starch and talcum powder to a high-speed mixer for mixing, the running time is 10 minutes, the speed of the high-speed mixer is 280 rpm, and the temperature inside the machine is 95°C; Put the mixture of talcum powder and starch into the cooling mixer. The speed of the cooling mixer is 300 rpm to cool the material below 40°C, and add polylactic acid, PBA...

Embodiment 2

[0043] The biodegradable material described in this embodiment is made of the following components: polylactic acid 50kg, tapioca starch 14kg, PBAT 15kg, talcum powder 10kg, carboxymethyl cellulose 5kg, polycaprolactone 2kg, sorbitol 1.5kg, tricitric acid Butyl ester 4.5kg, 2,2-methylenebis(4-methyl-6-tert-butylphenol) 0.6kg, styrene-glycidyl methacrylate copolymer 0.5kg, carbodiamine 0.5kg, Stearic acid 0.5kg, oleic acid 0.6kg, epoxy soybean oil 0.5kg, calcium stearate 0.3kg.

[0044] The preparation method of the biodegradable seedling raising container of this embodiment includes the following steps: adding starch and talcum powder to a high-speed mixer for mixing, the running time is 20 minutes, the speed of the high-speed mixer is 320 rpm, and the temperature inside the machine is 120°C; Put the talcum powder and starch into the cooling mixer, the speed of the cooling mixer is 600 rpm to cool the material below 40°C, add polylactic acid, PBAT and various additives, and ad...

Embodiment 3

[0047] The biodegradable material described in this embodiment is made of the following components: polylactic acid 45kg, cornstarch 5kg, PBAT 20kg, calcium carbonate 26kg, carboxymethyl cellulose 9kg, polycaprolactone 2kg, triacetin 3kg, 2, 2-methylenebis(4-methyl-6-tert-butylphenol) 0.9kg, styrene-glycidyl methacrylate copolymer 0.5kg, carbodiamine 0.5kg, epoxy compound 2kg, stearin Acid 0.5kg, ethylene bis stearic acid amide 0.5kg, epoxy soybean oil 0.5kg, calcium stearate 0.3kg.

[0048] The preparation method of the biodegradable seedling raising container of this embodiment includes the following steps: adding starch and talcum powder to a high-speed mixer for mixing, the running time is 15 minutes, the speed of the high-speed mixer is 300 rpm, and the temperature inside the machine is 105°C; Put the talcum powder and starch into the cooling mixer, the speed of the cooling mixer is 450 rpm to cool the material below 40°C, add polylactic acid, PBAT and various additives, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com